Fiber rope for food safety and manufacturing method thereof

A food safety and production method technology, applied in the rope field, can solve the problems of food pollution and low safety, and achieve the effect of high safety performance, reasonable process and excellent cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

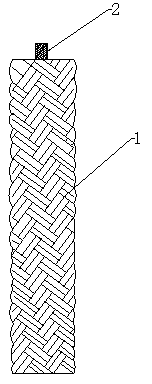

[0025] 1) Material selection: Rope sheath 1 selects modified polyether ether ketone fiber filament, its specification is 840 D, rope core 2 selects modified polyether ether ketone fiber filament, its specification is 1000 D; polyether ether ketone fiber filament The treatment process is: after drying the purified spinning grade polyetheretherketone resin, add 2% (WT%) heat stabilizer, 4% (WT%) inorganic nanomaterials and 2% (WT%) organic Polymer materials, and then made into modified polyetheretherketone spinning special materials, after drying, melted in the extruder and then entered into the melt metering pump, and then passed through the filter screen of the filter system and the porous spinneret to form modified polyetheretherketone Polyether ether ketone monofilament, after delayed cooling, oiling and bundling, the modified polyether ether ketone multifilament is obtained, and the modified polyether ether ketone fiber filament is obtained after heat stretching and shaping;...

Embodiment 2

[0032] 1) Material selection: Rope sheath 1 selects modified polyether ether ketone fiber filament, its specification is 1000 D, rope core 2 selects modified polyether ether ketone fiber filament, its specification is 1000 D; polyether ether ketone fiber filament The treatment process is: after drying the purified spinning grade polyetheretherketone resin, add 0.5% (WT%) heat stabilizer, 0.3% (WT%) inorganic nanomaterials and 4% (WT%) organic Polymer material, and then made into modified polyetheretherketone spinning special material, after drying, it is melted in the extruder and then enters the melt metering pump, and then passes through the filter screen of the filtration system and the porous spinneret to form modified polyetheretherketone. Polyether ether ketone monofilament, after delayed cooling, oiling and bundling, the modified polyether ether ketone multifilament is obtained, and the modified polyether ether ketone fiber filament is obtained after heat stretching and ...

Embodiment 3

[0039] 1) Material selection: Rope sheath 1 selects modified polyether ether ketone fiber filament, its specification is 3000 D, rope core 2 selects modified polyether ether ketone fiber filament, its specification is 1000 D; polyether ether ketone fiber filament The treatment process is: after drying the purified spinning grade polyetheretherketone resin, add 1% (WT%) heat stabilizer, 3% (WT%) inorganic nanomaterials and 0.6% (WT%) organic Polymer material, and then made into modified polyetheretherketone spinning special material, after drying, melted in the extruder, then enters the melt metering pump, and then passes through the filter screen of the filter system, the porous spinneret to form a modified polyetheretherketone Polyether ether ketone monofilament, after delayed cooling, oiling and bundling, the modified polyether ether ketone multifilament is obtained, and the modified polyether ether ketone fiber filament is obtained after heat stretching and shaping;

[0040...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap