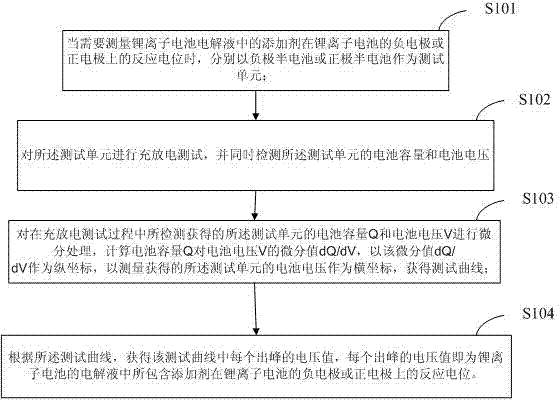

Method for determining reaction potential of additive in lithium-ion cell electrolyte

A lithium-ion battery and electrolyte technology, applied in the direction of material electrochemical variables, AC/pulse peak measurement, etc., can solve the problem that the scan rate cannot correspond to the current, the data cannot play a correct guiding role, and the scan rate has a great influence, etc. Problems, to achieve significant production practice significance, enhance product use experience, and ensure the effect of work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

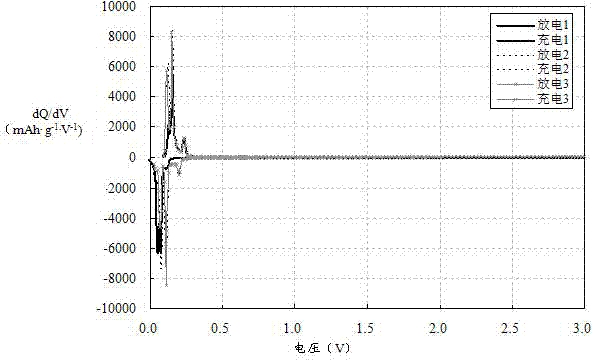

[0043] For the first battery system, in order to optimize the current and voltage process when the battery is formed for the first time, it is first necessary to investigate the film-forming reaction potential of the electrolyte additive on the negative electrode, so as to provide a reference for the charging cut-off voltage setting during the effective battery formation. First, the negative electrode active material of the first battery system is used to prepare the negative electrode sheet. The preparation process of the negative electrode sheet must be the same as that of the pole piece of the effective battery, or directly select the single-side coated part of the pole piece of the effective battery as the working electrode. In this example, a CR2430 button battery is used as the test unit of the first battery system. The single negative electrode of the first battery system is used as the working electrode, the lithium sheet is used as the counter electrode, and the button ...

Embodiment 2

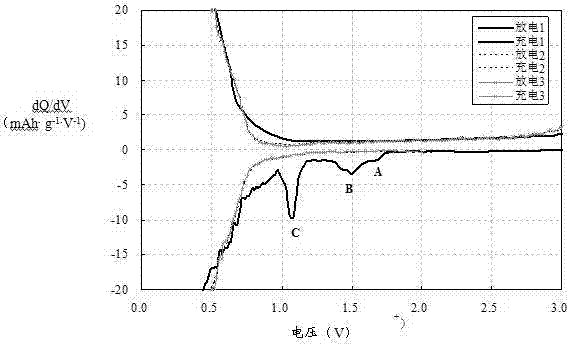

[0045] For the second battery system, in order to optimize the current and voltage process when the battery is formed for the first time, it is first necessary to investigate the film-forming reaction potential of the electrolyte additive on the negative electrode, so as to provide a reference for the charging cut-off voltage setting during the effective battery formation. The same method as in Example 1 was used to make a button battery as the test unit of the second battery system. According to the quality of the working electrode and the ratio of the slurry, the theoretical capacity was calculated to be 4.81 mAh, and it was charged and discharged with blue electric equipment. The current is set to 0.20 mA, that is, the current rate is 0.2 mA / 4.81 mAh = 0.04 C, the discharge cut-off voltage is set to 0.005 V, and the charge cut-off voltage is set to 3.0 V. The charge and discharge capacity and voltage data in the previous three cycle data are taken, Calculate the differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com