Method for manufacturing pure titanium porous structure through selective laser melting

A technology of laser melting and porous structure, which is applied in the field of porous structure manufacturing, can solve problems such as not being able to form at one time, achieve the effect of overcoming unstable mechanical properties, improving processing efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

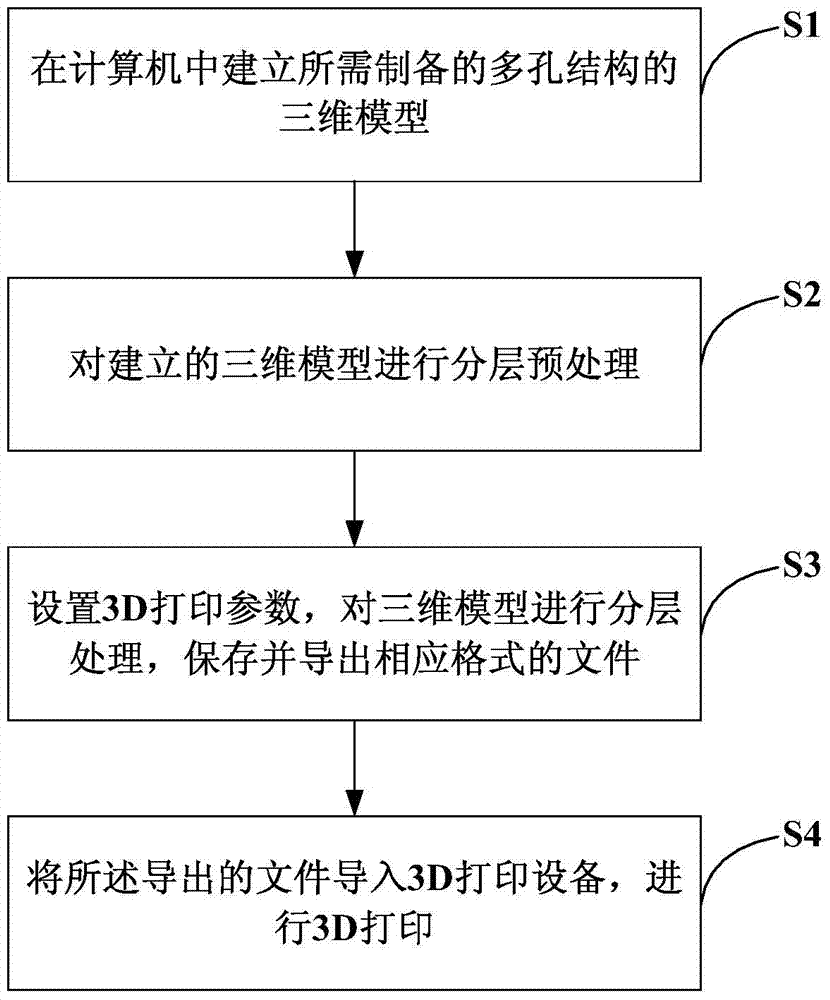

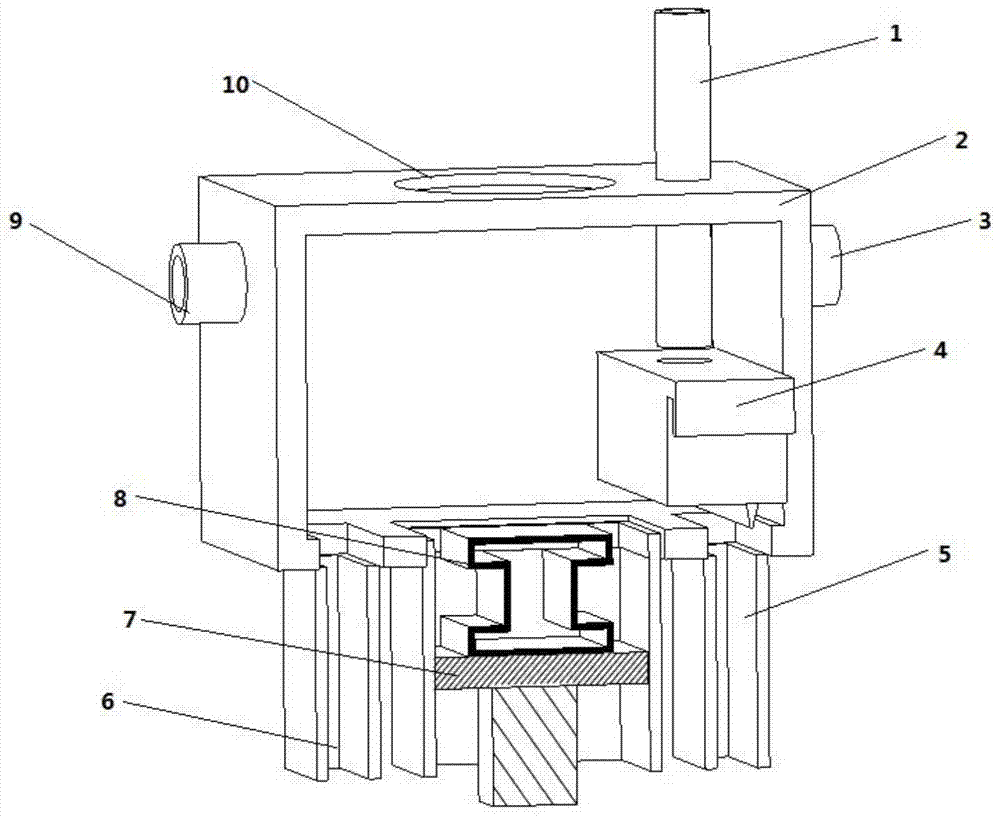

[0027] like figure 1 As shown, the present invention provides a kind of method that selective laser melting prepares pure titanium porous structure, and it adopts the 3D printing equipment that the model that