Transverse distribution lamella purifier and settling pond with same

A purification device and inclined plate settlement technology, which is applied in the direction of the settlement tank, etc., can solve the problems of long time required and low water purification efficiency, and achieve the effects of reducing dosage, improving purification efficiency, and improving purification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

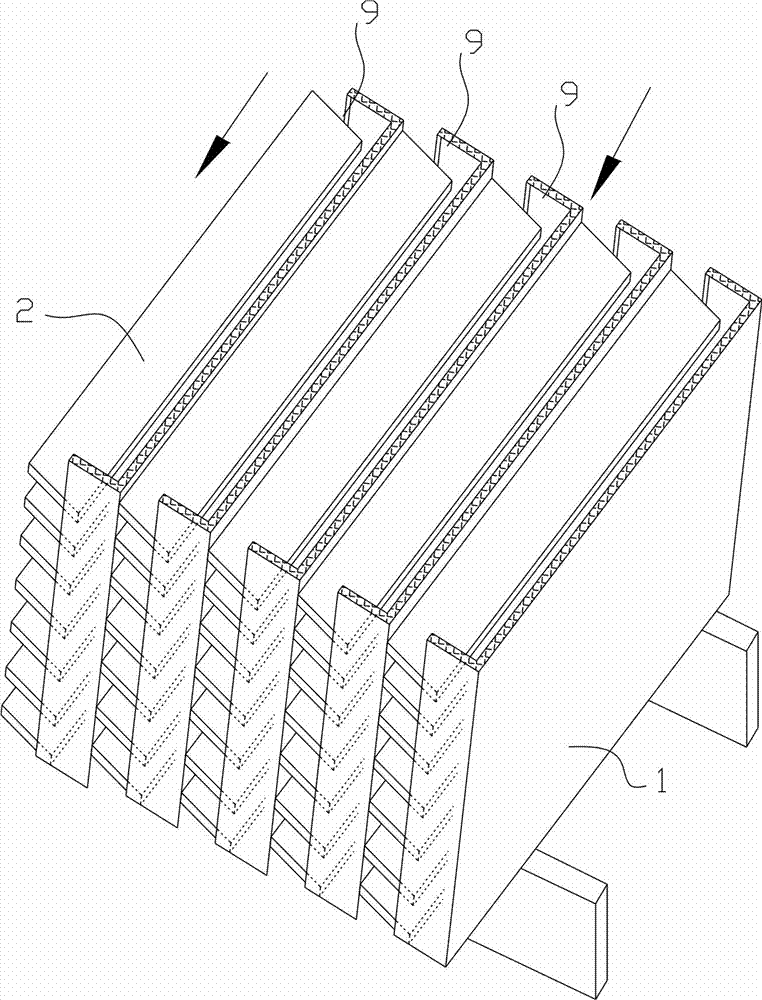

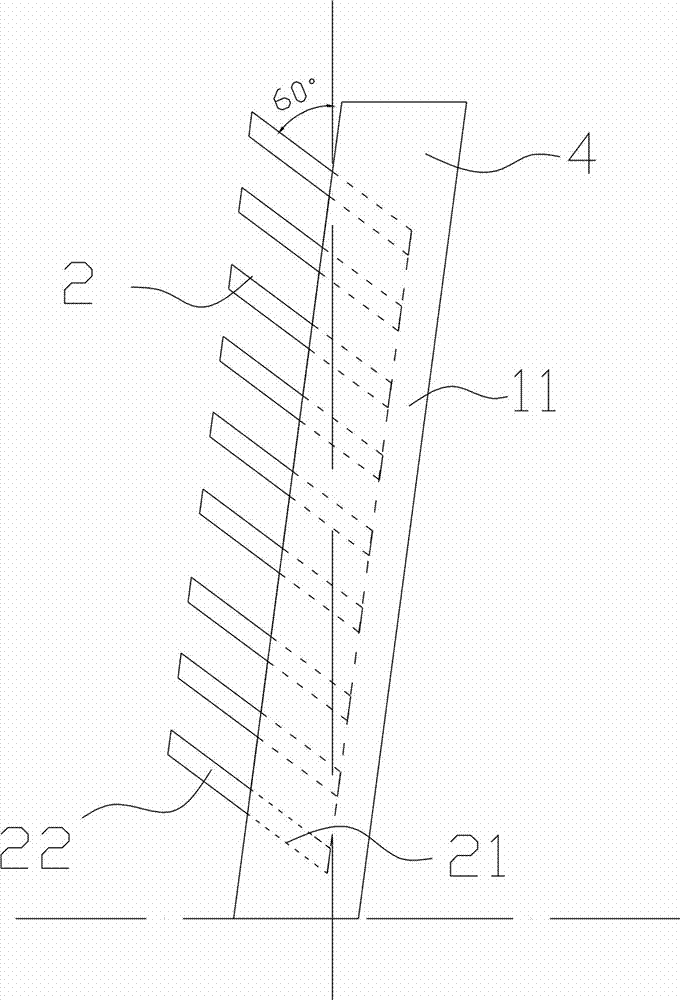

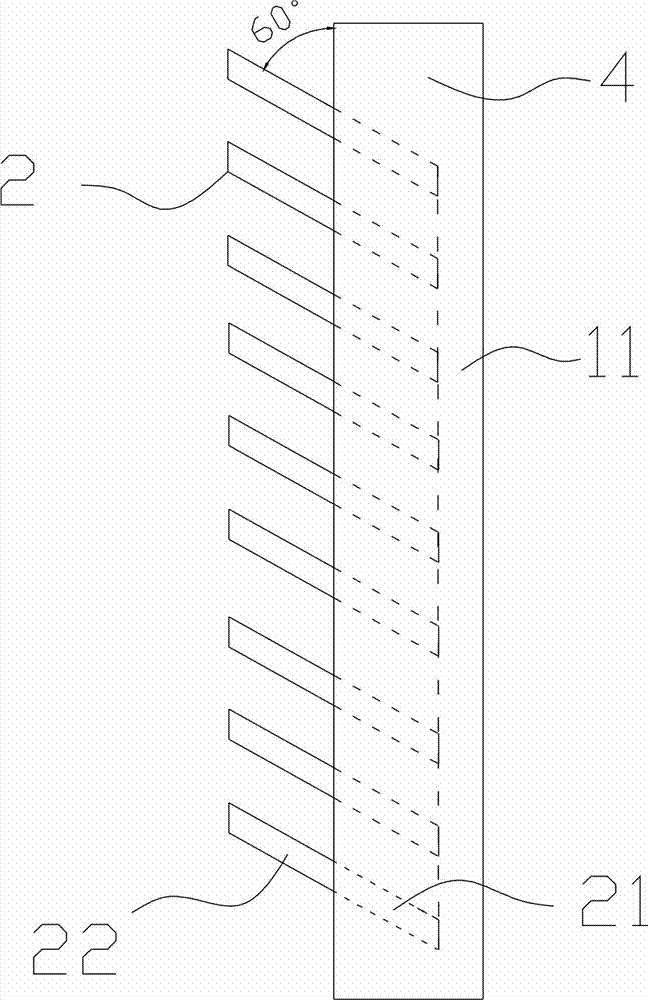

[0021] Such as figure 1 As shown, a horizontal split-type sloping plate purification device is formed by arranging multiple sets of sedimentation parts 9 in sequence, or the sedimentation parts include a deflector 1, a plurality of wing plates 2, a first baffle 3 and a second The baffle 4, the baffle is used to guide the sediment to flow downward, and the flap is arranged along the fluid flow direction, while the fluid flow direction in the present invention is the horizontal direction, so the flap is also arranged along the horizontal direction, the first baffle The plate 3 and the second baffle 4 are arranged on the front and rear sides of the baffle 1 respectively, and the two baffles are arranged perpendicular to the fluid flow direction, after the fluid flows in from the inlet end, flows through the first baffle and flows to the second baffle Two baffles; the two baffles and the deflector form a similar U-shaped frame, and the wing plate is just placed in the middle of th...

Embodiment 2

[0026] Such as Figure 5 Shown, a kind of horizontal split type inclined plate settling tank comprises tank body 5, and the right side of tank body 5 is provided with the inlet 51 that flows into for medium, is provided with the separation area 52 that separates for fluid and sediment in the tank body, for sediment In the sedimentation area 53, the left side of the pool body is provided with an outlet 54 for the fluid to flow out, and the outlet 54 is connected to a sump 55 perpendicular to the direction of fluid circulation. Specifically, the sump is long and runs along the left side of the pool body. The side edge is arranged, and the purified one flows into the sump through the through hole on the sump wall, and then flows out through the outlet 54; preferably, the settling area has a funnel-shaped outlet 531, which is convenient for sediment discharge; There is the purification device in Embodiment 1. The specific structure of the purification device will not be described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com