Absorbable anti-adhesive membrane for cardiac surgery and preparation method of absorbable anti-adhesive membrane

A technique for cardiac surgery and anti-adhesion film, applied in the field of medical materials, can solve the problems of complex preparation method, unsuitable for industrial production, increased cost, etc., and achieves the advantages of inhibiting the growth of fibroblasts, saving medical expenses and preventing the occurrence of adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the preparation process of the above-mentioned absorbable anti-adhesion film for cardiac surgery, the ring-opening reaction of lactide occurred in step 1), and the chemical equation is as follows:

[0053]

[0054] Step 2) A chain extension reaction occurs, and the chemical equation is as follows:

[0055]

[0056] Here m and n are determined according to the addition amount of lactide and polyethylene glycol, and the equation is used to illustrate the mechanism of the reaction vividly. The specific numerical values of m and n can refer to the numerical values of the examples.

[0057] The present invention also provides another method (method 2) for preparing the above-mentioned absorbable anti-adhesion film for cardiac surgery, which may include the following steps:

[0058] 1) Weigh the refined polyethylene glycol, place it in a reaction vessel, seal it, heat it at 100-150°C (preferably 140°C), and add lactide (lactide and poly The molar ratio of ethyle...

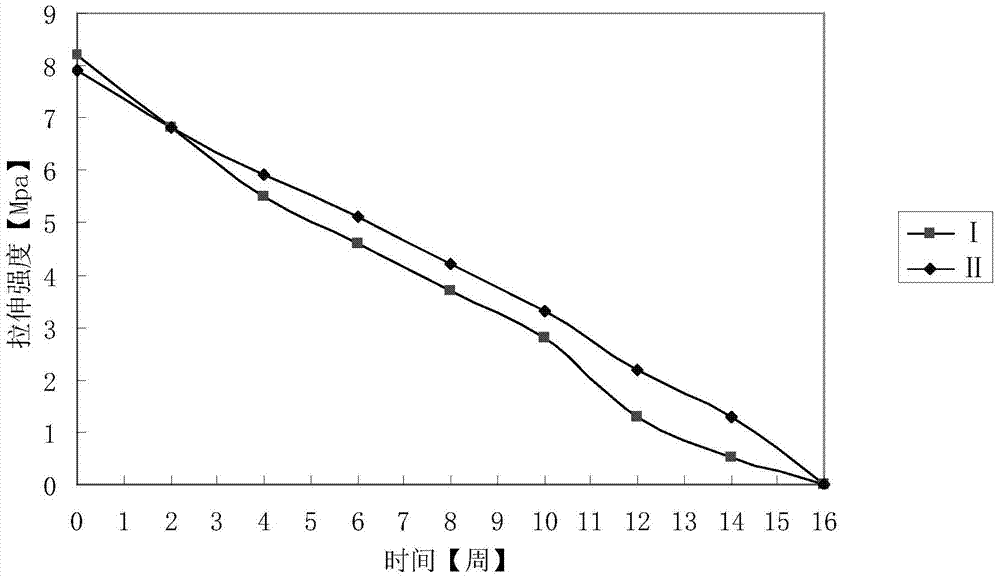

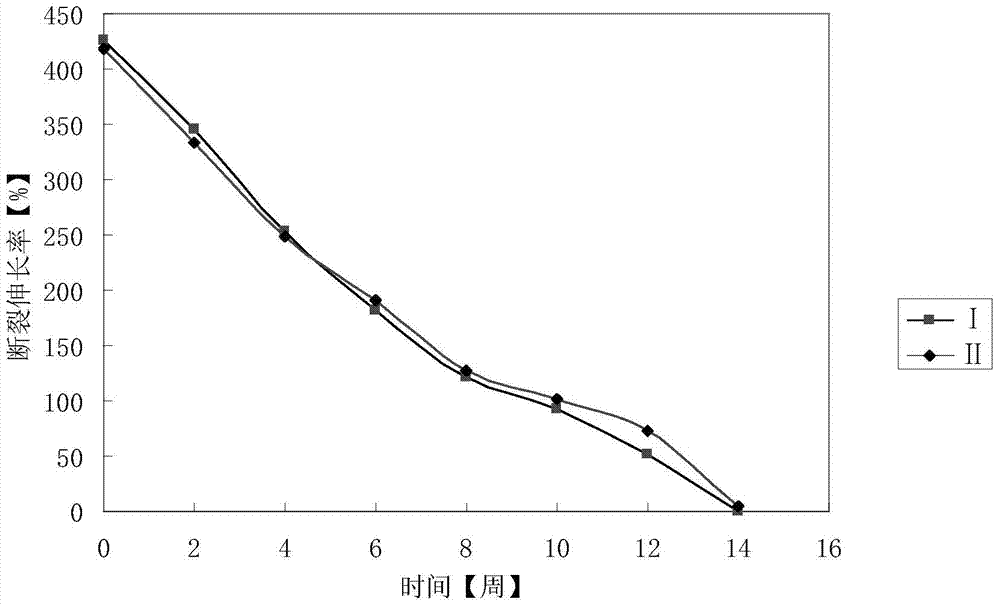

Embodiment 1-6 and comparative example 1

[0078] Examples 1-6 The absorbable anti-adhesion film used in heart surgery of the present invention, the components of Comparative Example 1 and the process parameters of Preparation Method 1 are shown in Table 1-1.

[0079] Table 1-1

[0080]

[0081]

[0082] The components of the absorbable anti-adhesion film used for heart surgery in Examples 1-6 of the present invention and Comparative Example 1 and the process parameters of Preparation Method 1 are shown in Table 1-1. Taking Example 1 as an example, the present invention implements The preparation method of example 1-6 and comparative example 1 comprises the following steps:

[0083] 1) Weigh 30.0g (0.0030 mole) of refined polyethylene glycol and place it in a 250mL three-necked flask, seal it, heat it at 100°C, and after it melts, add 70.0g (0.486 mole) of lactide, and lactide The molar ratio of ester to polyethylene glycol is 162:1, after melting, add catalyst stannous octoate (Sn(oct) 2 ) 0.020g (0.000049 mol...

Embodiment 7-12 and comparative example 2

[0106] Examples 7-12 The absorbable anti-adhesion film used in heart surgery and the components of Comparative Example 2 and the process parameters of the second preparation method are shown in Table 2-1.

[0107] table 2-1

[0108]

[0109] The components of the absorbable anti-adhesion film used for heart surgery in Examples 7-12 of the present invention and Comparative Example 2 and the process parameters of Preparation Method 1 are shown in Table 2-1. Taking Example 7 as an example, the present invention implements The preparation method of example 7-12 and comparative example 2 comprises the following steps:

[0110] 1) Weigh 15.0g (0.0015 mole) of refined polyethylene glycol and place it in a 250mL three-neck flask, seal it, heat it at 100°C, and after it melts, add 70.0g (0.486 mole) of lactide, lactide The molar ratio of ester to polyethylene glycol is 324:1, after melting, add catalyst stannous octoate (Sn(oct) 2) 0.020g (0.000049 moles), the amount of catalyst i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| suture strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com