Kelp-flavored food ingredient and preparation method thereof

A technology for food ingredients and kelp flavor, applied in food preparation, bacteria used in food preparation, food drying, etc., can solve problems such as poor functionality and poor absorption of nutrients

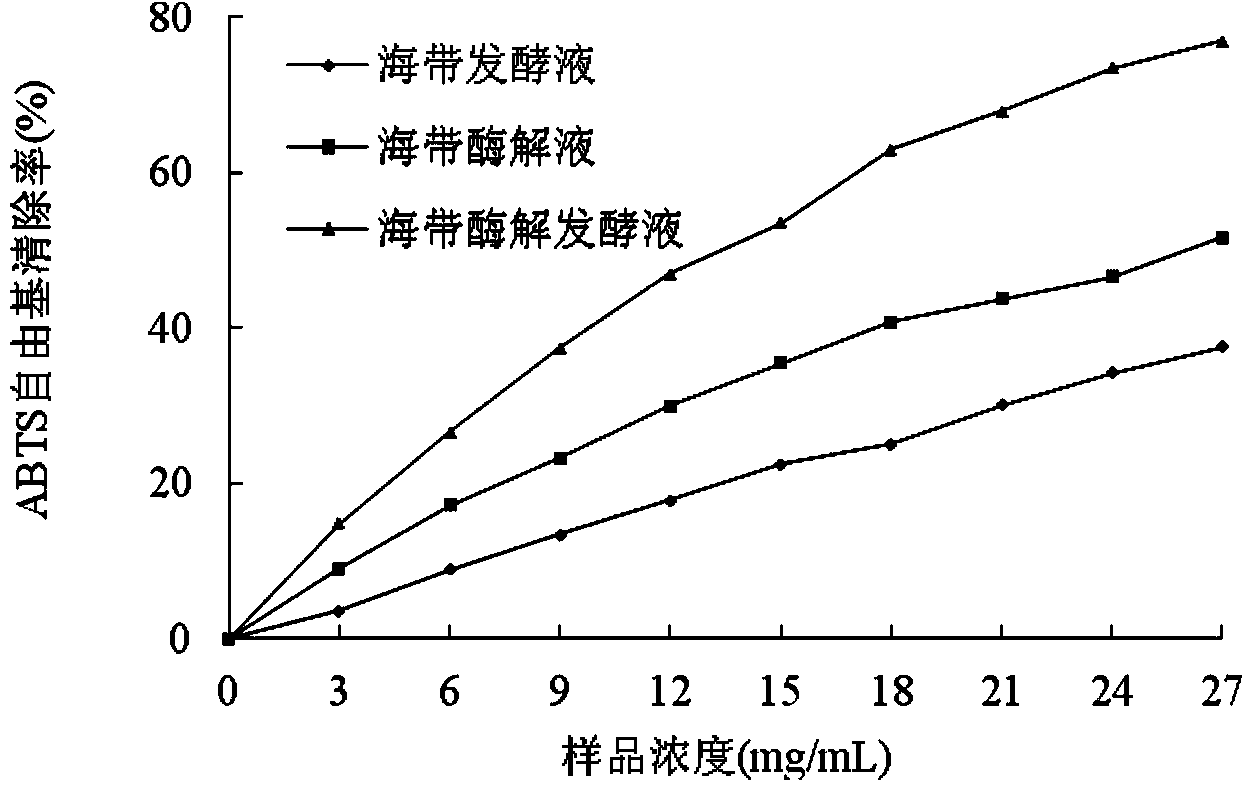

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

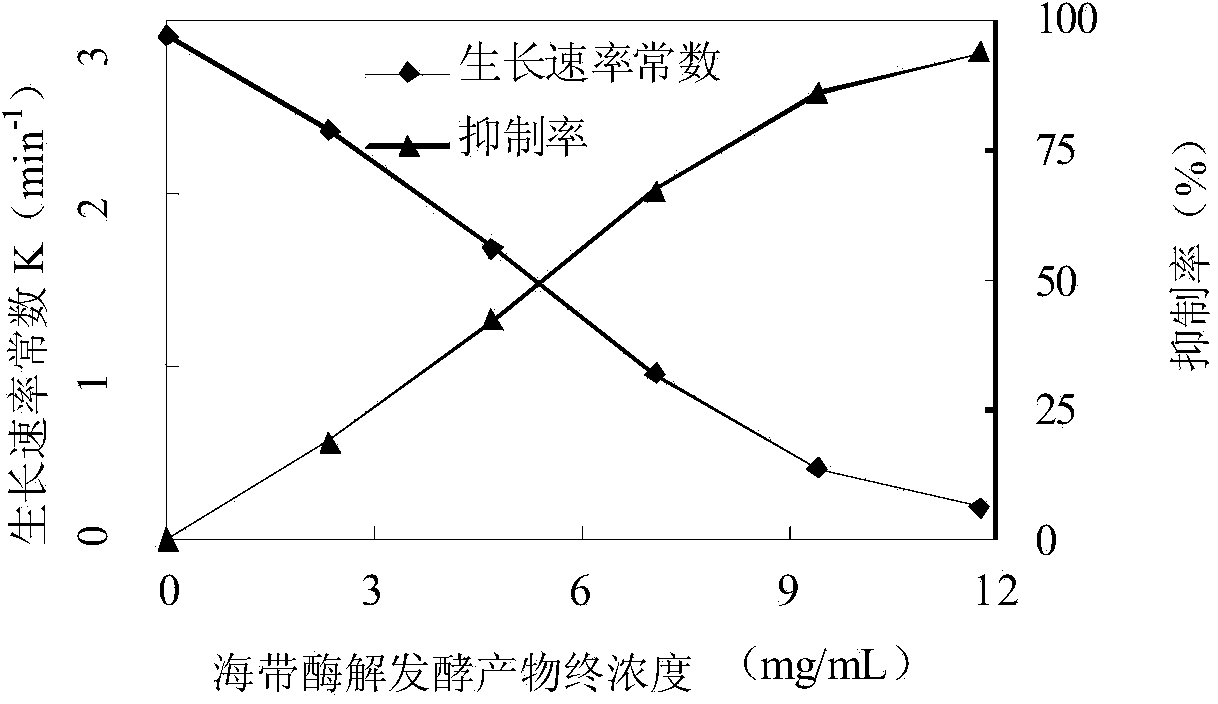

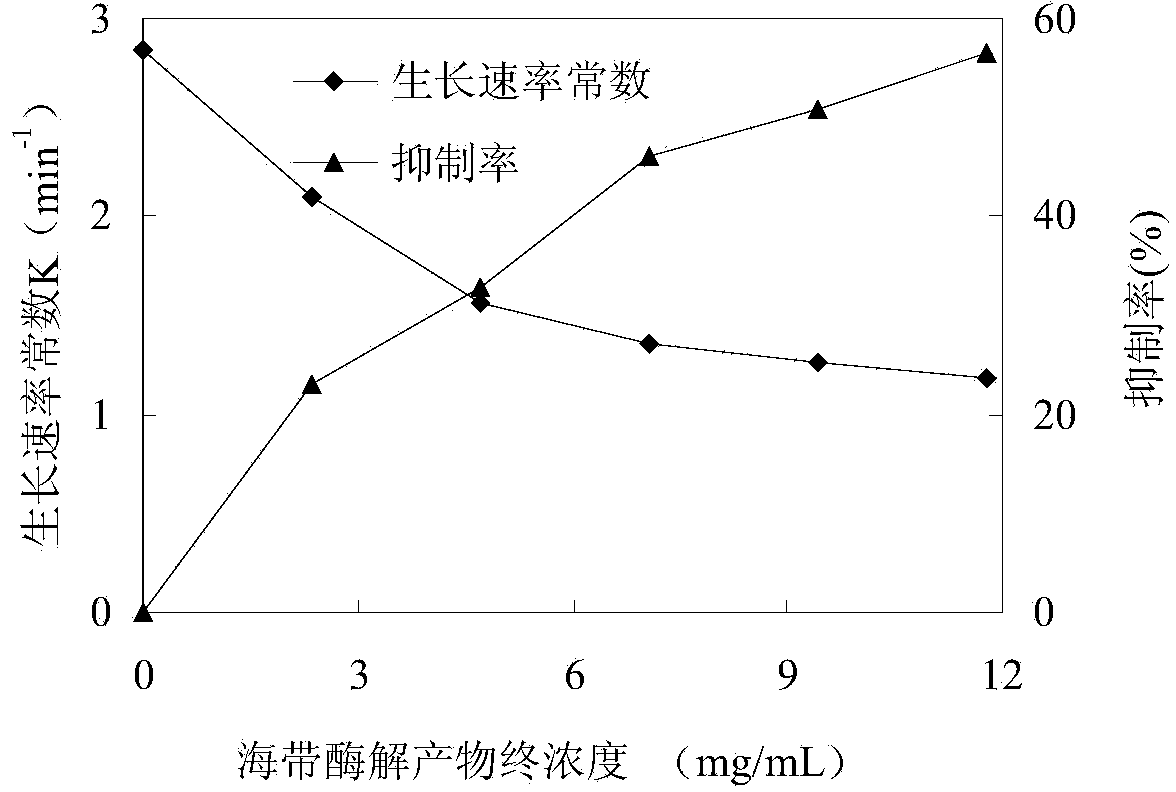

Examples

Embodiment 1

[0043] Embodiment 1, preparation seaweed flavor food batching

[0044] Both Corynebacterium glutamicum and Pediococcus pentosacea can be purchased commercially, and the bacterial strains used in the present invention are all purchased from China Industrial Microorganism Culture Collection and Management Center. . Cellulase, pectinase, and papain are also commercially available.

