Combined Oxidation Bed of Coal Mine Ventilation Air Preheating Catalytic Oxidation Device

A catalytic oxidation bed, catalytic oxidation technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of poor operation stability, low oxidation efficiency, and high light-off temperature, and achieve enhanced flow capacity and improved methane oxidation rate. , the effect of reducing the light-off temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

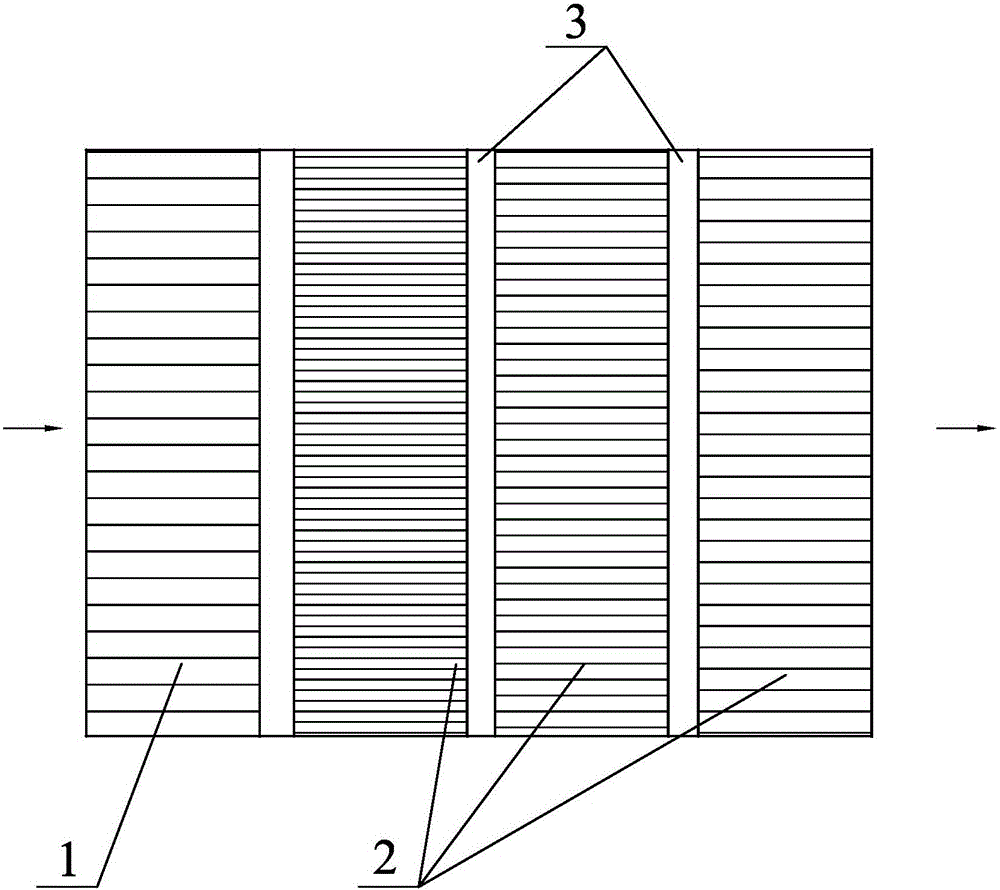

[0014] The present invention will be further described below in conjunction with the accompanying drawings. exist figure 1 In the shown embodiment: including the uniform temperature and uniform flow bed 1 and the catalytic oxidation bed arranged along the air flow direction, wherein the uniform temperature and uniform flow bed 1 is formed by stacking honeycomb ceramic regenerators, and along the air flow direction, the catalytic oxidation bed consists of 3 Composed of catalytic oxidation layers 2, each catalytic oxidation layer 2 is filled with a honeycomb catalyst, there is a gap 3 of 3 mm between adjacent catalytic oxidation layers 2, and the catalysts filled in the three catalytic oxidation layers 2 are arranged along the airflow direction. The active component loading, specific surface area and pore density all decrease stepwise, and the active component loading of catalysts filled with adjacent catalytic oxide layers 2 differs by 100g / m 3 , the specific surface area diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com