Corn-free pig feed

A pig feed and corn technology, applied in animal feed, animal feed, application, etc., can solve the problem of low utilization rate of secondary powder, achieve the effect of reducing feed cost, improving utilization rate, and ensuring nutritional needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

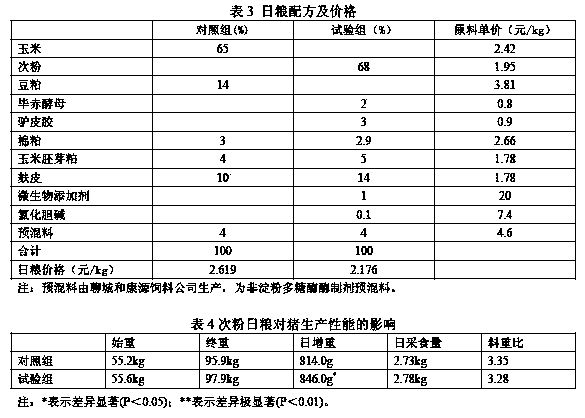

[0020] A total of 64 Dudachang three-way hybrid pigs with a body weight of 60.0±0.5kg were selected in Pingyin pig farm, and were randomly divided into control group and test group, with 4 replicates in each group and 8 pigs in each replicate. The control group was fed corn diet, and the test group was fed corn diet. The diet formula and raw material prices are shown in Table 1. The corn diet of the control group was the basic diet prepared according to the national pig nutrition standard in 2004, and its specific indicators were: digestible energy 13.4MJ / kg, crude protein 14.8%, and lysine 0.72%. The pre-feeding period is 7 days and the official period is 42 days. During the whole experiment, the pigs were raised on the cement floor, and the manure was dried and cleaned manually. Feed intake, daily gain, and feed-to-meat ratio were counted during the experiment. The test data were analyzed by T test using SAS software (version 8.1). The test results are shown in Table 2. ...

example 2

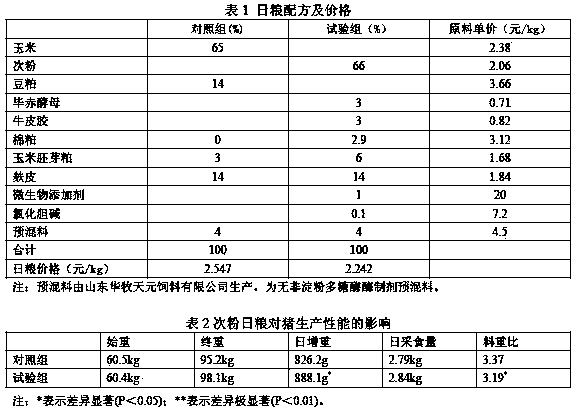

[0025] In the Liaocheng pig farm, 80 Du long-term three-way hybrid pigs with a weight of 55.5±0.5kg were selected and randomly divided into a control group and an experimental group, with 5 replicates in each group and 8 pigs in each replicate. The control group was fed corn diet, and the test group was fed corn diet. Table 3 shows the diet formula and raw material prices. The corn diet of the control group was the basic diet prepared according to the national pig nutrition standard in 2004, and its specific indicators were: digestible energy 13.4MJ / kg, crude protein 15.5%, and lysine 0.81%. The pre-feeding period is 7 days and the official period is 50 days. During the whole experiment, the pigs were raised on the cement floor, and the manure was dried and cleaned manually. Feed intake, daily gain, and feed-to-meat ratio were counted during the experiment. The test data were analyzed by T-test using SAS software. The test results are shown in Table 4.

[0026] The prepara...

example 3

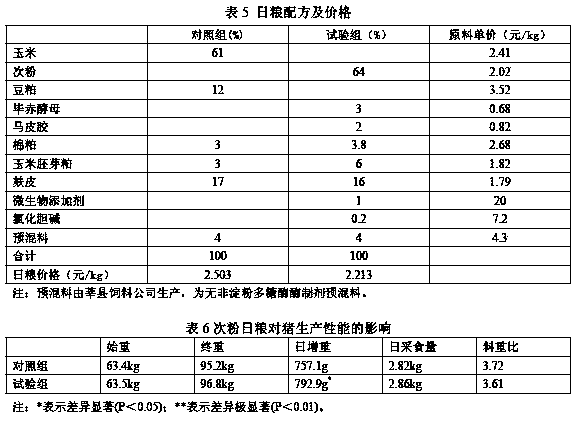

[0030] Forty pigs with a body weight of 63.0±0.5kg were selected from Yanggu county pig farm and randomly divided into control group and test group, with 4 replicates in each group and 5 pigs in each replicate. The control group was fed corn ration, and the test group was fed corn ration. See Table 5 for the ration formula and raw material prices. The corn diet of the control group was the basic diet prepared according to the national pig nutrition standard in 2004, and its specific indicators were: digestible energy 13.4MJ / kg, crude protein 14.5%, and lysine 0.70%. The pre-feeding period is 7 days and the official period is 42 days. During the whole experiment, the pigs were raised on the cement floor, and the manure was dried and cleaned manually. Feed intake, daily gain, and feed-to-meat ratio were counted during the experiment. The test data were analyzed by T-test using SAS software. The test results are shown in Table 6.

[0031] The preparation method of the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com