Phenolic resin stirring tank

A phenolic resin, stirring tank technology, applied in mixers with rotary stirring devices, dissolution, chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of complex structure and poor material stirring performance, and achieve good The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

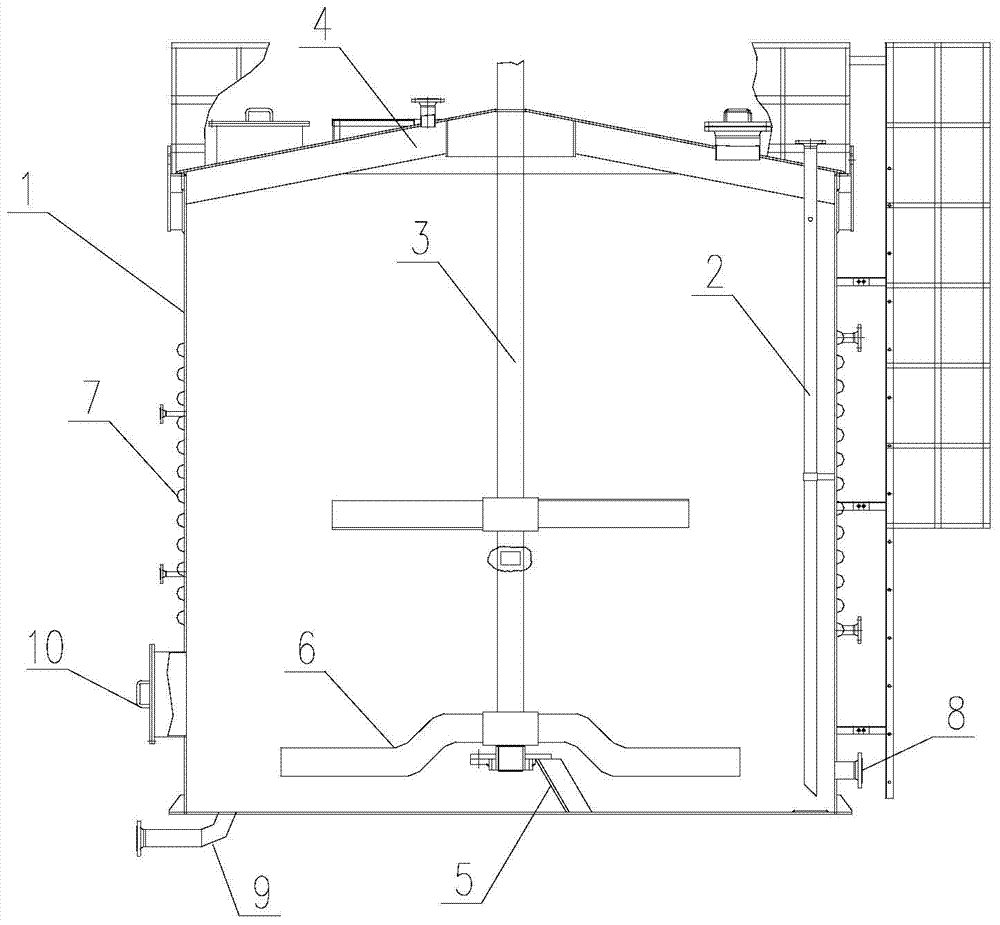

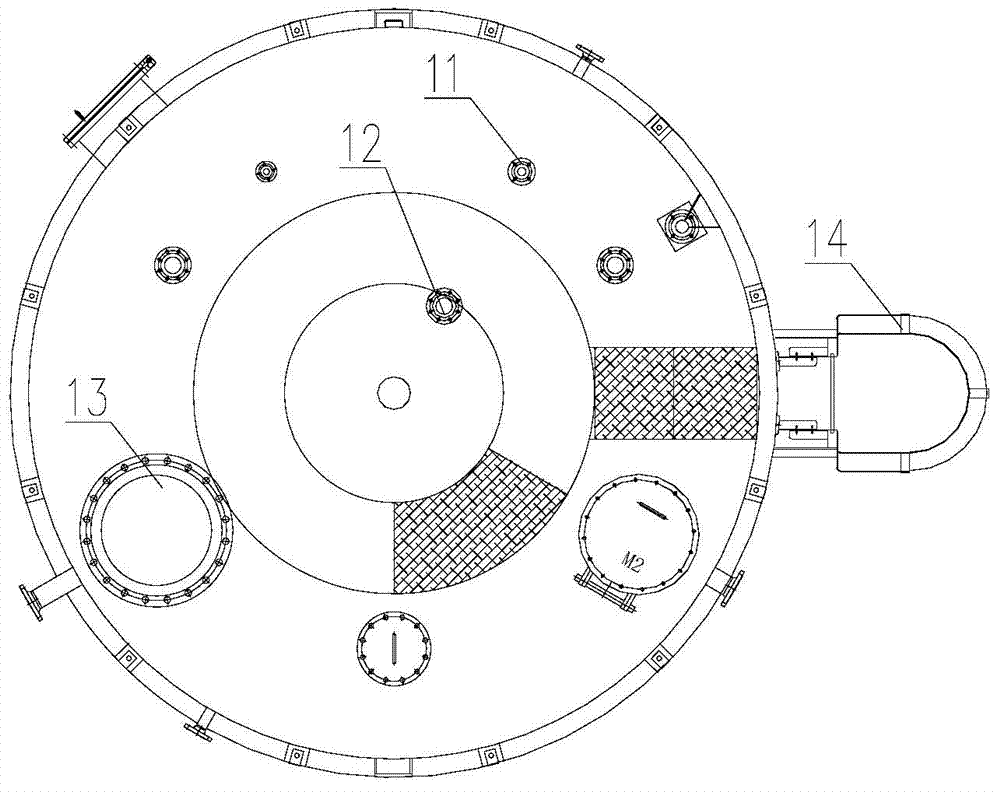

[0024] Such as figure 1 As shown, this embodiment provides a phenolic resin stirring device including a tank body 1 and a feed pipe 2 , wherein a main shaft 3 is arranged at the centerline of the tank body 1 . One end of the main shaft 3 is rotatably connected with the end cover 4 of the tank body 1, and the other end is rotatably connected with the support frame 5 arranged at the bottom of the tank body 1. The bottom and the middle of the main shaft 3 are provided with a stirring impeller 6, which is connected with the main shaft 3 The driving motor drives the main shaft 3 and the stirring impeller 6 arranged on the main shaft 3 to rotate, so that the materials participating in the reaction in the tank body 1 can be stirred. At the same time, since the middle and bottom of the main shaft 1 are equ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap