Automatic feeding device of wheel body type workpiece machine tool

An automatic feeding and workpiece technology, applied in metal processing and other directions, can solve the problems of complex structure, high degree of automation and high risk, and achieve the effect of simple structure, high degree of automation and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

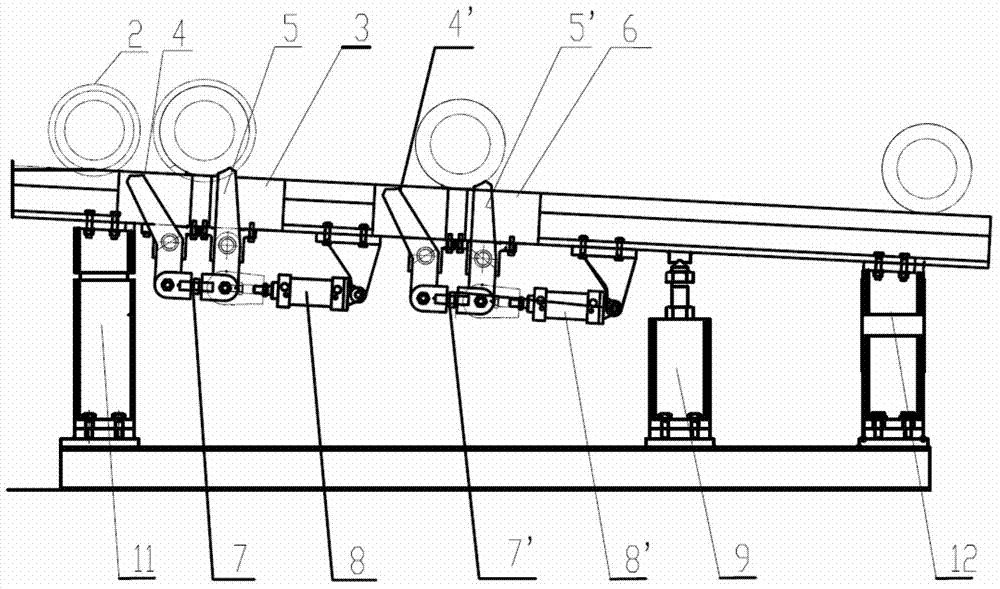

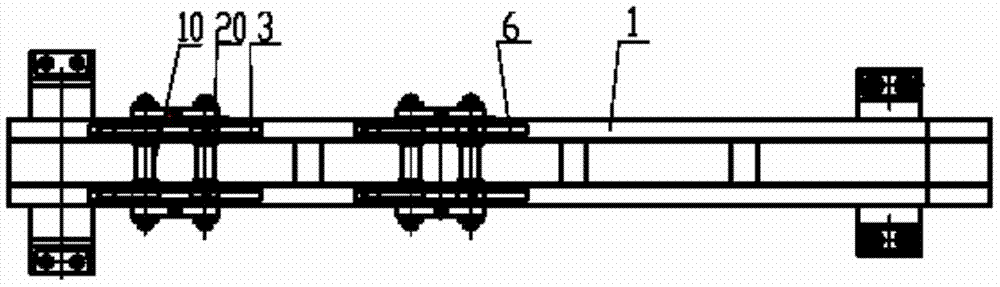

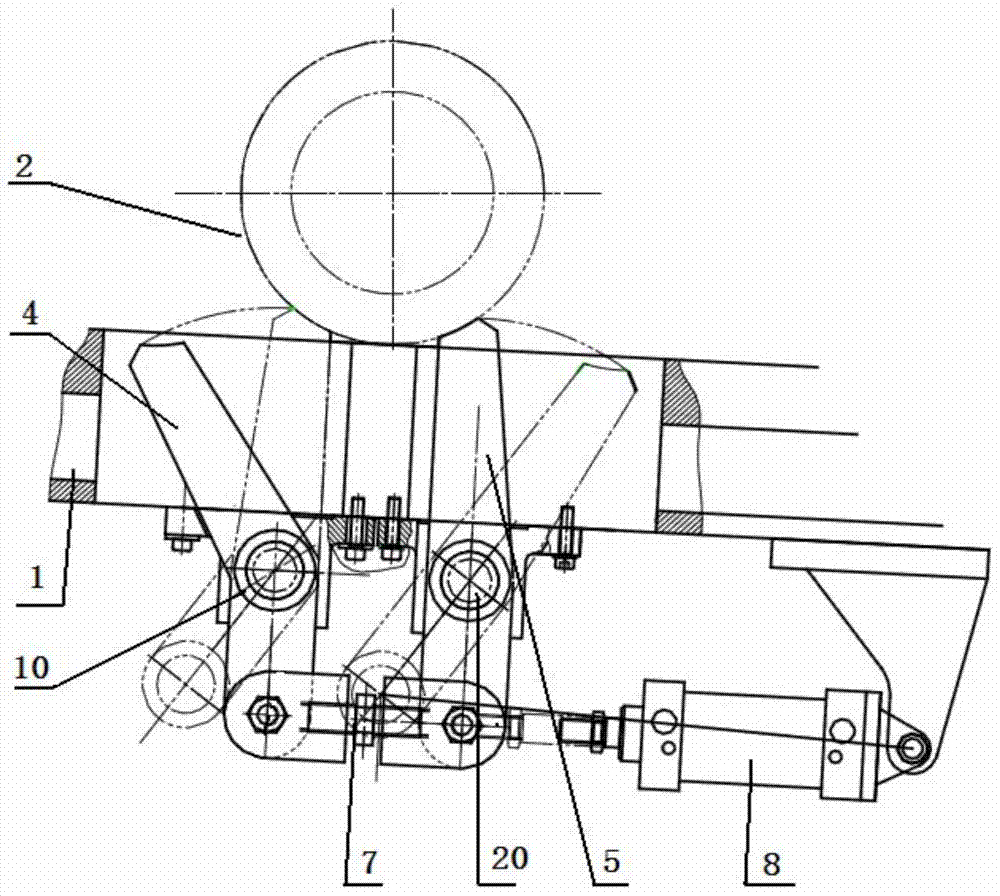

[0012] The automatic feeding device for wheel-type workpiece machine tools disclosed in the patent application of the present invention is a conveying and feeding device that can cooperate with various medium and large-volume wheel-type workpiece processing machine tools, such as wheel hub quenching processing machine tools. The wheel body type workpiece refers to a workpiece to be machined with a cylindrical outer surface, or a nearly cylindrical outer surface, or a circumferential outer surface.

[0013] The composition of the automatic feeding device of the wheel-type workpiece machine tool includes a conveying platform guide rail 1, the support part of the conveying platform guide rail 1 makes the conveying platform 1 in an inclined state, and the inclination angle of the conveying platform guide rail 1 enables the workpiece 2 to be processed on the conveying platform guide rail 1. It rolls and moves by itself, so that the workpiece 2 to be processed is sent step by step fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com