Aluminum silicon carbide pouring material

A technology of aluminum silicon carbide and castables, which is applied in the field of castables, can solve problems such as not being able to meet the needs, and achieve the effects of high compressive strength, short curing time and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

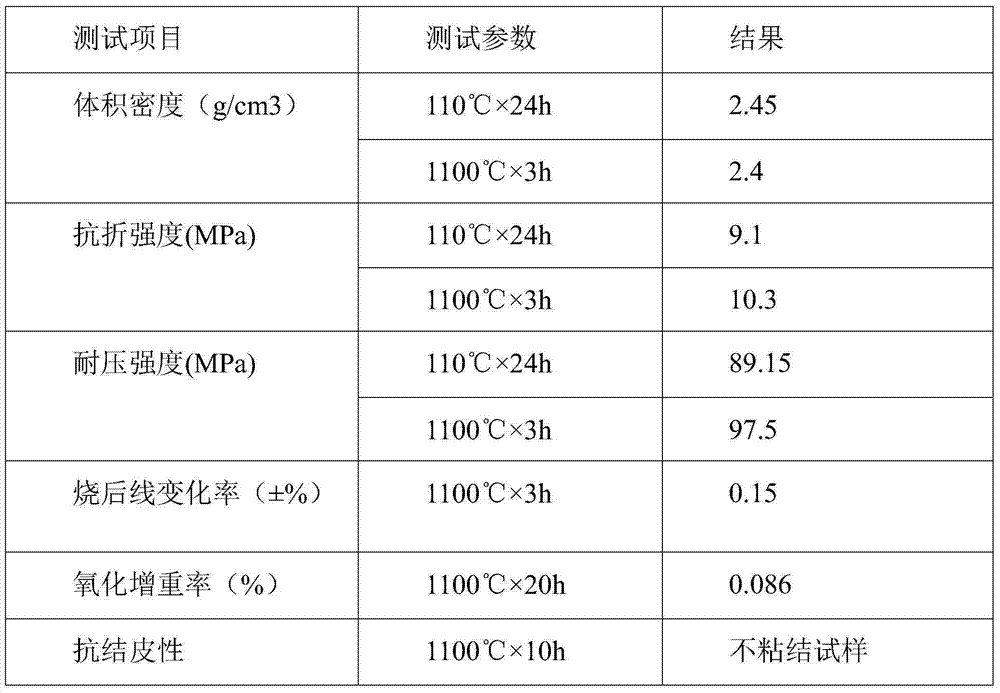

Embodiment 1

[0018] A kind of aluminum silicon carbide castable, its component comprises as follows by weight part:

[0019] Aggregate, which includes 7 parts of silicon carbide with a particle size of less than 1 mm, 12 parts of silicon carbide with a particle size of 1-4 mm, 10 parts of electric power industrial ceramics with a particle size of less than 1 mm, and 9 parts of electric power industrial ceramics with a particle size of 1-4 mm 10 parts of power industrial ceramics with a particle size of less than 8 mm;

[0020] Fine powder, which includes 10 parts of electric porcelain machining ball mill powder with a particle size of less than 0.088 mm, 8 parts of silicon carbide fine powder with a particle size of less than 0.064 mm, 4 parts of alumina fine powder with a particle size of less than 2 μm, and 3 parts of silicon micropowder with a particle size of less than 1 μm parts, CA-50-N cement 9 parts;

[0021] Binder, which includes 3 parts of silicon fine powder with a particle si...

