High-strength seamless steel tube for geological drilling and preparation method thereof

A technology of geological drilling and seamless steel pipes, which is applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of low plasticity index, achieve the effects of improving strength, improving energy use efficiency, and reducing alloy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

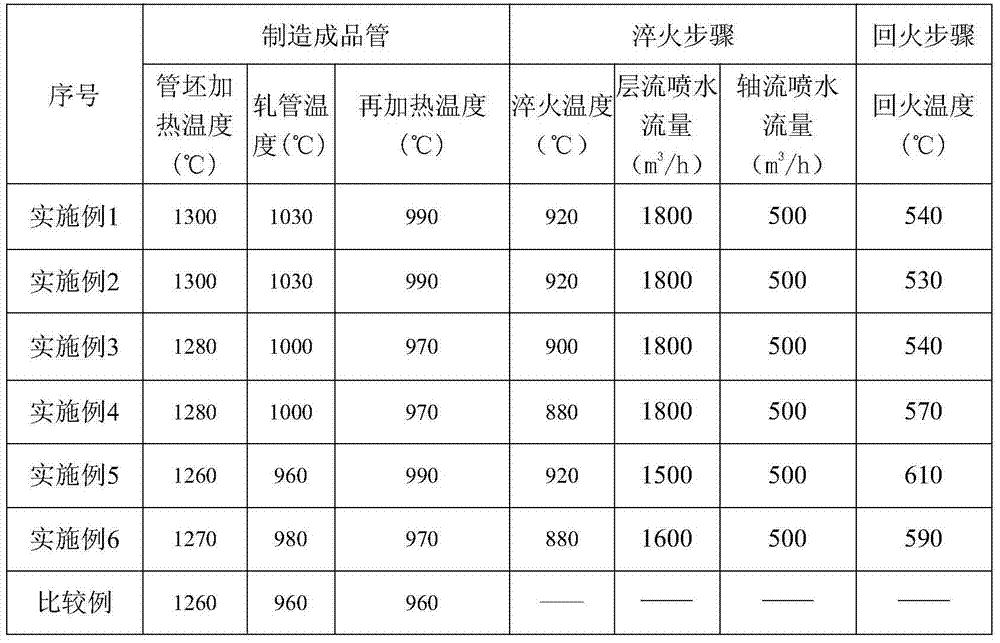

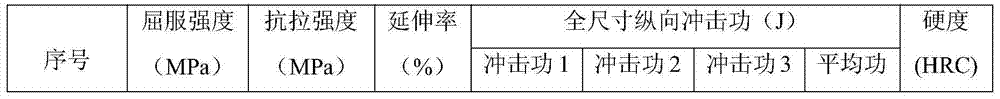

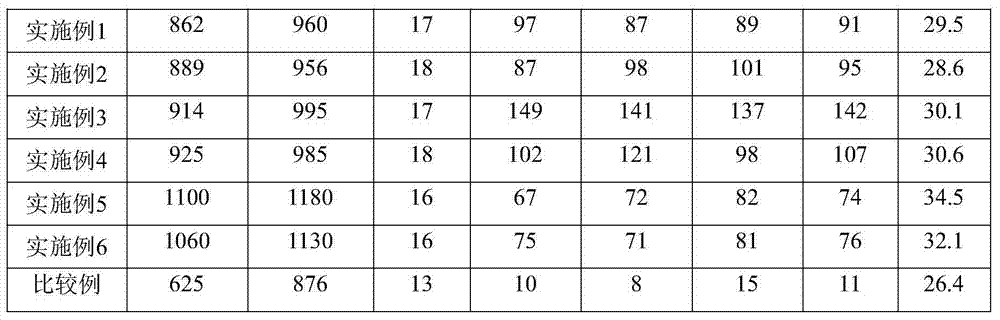

[0047] The high-strength seamless steel pipe for geological drilling according to the present invention and its manufacturing method will be further described below based on specific examples, but the specific examples and related descriptions do not constitute improper limitations to the technical solution of the present invention.

[0048] Embodiment 1~6 and comparative example

[0049] The high-strength geological drilling seamless steel pipe of the present invention is produced according to the following steps:

[0050] 1) Smelting: smelting and controlling the proportion of each chemical element as shown in Table 1;

[0051] 2) Billet making: direct continuous casting of molten steel into round tube billets;

[0052] 3) Manufacture of finished tube: heat the round tube billet to 1250-1300°C in the annular heating furnace, roll the tube at 950-1050°C after piercing through the piercing machine, and heat the rolled steel tube into the reheating furnace to 950-1000°C And k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com