Surface high-frequency vibration conformal machining device and method for optical element

A technology of high-frequency vibration and optical components, which is applied in the field of advanced optical manufacturing, can solve the problems of unsatisfactory processing of deep concave free-form surface components, low precision polishing efficiency, and low removal efficiency, and achieve simple structure, low cost, and effective removal of medium and high The effect of frequency error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

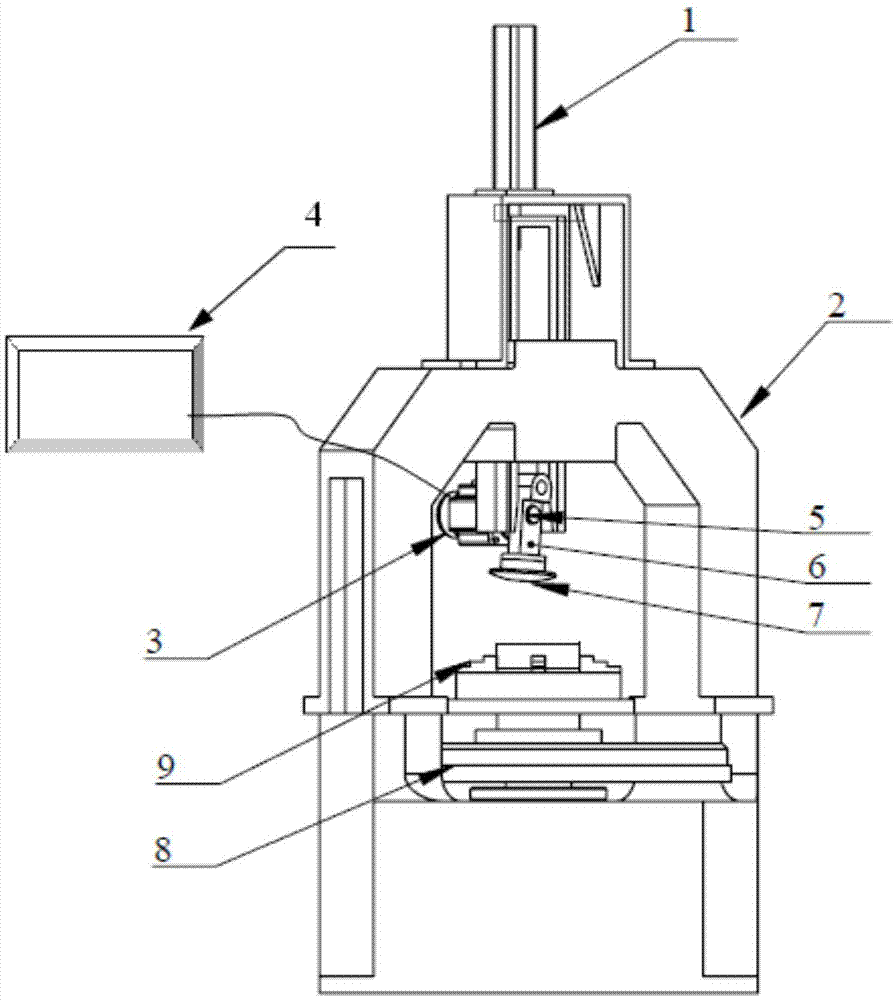

[0024] Example 1: Combining figure 1 The high-frequency vibration conformal polishing device illustrates this embodiment. This embodiment includes a precision cylinder 1, a gantry 2, a high-speed motor 3, a precision frequency converter 4, a cam 5, a swing arm 6, a grinding head 7, a rotary table 8 and the Workpiece 9. Precision cylinder 1, high-speed motor 3, cam 5, swing arm 6 and grinding head 7 are fixed on the gantry 2; gantry 2 is fixed directly above the rotary table 8; grinding head 7 is fixed directly below the swing arm; swing arm 6 is fixed On the cam 5; the high-speed motor 3 is connected to the cam 5, and the high-speed motor 3 drives the cam 5 to rotate; the rotation of the cam 5 drives the swing arm 6 to swing, so that the grinding head 7 fixed under the swing arm swings at a certain swing; the precision cylinder 1 Control the up and down movement of the cam 5, the swing arm 6 and the grinding head 7, so that the grinding head 7 fits the surface of the workpiec...

Embodiment 2

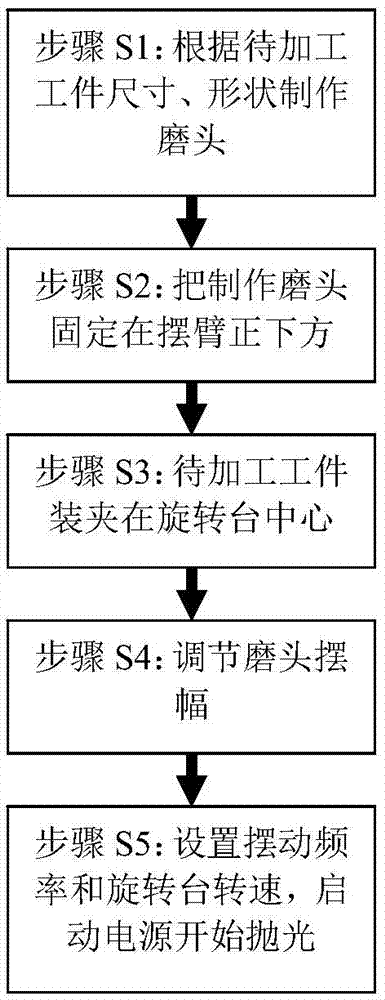

[0025] Embodiment two: combine figure 1 Describe this embodiment, this embodiment is realized through the following steps:

[0026] Step S1: making a polishing grinding head according to the shape of the workpiece to be processed. On the one hand, the polishing grinding head has a multi-layer structure, including a base layer, a flexible layer and a polishing layer, and the shape of the prepared polishing grinding head is consistent with the shape of the workpiece to be processed; On the one hand, the height of the grinding head should ensure that the radius of the swing arc is consistent with the radius of the shape of the workpiece to be processed. After assembly, the polished grinding head should be fixed directly under the swing arm;

[0027] Step S2: Clamp the workpiece so that the workpiece to be processed is clamped on the rotary table, and the center of the workpiece to be processed is required to be consistent with the center of the rotary table, and the eccentric err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com