Piston reciprocating internal combustion engine cylinder piston working environment enhancement system

A working environment and internal combustion engine technology, applied in the direction of machines/engines, pistons, engine components, etc., can solve problems such as increased wear, increased unfavorable factors, and damage to the roll force of the thermal load system of the engine cylinder piston group, to reduce friction, The effect of eliminating unfavorable factors and eliminating the hazards of system roll force and piston group thermal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

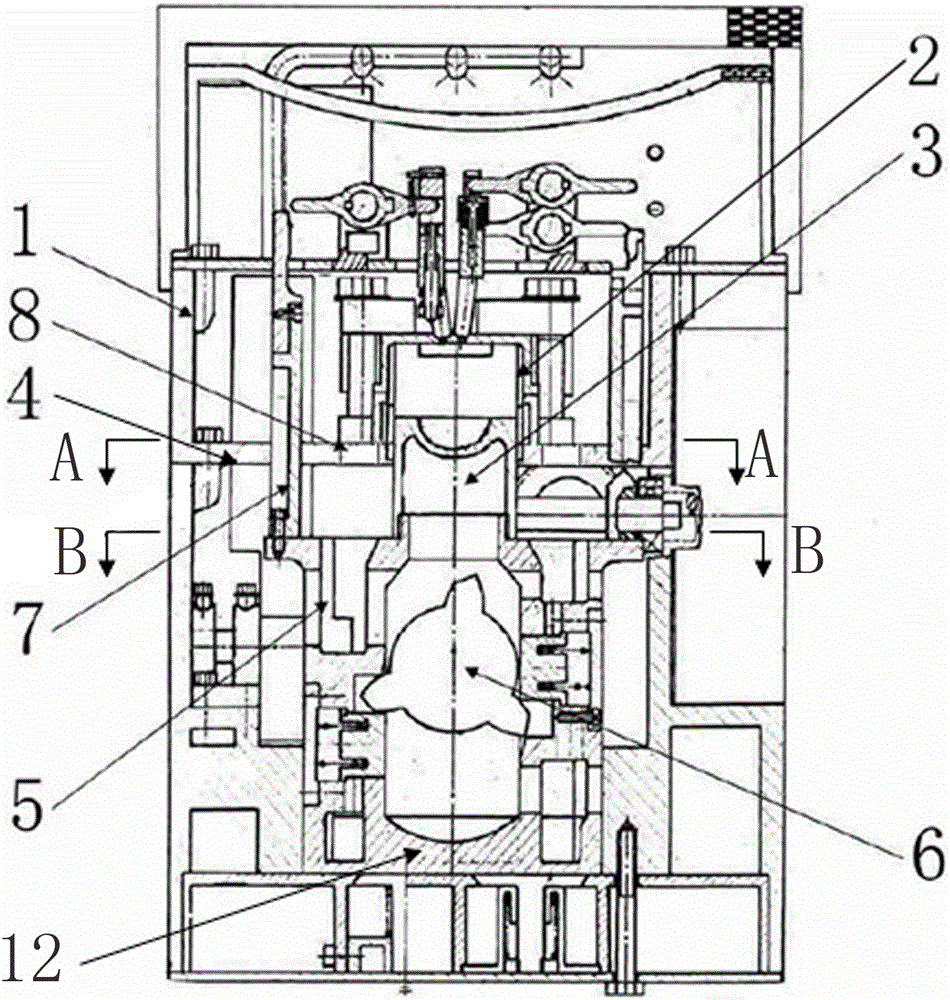

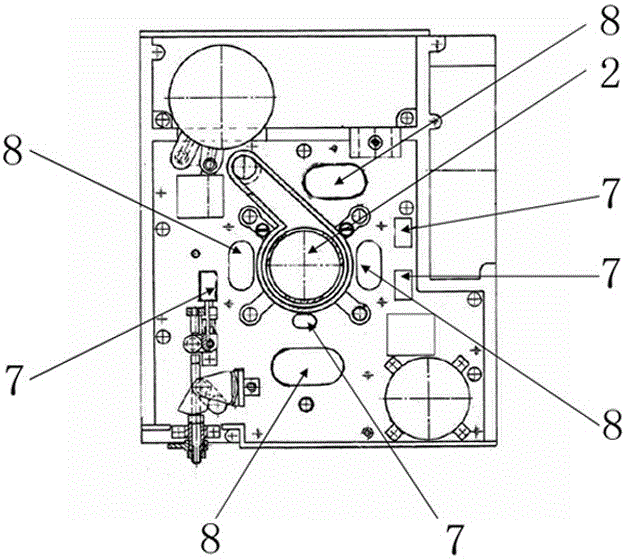

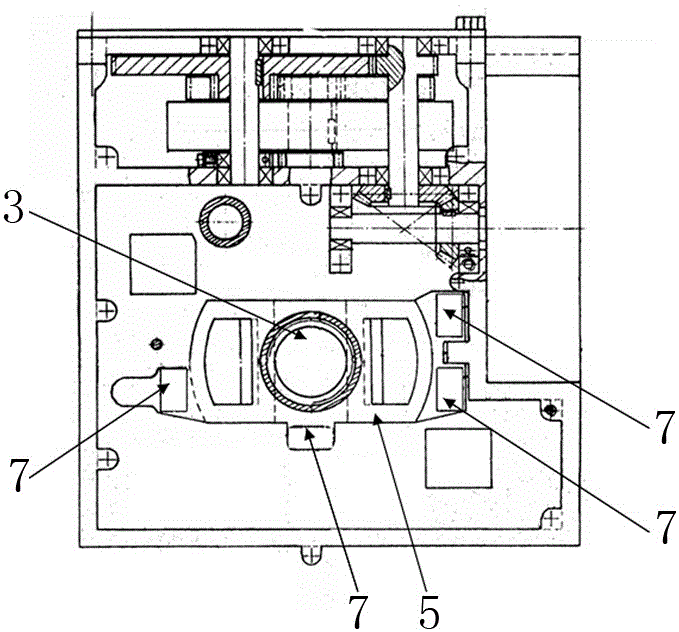

[0021] see Figure 1 to Figure 5, a new type of piston reciprocating internal combustion engine piston average speed strengthening device of the present invention, comprising the power mechanism of the internal combustion engine and the engine cylinder 2 arranged above the power mechanism, the engine cylinder 2 is fixedly connected with the transverse diaphragm 4 at the bottom of the upper body 1, the described The power mechanism is a rack and pinion mechanism, two parallel racks in the rack and pinion mechanism are connected horizontally at both ends to form a booster frame 5, and the upper end of the booster frame 5 is fixedly equipped with "secondary engine cylinder water spray", " The tappet 7 and the engine cylinder piston 3 of the working mechanisms such as "fuel and water liquid output pump", "fuel pump injection" and "e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com