[0045] 1. Preparation of Corynebacterium glutamicum bacteria liquid: Inoculate Corynebacterium glutamicum into the seed medium from the slant plate (the composition of the seed medium is: peptone 10g / L, yeast extract 10g / L, propanesulfonic acid (MOPS) 42g / L, glucose 20g / L, pH7.4 aqueous solution), cultivated at 30°C and 200rpm for 12 hours to obtain the primary seed liquid, and then transferred the primary seed liquid to fresh seed medium, 30°C 1. Cultivate for 8 hours under the condition of 200rpm to obtain the secondary seed liquid of Corynebacterium glutamicum, that is, the liquid of Corynebacter...

Embodiment 2

[0059] Embodiment 2, preparation kelp flavor food batching

[0060] Step 1 and Step 2 are the same as in Example 1.

[0061] 3. The present embodiment prepares seaweed flavor food ingredients, including the following operations:

[0062] 1) Raw material pretreatment:

[0063] Adopting the dried kelp, removing impurities and dust, pulverizing it to 60-120 mesh (preferably 100 mesh) to obtain dry kelp powder;

[0064] 2) Enzymolysis:

[0065] Take 240g of dried kelp powder, put it into a 5L enzymolysis reaction kettle, add 2760mL of pure water (10-20 times of water), mix well to obtain dry kelp powder, heat up to 40°C (40-50°C is acceptable), adjust pH5.0 (5.0-6.0 is acceptable), then add compound enzyme (cellulase: pectinase: papain = 2:1:1, mass ratio), stir the enzymolysis for 6 hours (3-6 hours are acceptable) to obtain the enzymolysis solution;

[0066] 3) Fermentation:

[0067] Pour the enzymolysis solution (3L) after enzymolysis into a 5L fermenter, raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com