Germany SLM Solutions Gmbh company produces is SLM-125HL, and the supporting software that uses is that this equipment comes with SLM AutoFab MCS1.1 or SLM AutoFab641.8 software.

[0028] Described method specifically comprises the following steps:

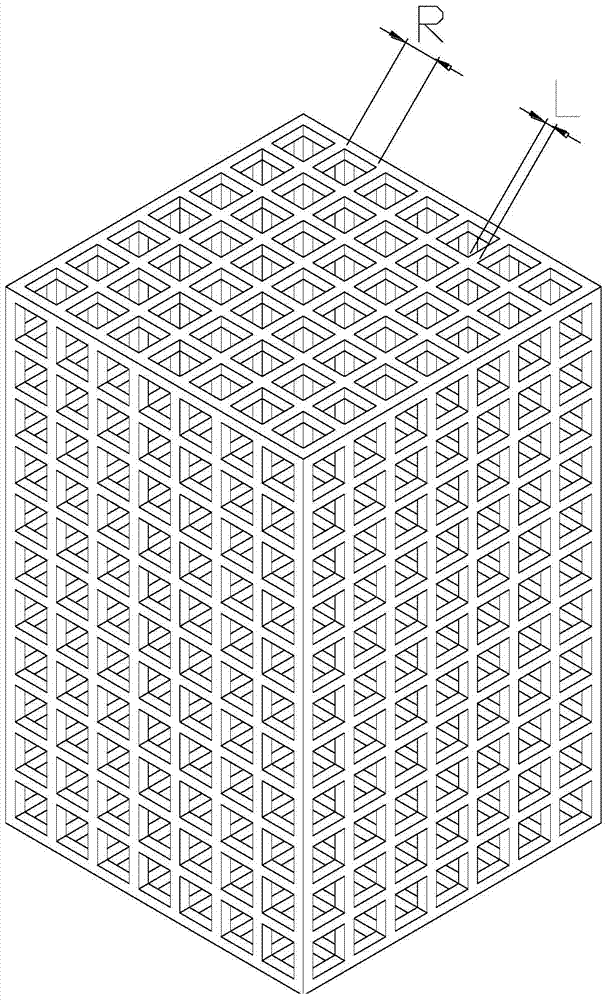

[0029] S1. Establish the three-dimensional model of the porous structure to be prepared in the computer; according to the actual structure of the parts to be prepared, use engineering drawing software such as solidworks, UG, ProE, etc. to design and establish the three-dimensional model of the actual porous structure, and save it as STL format. Among them, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com