Monochrome full-parallax holographic three-dimensional one-step printer light path structure

A full parallax, printer technology, applied in optics, optical components, instruments, etc., can solve the problems of high cost and high cost, and achieve the effect of process automation, easy portability and observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

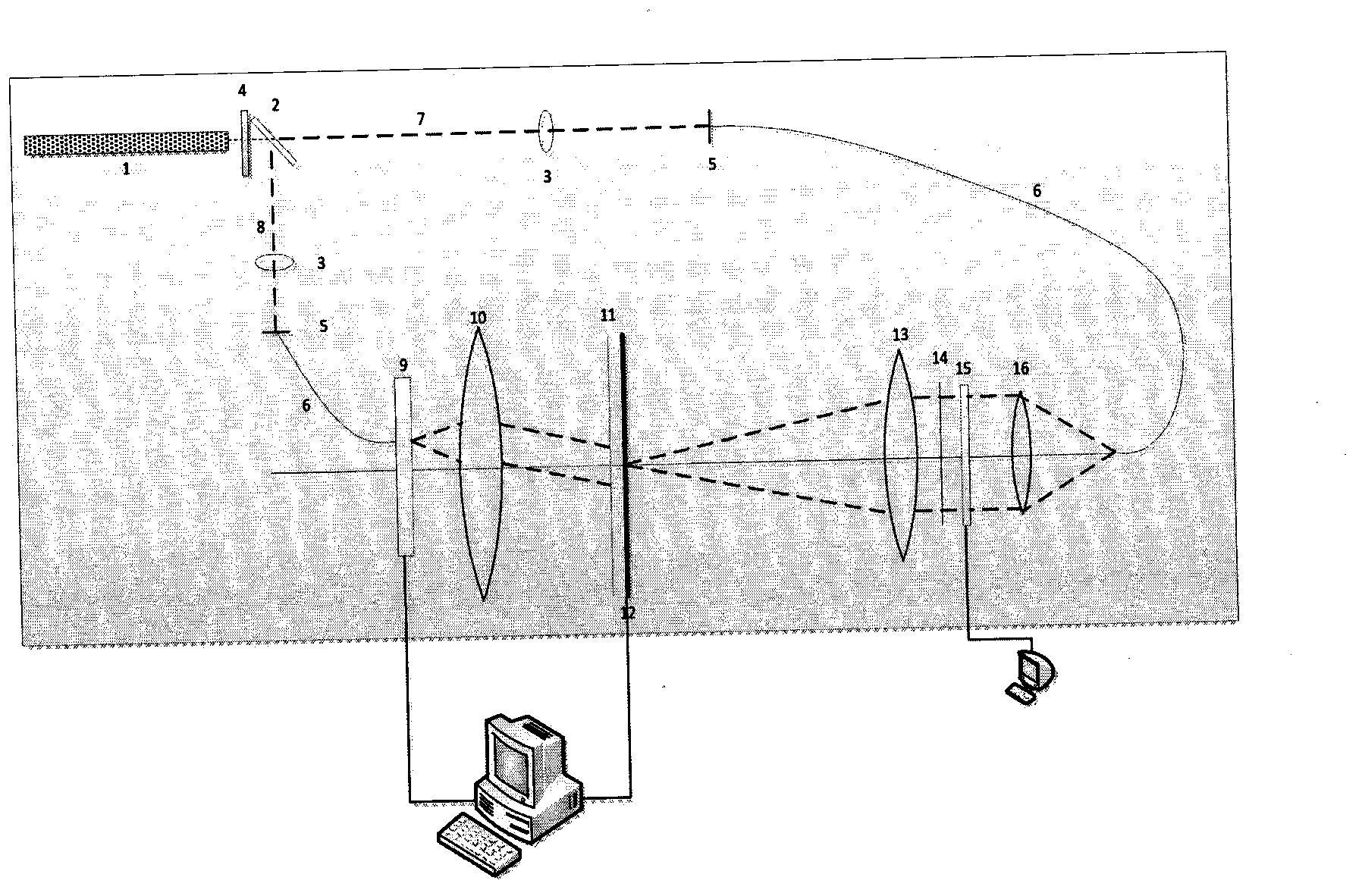

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] figure 1 In the example described, a beam of monochromatic coherent light emitted by a coherent laser light source 1 is divided into two beams of object light 7 and reference light 8 via a beam splitter 2 . 3 is a polarizer, which is used to control the ratio between the object light 7 and the reference light 8 . 4 is an optical shutter, controlled by a computer. 5 is a fiber coupling lens, and the object light 7 and the reference light 8 are transmitted to the polarization-maintaining fiber 6 via 5 . The reference light 8 is transmitted to the mechanical translation system 9 via an optical fiber, and the plane position of the 9 is the focal plane of the scanning lens 10, which can move along the x-axis and the y-axis, so as to control the distance of the reference light incident on the holographic material 12 angle. 11 is a reference light shielding plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com