Gas mixing dilution device

A dilution device, gas mixing technology, applied in the direction of gas and gas/vapor mixing, mixer, mixing method, etc., can solve the problems of wear resistance, corrosion, poor acid and alkali resistance, etc., to avoid gas leakage, increase Precise, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

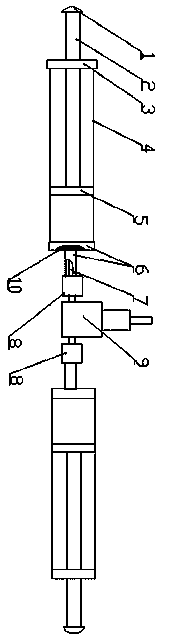

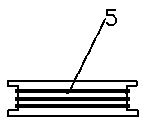

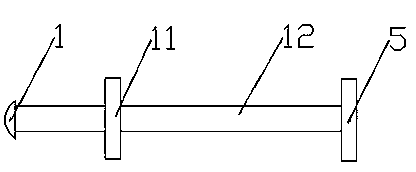

[0044] A gas mixing and dilution device, comprising an injection unit, the injection unit includes a syringe and a propulsion mechanism located in the syringe 4, a cap 3 located at the tail end of the syringe 4, and an injection port located on the bottom of the front end of the syringe 4 , the injection tube 7 that is connected with the injection port; the propulsion mechanism includes a push rod 2 that passes through the syringe 4 and enters the interior of the syringe 4, the end of the push rod 2 has a handle 1, and the front end of the push rod 2 has a piston 5, and the device also includes An annular snap ring 11, the outer wall of the annular snap ring 11 is engaged with the cylinder cap 3, and the inner wall of the annular snap ring 11 is engaged with the push rod 2; there are two ventilation holes on the snap ring 11, so that the push rod 2 can be taken out; of course It can also be one or more air holes, and the two air holes are symmetrically distributed in the center...

Embodiment 2

[0061] A gas mixing and dilution device, including an injection unit, the injection unit includes a syringe and a propulsion mechanism located in the syringe 4, and also includes a cap 3 located at the tail end of the syringe 4, and the front end of the syringe 4 has no bottom and is open shape, a sealing gasket 10 is clamped in the opening; the cylinder cap 3 is threadedly connected with the injection cylinder 4, and the cylinder cap 3 is made of stainless steel;

[0062] The sealing gasket 10 and the front end of the injection cylinder 4 are covered with a stainless steel connecting sleeve 6, and the center of the sealing gasket 10 has an injection port; the injection tube 7 is connected to the injection port; the propulsion mechanism includes passing through the injection cylinder 4 and entering the injection port. The push rod 2 inside the cylinder 4 has a handle 1 at the end of the push rod 2, and a piston 5 at the front end of the push rod 2. The device also includes an a...

Embodiment 3

[0100] The piston and the sealing gasket are made of the same material, and both include the following components in parts by weight:

[0101] Polypropylene 5 Polybutene 1

[0102] Polytetrafluoroethylene1 Octene-Ethylene Copolymer1

[0103] Bisphenol epoxy resin 2 PVC 10

[0104] Antiaging agent p-phenylenediamine 2.

[0105] The structure of the device is exactly the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com