High-temperature resistant xylanase containing feed additive and application thereof

A feed additive and xylanase technology, applied in the field of feed additives, can solve the problems of high temperature resistance, xylanase inactivation, etc., and achieve the effects of reducing the viscosity of chyme, reducing the rate of diarrhea, and saving crude protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

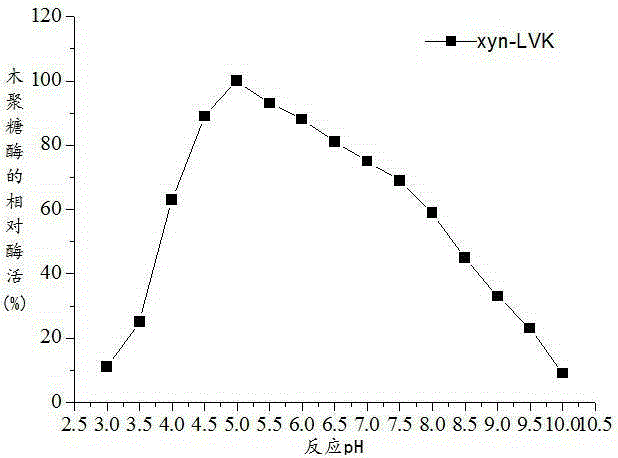

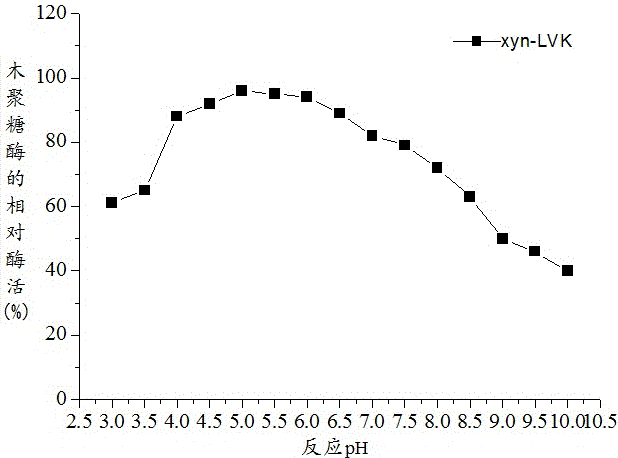

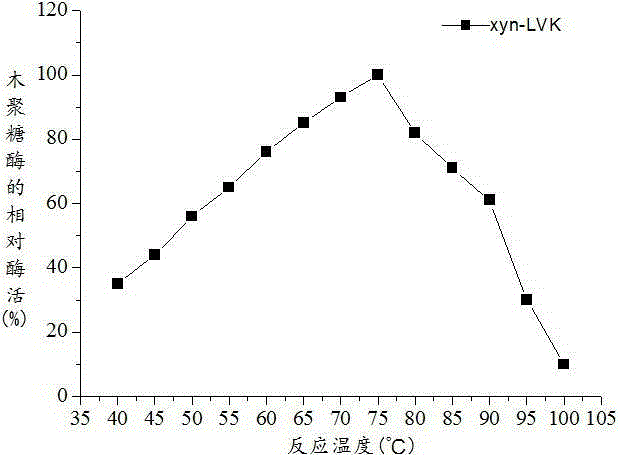

[0034] Embodiment 1: the preparation of thermostable xylanase xyn-LVK

[0035] 1. Experimental conditions

[0036] (1) Strains and vectors

[0037] Escherichia coli E. coli Top10 was purchased from Invitrogen, Trichoderma reesei QM9414 was purchased from American Type Culture Collection (ATCC), and pUC19 and pMD19-T simple vector were purchased from TaKaRa. Plasmid pAN7-1 (with fungal selection marker hygromycin resistance gene hph and E. coli selection marker ampicillin resistance gene Ap).

[0038] (2) Enzymes and other biochemical reagents

[0039] Various DNA tool enzymes, DNA Marker, DNA Gel Recovery and Purification Kit (Agarose Gel DNA Purification Kit), DNA Purification Kit (Fragment Purification Kit Ver. 2.0) were purchased from TaKaRa. T4 DNA ligase was purchased from Fermetas. Other biochemical reagents were purchased from Shanghai Sangon Bioengineering Technology Service Co., Ltd.

[0040] (3) Medium

[0041] LB medium: for cultivating Escherichia coli, conta...

Embodiment 2

[0076] The formula of the feed additive is as follows (mass fraction): xylanase xyn-LVK 10%, dextranase 15%, cellulase 1.5%, mannanase 0.75%, protease 20%, (soybean meal + DDGS) 52.75 %.

[0077] The enzyme activity of xylanase xyn-LVK in the feed additive is 10000 u / g, the enzyme activity of dextranase is 3000 u / g, the enzyme activity of cellulase is 300 u / g, and the activity of mannanase The enzyme activity is 300 u / g, and the enzyme activity of protease is 20000 u / g.

Embodiment 3

[0079] The formula of the feed additive was as follows (mass fraction): xylanase xyn-LVK 12%, glucanase 13%, cellulase 2.5%, mannanase 1%, protease 18%, DDGS 53.5%.

[0080] The enzyme activity of xylanase xyn-LVK in the feed additive is 12000 u / g, the enzyme activity of dextranase is 2600 u / g, the enzyme activity of cellulase is 500 u / g, and the activity of mannanase The enzyme activity is 400 u / g, and the enzyme activity of protease is 18000 u / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com