A Calibration Method for Distortion of f‑θ Optical System

A technology of optical system and testing method, which is applied in the direction of optical instrument testing, testing of optical performance, testing of machine/structural components, etc. It can solve problems such as errors in processing and assembly, low measurement accuracy, and complicated target production, and achieve work efficiency. The effect of high and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

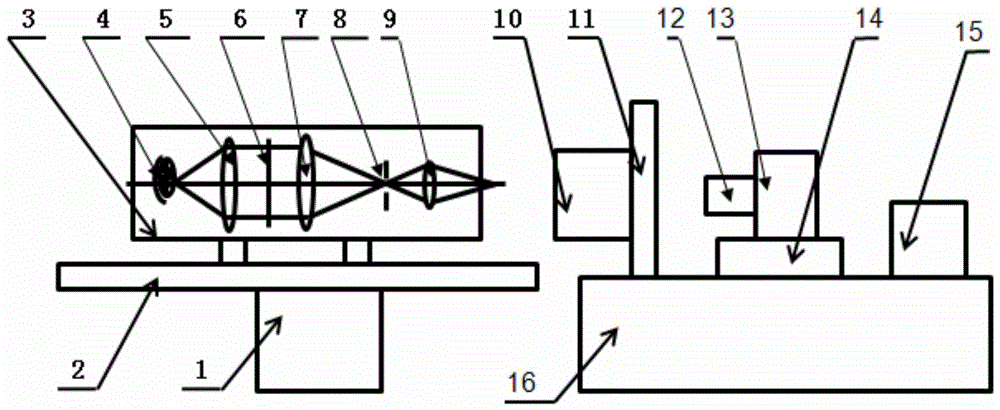

[0030] The present invention is a kind of distortion testing device of f-theta optical system, including turntable 1, long guide rail 2, composed of light source 4, collimator mirror 5, optical filter 6, condenser mirror 7, star hole plate 8, target miniature mirror 9 Target generator, special tooling 11, image analyzer made up of imaging objective lens 12, detector 13, three-dimensional mobile support 14, computer 15, platform 16, computer 15 includes automatic control software, calculation processing software; target generator setting On the object side of the calibrated optical system, the image analyzer is set on the image side of the calibrated optical system, and the moving parts are connected with the computer, and their movement is controlled by automatic control software.

[0031] The function of the turntable 1 is to drive the target generator to rotate, and provide the target of the off-axis field of view for the f-θ optical system, which can be an electronically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com