Amino acid concentration system

A concentration system and amino acid technology, applied in the field of fine chemical production, can solve the problems of low condenser efficiency, high evaporation temperature, and large energy consumption, and achieve the effects of reducing water consumption, improving efficiency, and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

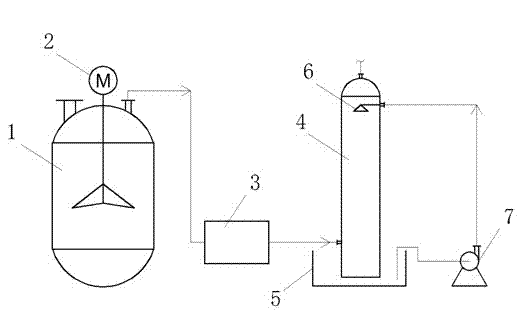

[0015] In the amino acid concentration system of the present invention, the connection relationship of each device is as follows: figure 1 As shown, it includes a concentration kettle 1, a vacuum device 3 and a gas scrubber, the concentration kettle 1 is provided with a stirring device 2, the motor of the stirring device 2 is a servo motor, and the top of the concentration kettle 1 is provided with a nozzle and the Vacuuming device 3 is connected, and the outlet of described vacuuming device 3 is connected with gas scrubbing device, and described scrubbing device can be the scrubbing device of any form, as forms such as bubbling absorption or spray absorption etc., make the hydrochloric acid in the evaporating gas dissolve in the absorption fluid.

[0016] In the amino acid concentration system of the present invention, the gas scrubbing device includes two rinsing cylinders 4 connected in series, a liquid seal tank 5 and a circulation pump 7 for absorbing liquid circulation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com