Dry etching lower electrode and dry etching device

A dry etching and electrode technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of easy generation of bad spots, poor cooling effect in the contact area, affecting the quality of the process, etc., to prevent the high incidence of bad spots and enhance adsorption. ability, the effect of improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The dry etching lower electrode and the dry etching device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

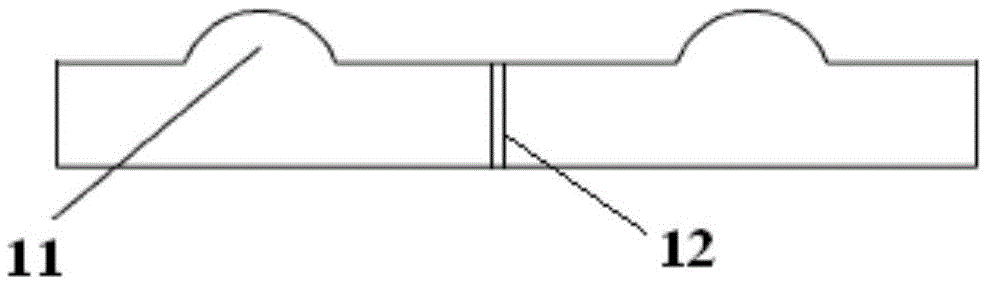

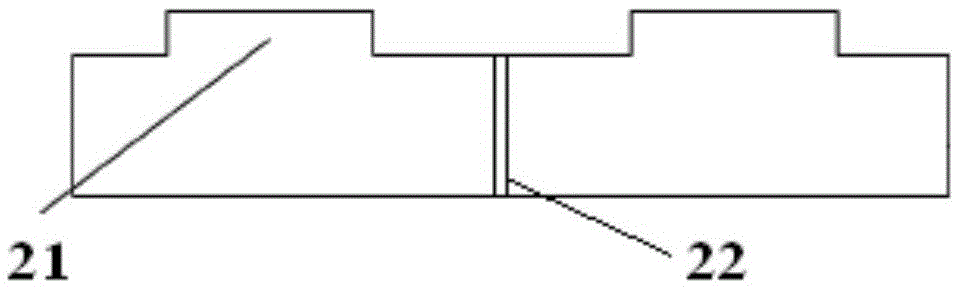

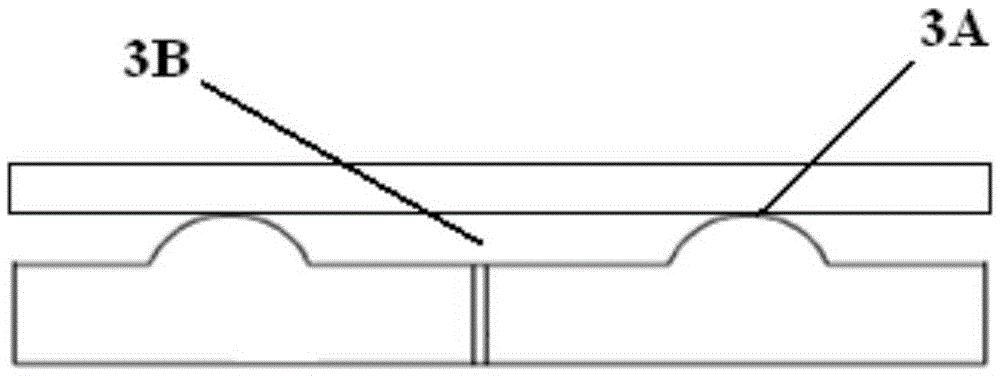

[0025] Figure 4 A schematic diagram of the structure of the dry-etched lower electrode provided by the embodiment of the present invention, Figure 4 The figure in the upper circle is a partially enlarged schematic diagram of part A of the lower part. Such as Figure 4 As shown, the embodiment of the present invention provides a dry-etched lower electrode, which includes a plate-shaped electrode plate 31 , and an insulating layer 32 is provided on the electrode plate 31 . The insulating layer 32 has an uneven rough surface 33 .

[0026] The embodiment of the present invention provides a dry etching lower electrode and a dry etching device. Compared with the existing dry etching lower electrode, the insulating layer in the dry etching lower electrode provided by the embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com