Calibration method and device for three-optical-axis return and air bath linear displacement laser interferometer

A laser interferometer and laser interferometry technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problem of large Abbe errors and the inability to determine whether the interference mirror group and the measuring mirror belong to the standard laser interferometer components or are calibrated , Inaccurate calibration measurement results and other problems, to achieve the effect of small Abbe error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

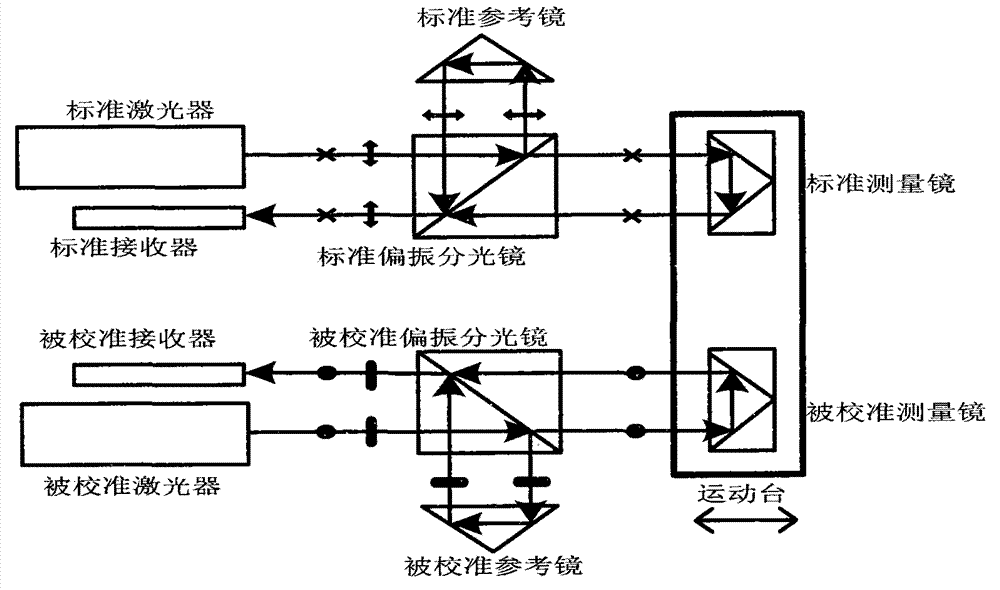

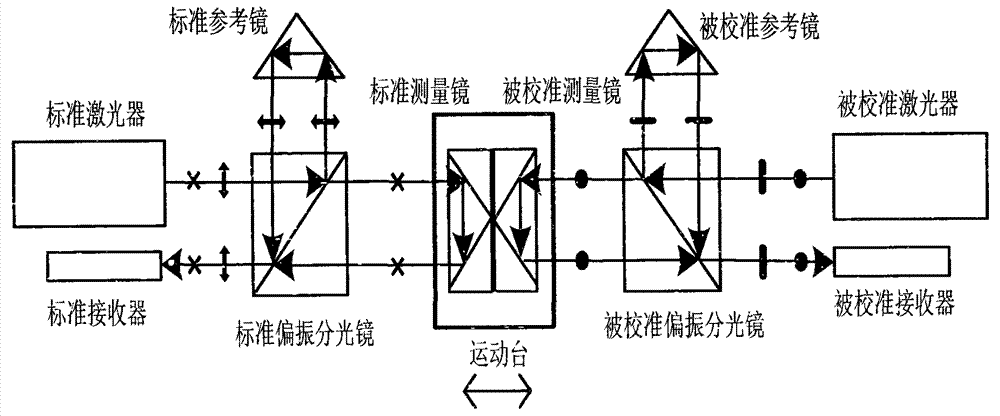

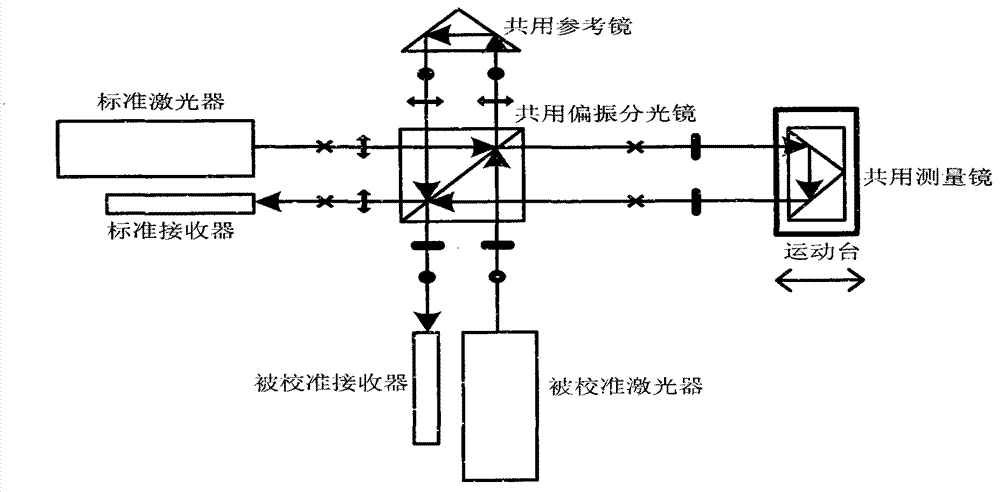

[0030] A three optical axis return and air bath linear displacement laser interferometer calibration device, including a standard laser interferometer laser 1, three receivers 7, 8, 9 arranged at positions capable of receiving interference signals from the standard laser interferometer, and wires The three receivers 7, 8, 9 are respectively connected to the standard laser interferometer signal processing system 10; on the output optical path of the standard laser interferometer laser 1, an intermediate through hole 14 is arranged to allow the calibrated laser interferometer measurement beam 13 to pass through The passed three-axis hollow standard laser interference mirror group 2; the guide rail 20 is arranged on one side of the three-axis hollow standard laser interference mirror group 2, and the moving table 19 is fitted on the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com