Microseismic monitoring analog system

A simulation system and microseismic technology, which is applied in the seismology of well logging records, etc., can solve the problems of rupture of the measured object, inability to simulate three-dimensional microseismic, and inability to use multiple times, and achieve the effect of accurate acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing, the present invention is described in further detail:

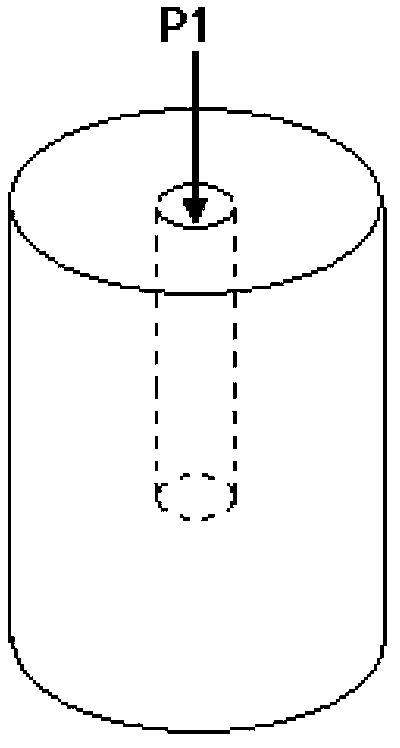

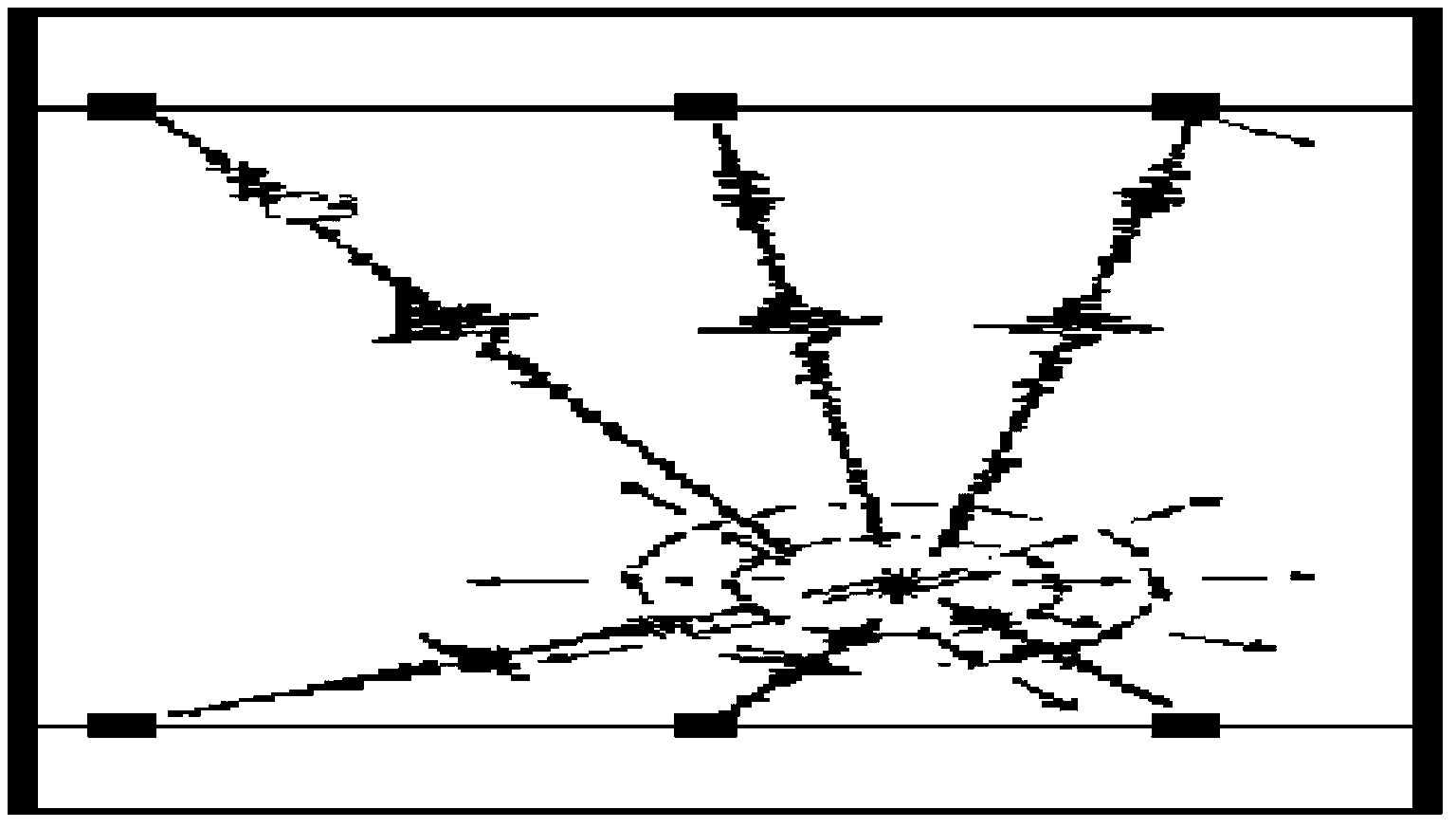

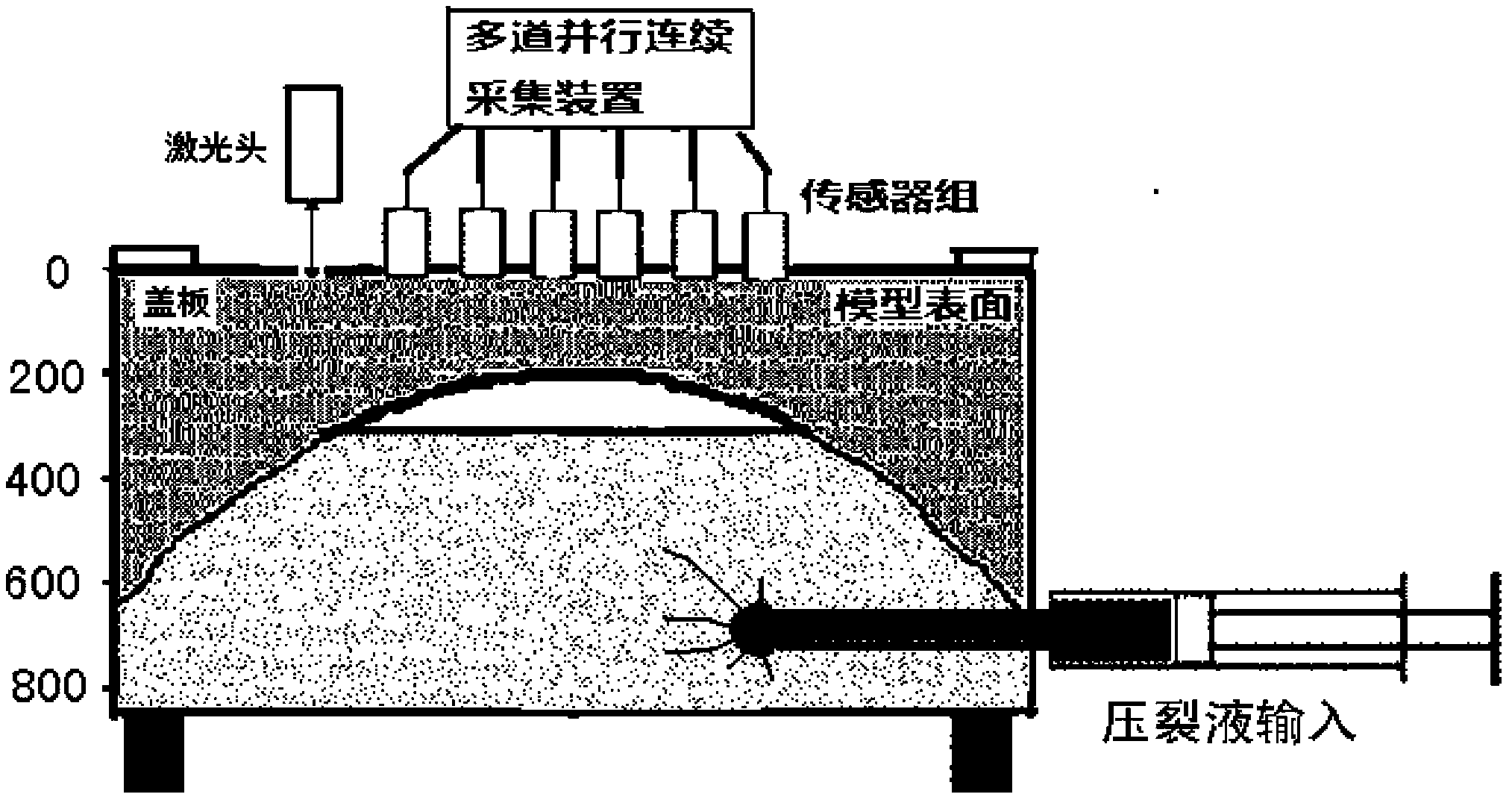

[0066] The principle diagram of the micro-seismic monitoring and simulation system of the present invention is as follows image 3 As shown, because the model is a cube or a cuboid with a square cross section, the sensors laid on the surface of the model should be laid on one surface, that is, there are multiple rows, but image 3 Only 6 sensors are given as an illustration, and various sensor arrangements such as 2x8 and 4x4 can be used for actual detection. The working process of the system is briefly described as follows: the fracturing fluid is pressurized and injected into the model under test, and the micro-seismic signal detection device is activated at the same time. When the pressure reaches the crack initiation pressure, a crack occurs. When a crack is generated, a micro-seismic sound wave signal is transmitted to the surroundings. The sensor group laid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com