Method for manufacturing silencer of split-type structure

A manufacturing method and technology of mufflers, which are applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of high welding temperature, large thermal influence of copper pipes, and increased process difficulty, so as to reduce environmental pollution. , The welding reliability is reduced, and the effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technology of the present invention will be described below with reference to specific embodiments.

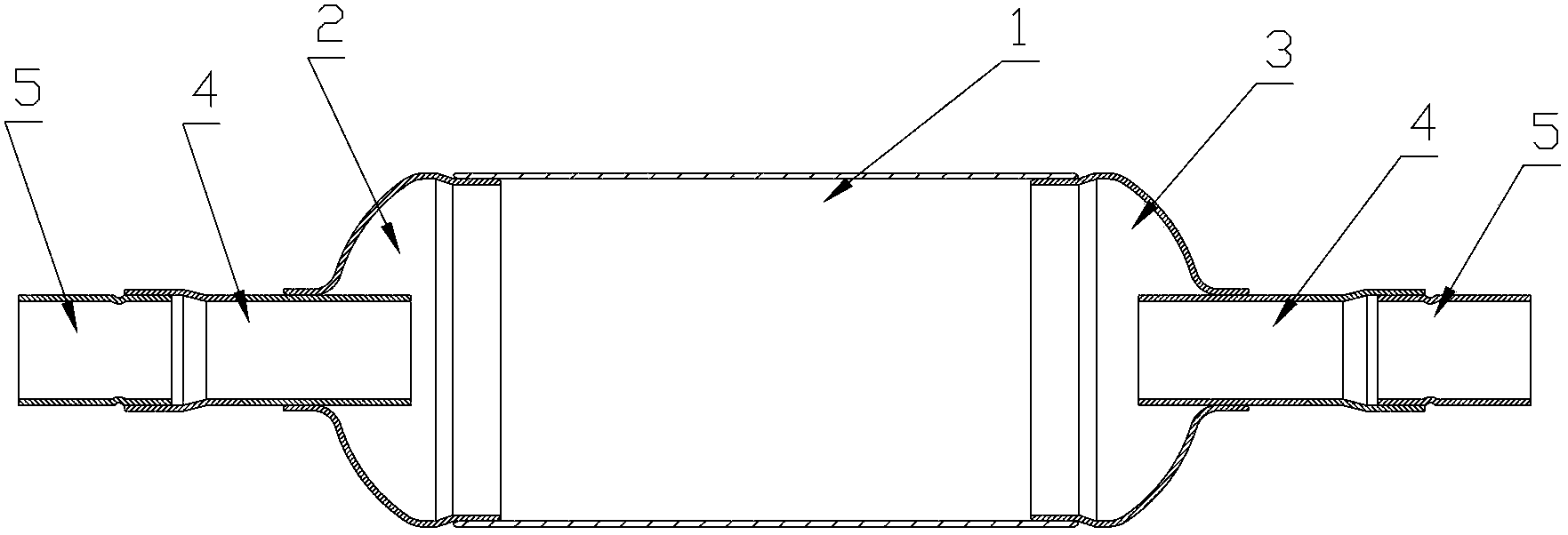

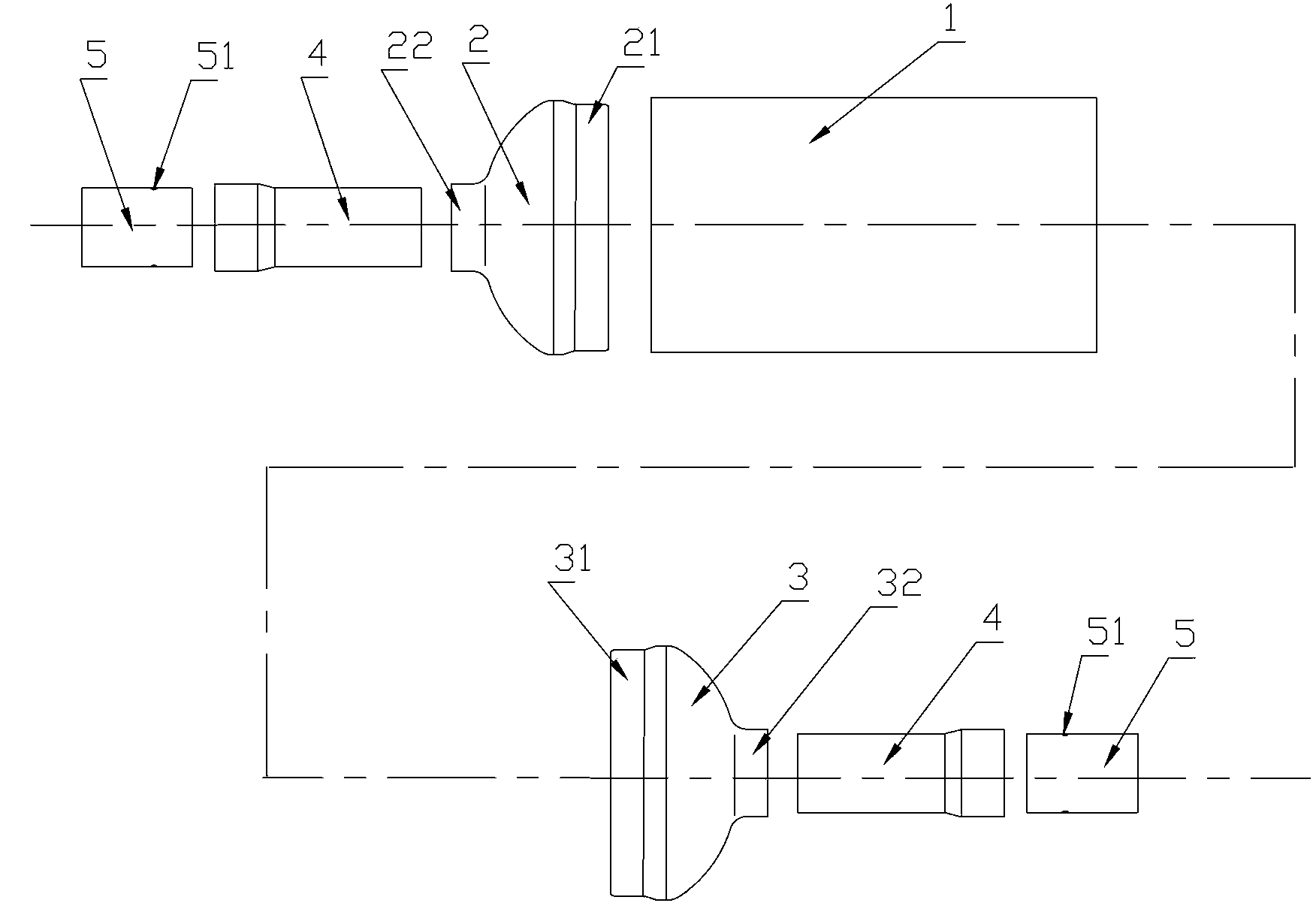

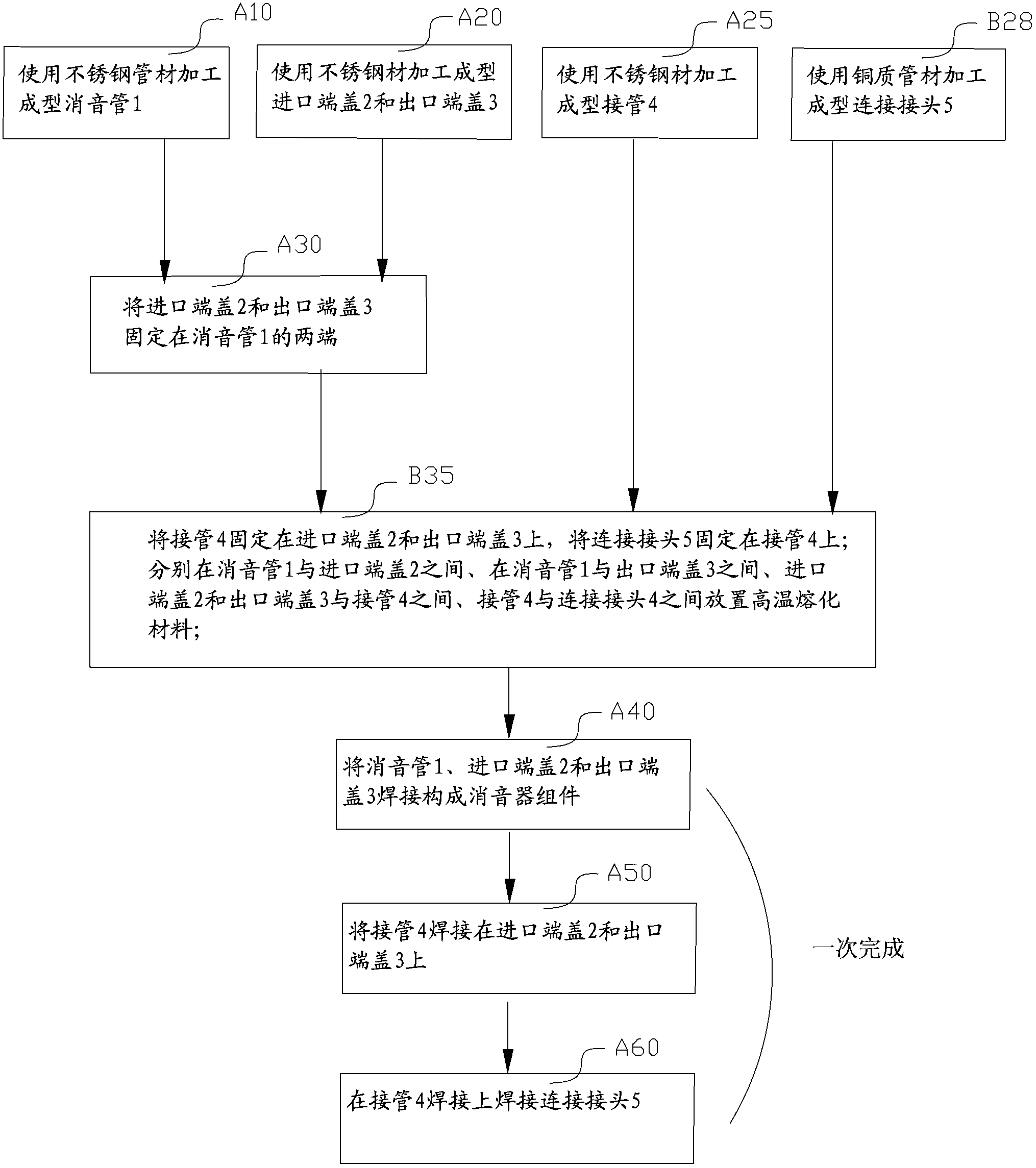

[0036] figure 1 The schematic diagram of the preferred split muffler structure given by the present invention; figure 2 for figure 1 The assembly diagram of each part of the split muffler shown in ; image 3 for figure 1 A schematic diagram of the preferred manufacturing process of the split muffler shown in .

[0037] like figure 1 , figure 2 and image 3 shown. The difference from the small muffler structure is that the split muffler has a cylindrical muffler tube 1, the inlet end cap 2 and the outlet end cap 3 are placed at both ends of the muffler tube 1, and the inlet end cap 2 and the outlet end cap 3. A connecting pipe 4 is also connected to the pipe 4, and a connecting joint 5 is connected to the connecting pipe 4.

[0038] The manufacturing method of the split muffler of this structure comprises the following steps:

[0039] A10: Using seaml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com