High-temperature-resisting steel cord conveyor belt glue and preparation method thereof

A technology for steel wire rope core and conveyor belt, applied in the field of high temperature resistant steel wire rope core conveyor belt adhesive and its preparation, can solve the problems of EPDM self-adhesion and poor mutual adhesion, and achieve high adhesion strength and high adhesion strength retention rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

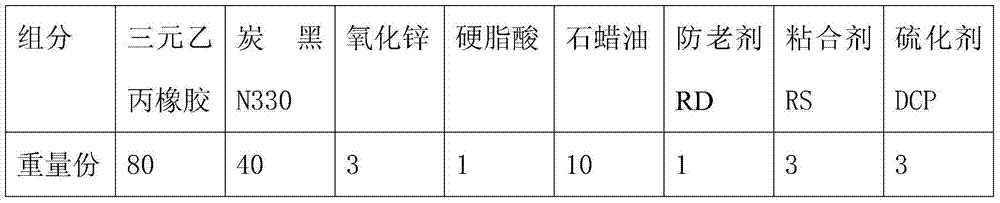

[0021] High-temperature-resistant steel cord conveyor belt adhesive compound formula of the present invention:

[0022]

[0023] The components of the above formula are mixed on an open mill according to the conventional process, and the obtained mixed rubber is vulcanized on a flat vulcanizer, and the condition of the vulcanization is 160 ° C × (t 90 +3min).

[0024] Test the tensile strength (MPa), elongation at break (%) and adhesive strength before and after aging (kN / m) of the obtained high-temperature-resistant steel cord conveyor belt adhesive. standard; the results are as follows:

[0025] Tensile strength: 17.5MPa;

[0026] Elongation at break: 415%

[0027] Adhesive strength before aging: 146kN / m;

[0028] Adhesive strength after aging: 156kN / m.

[0029] From the above results, it can be seen that the bonding strength between the adhesive and the steel wire rope is relatively high, and the retention rate of the bonding strength after hot air aging is high.

Embodiment 2

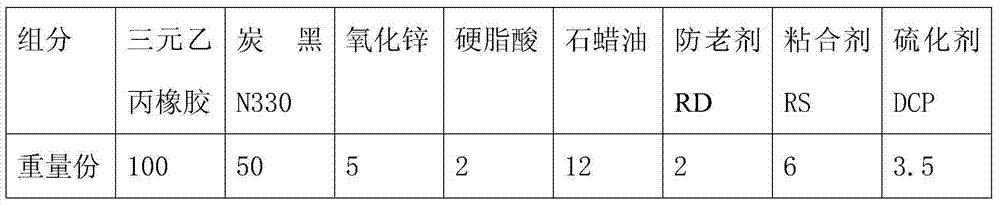

[0031] High-temperature-resistant steel cord conveyor belt adhesive compound formula of the present invention:

[0032]

[0033] The components of the above formula are mixed on an open mill according to the conventional process, and the obtained mixed rubber is vulcanized on a flat vulcanizer, and the condition of the vulcanization is 160 ° C × (t 90 +3min).

[0034] Test the tensile strength (MPa), elongation at break (%) and adhesive strength before and after aging (kN / m) of the obtained high-temperature-resistant steel cord conveyor belt adhesive. standard; the results are as follows:

[0035] Tensile strength: 18.6MPa;

[0036] Elongation at break: 400%

[0037] Adhesive strength before aging: 158kN / m;

[0038] Adhesive strength after aging: 162kN / m.

[0039] From the above results, it can be seen that the bonding strength between the adhesive and the steel wire rope is relatively high, and the retention rate of the bonding strength after hot air aging is high.

Embodiment 3

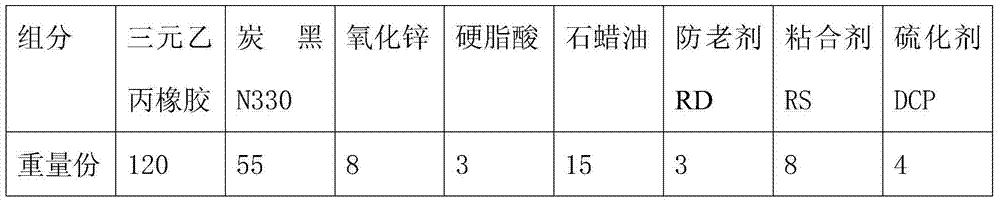

[0041] High-temperature-resistant steel cord conveyor belt adhesive compound formula of the present invention:

[0042]

[0043] The components of the above formula are mixed on an open mill according to the conventional process, and the obtained mixed rubber is vulcanized on a flat vulcanizer, and the condition of the vulcanization is 160 ° C × (t 90 +3min).

[0044] Test the tensile strength (MPa), elongation at break (%) and adhesive strength before and after aging (kN / m) of the obtained high-temperature-resistant steel cord conveyor belt adhesive. standard; the results are as follows:

[0045] Tensile strength: 17.9MPa;

[0046] Elongation at break: 385%

[0047] Adhesive strength before aging: 162kN / m;

[0048] Adhesive strength after aging: 166kN / m.

[0049] From the above results, it can be seen that the bonding strength between the adhesive and the steel wire rope is relatively high, and the retention rate of the bonding strength after hot air aging is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com