Secondary fermentation method and device of Pu'er tea

A technology of secondary fermentation and Pu-erh tea, which is applied in the field of secondary fermentation of tea, and can solve problems such as inability to obtain quality, poor taste and aroma of tea, and uneven products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

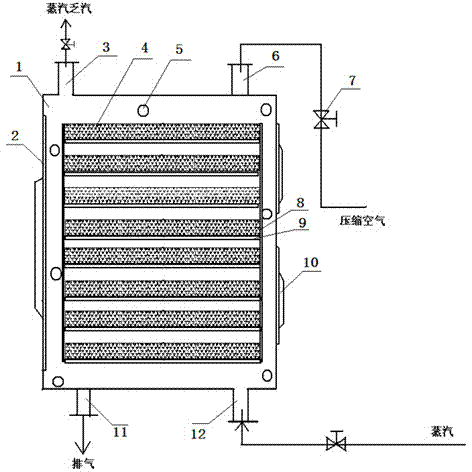

Image

Examples

Embodiment 1

[0024] Put 1000kg of Pu'er tea that has been fermented once on a tray, and place the trays on the brackets layer by layer. In the tea room, the temperature is controlled at 50-55°C for 5-10 hours, and then the steam supply is stopped, and the tea leaves are fermented in a closed fermentation room for 3-5 days (no need to add any strains, relying on the tea itself when it is first fermented) The beneficial bacteria contained in it reproduce by themselves), the fermentation temperature is maintained at 40-50°C, if the temperature is too high or too low, steam or ventilation is controlled, and after the fermentation is completed, there is a layer of light yellow or light yellow on the surface of the tea leaves. The golden mycelium that has a health care effect on the human body opens the door of the fermentation room, ventilates, and allows the temperature of the tea leaves to cool and dry naturally for 3 to 5 days to obtain high-quality Pu'er tea for secondary fermentation.

Embodiment 2

[0026]Put 1000kg of Pu'er tea leaves that have been fermented once on a tray, and place the trays on the bracket layer by layer. In the tea room, the temperature is controlled at 55-60°C for 10-15 hours, and then the steam supply is stopped, and the tea leaves are fermented in a closed fermentation room for 3 to 5 days (no need to add any strains, relying on the tea itself when it is first fermented) The beneficial bacteria contained in it reproduce by themselves), the fermentation temperature is maintained at 40-50°C, if the temperature is too high or too low, steam or ventilation is controlled, and after the fermentation is completed, there is a layer of light yellow or light yellow on the surface of the tea leaves. The golden mycelium has a health care effect on the human body, open the door of the fermentation room, ventilate, let the temperature of the tea leaves cool and dry naturally for 4-6 days, if the weather is relatively humid, you can use hot air to dry properly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com