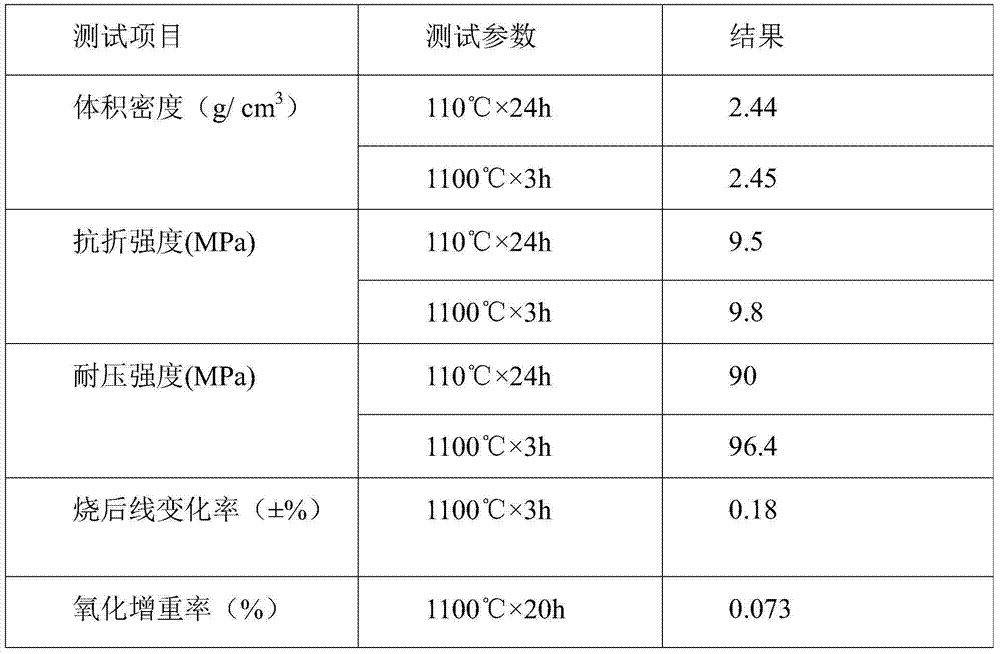

Embodiment 2

[0029] A kind of aluminum silicon carbide castable, its component comprises as follows by weight part:

[0030] Aggregate, which includes 12 parts of silicon carbide with a particle size of less than 1 mm, 16 parts of silicon carbide with a particle size of 1-4 mm, 15 parts of power industry ceramics with a particle size of less than 1 mm, and 15 parts of power industry ceramics with a particle size of 1-4 mm 17 parts of electric power industrial ceramics with a particle size of 4-8 mm;

[0031] Fine powder, which includes 15 parts of ball mill powder for electric porcelain processing with a particle size of less than 0.082 mm, 10 parts of silicon carbide fine powder with a particle size of less than 0.057 mm, 2 parts of alumina fine powder with a particle size of less than 1.5 μm, and silicon micropowder with a particle size of less than 1 μm 5 parts, 6 parts of CA-50-N cement;

[0032] Binder, which includes 5 parts of silica fine powder with a particle size of less than 0....

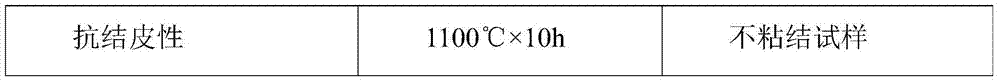

Embodiment 3

[0040] A kind of aluminum silicon carbide castable, its component comprises as follows by weight part:

[0041] Aggregate, which includes 12 parts of silicon carbide with a particle size of less than 1 mm, 12 parts of silicon carbide with a particle size of 1-4 mm, 15 parts of electric power industrial ceramics with a particle size of less than 1 mm, and 9 parts of electric power industrial ceramics with a particle size of 1-4 mm 17 parts of electric power industrial ceramics with a particle size of 4-8 mm;

[0042] Fine powder, which includes 10 parts of electromagnetic processing ball mill powder with a particle size of less than 0.088 mm, 10 parts of silicon carbide fine powder with a particle size of less than 0.064 mm, 2 parts of alumina fine powder with a particle size of less than 2 μm, and 4 parts of silicon micropowder with a particle size of less than 1 μm parts, 8 parts of CA-50-N cement;

[0043] Binder, which includes 4 parts of silica powder with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com