Supported gold-platinum duplex metal alloy catalyst and preparation method and application thereof

A technology of bimetallic catalysts and alloy catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to synthesize azobenzene and harsh reaction conditions and other problems, to achieve the effect of controllable alloy composition ratio, good repeatability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

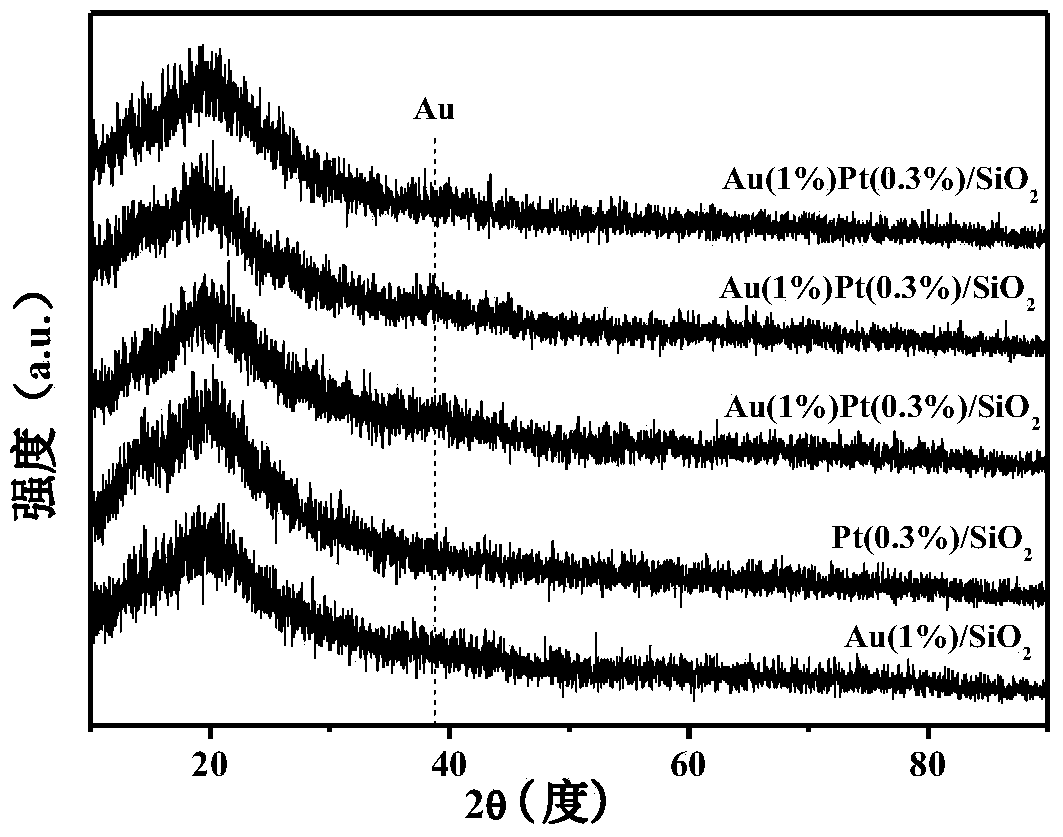

[0024] Example 1: Au(0.5)-Pt(0.1) / SiO 2 Catalyst preparation

[0025] Step 1. Preparation of silica carrier: Mix 10g APTES (3-aminopropyltriethoxysilane) and 100ml deionized water evenly, then add 2ml HCHO solution under stirring, continue to stir and hydrolyze for 12h, and then dissolve the obtained The white suspension was filtered and washed, and dried at 200° C. for 4 hours to obtain a silica carrier with reducing functional groups.

[0026] Step 2, preparation of the gold-platinum bimetallic alloy catalyst supported by silica: 5.23mg HAuCl 4 4H 2 O and 1.33 mg H 2 PtCl 6 ·6H 2 O was dissolved in 75ml of deionized water, and after stirring evenly, 0.5g of the silica carrier prepared in step 1 was added, and then refluxed at 110°C for 2h. )-Pt(0.1) / SiO 2 Bimetallic alloy catalyst.

Embodiment 2

[0027] Example 2: Au(0.5)-Pt(0.3) / SiO 2 Catalyst preparation

[0028] Step 1. Preparation of silica carrier: Mix 10g APTES (3-aminopropyltriethoxysilane) and 100ml deionized water evenly, then add 2ml HCHO solution under stirring, continue to stir and hydrolyze for 12h, and then dissolve the obtained The white suspension was filtered and washed, and dried at 200° C. for 4 hours to obtain a silica carrier with reducing functional groups.

[0029] Step 2, preparation of the gold-platinum bimetallic alloy catalyst supported by silica: 5.23mg HAuCl 4 4H 2 O and 3.98 mg H 2 PtCl 6 ·6H 2 O was dissolved in 75ml of deionized water, after stirring evenly, 0.5g of the silica carrier prepared in step 1 was added, then refluxed at 110°C for 2h, after cooling to room temperature, it was filtered and washed with water, and dried at 120°C overnight to obtain Au (0.5 )-Pt(0.3) / SiO 2 Bimetallic alloy catalyst.

Embodiment 3

[0030] Embodiment 3: Au(0.5)-Pt(0.5) / SiO 2 Catalyst preparation

[0031] Step 1. Preparation of silica carrier: Mix 10g APTES (3-aminopropyltriethoxysilane) and 100ml deionized water evenly, then add 2ml HCHO solution under stirring, continue to stir and hydrolyze for 12h, and then dissolve the obtained The white suspension was filtered and washed, and dried at 200° C. for 4 hours to obtain a silica carrier with reducing functional groups.

[0032] Step 2, preparation of the gold-platinum bimetallic alloy catalyst supported by silica: 5.23mg HAuCl 4 4H 2 O and 6.64 mg H 2 PtCl 6 ·6H 2O was dissolved in 75ml of deionized water, and after stirring evenly, 0.5g of the silica carrier prepared in step 1 was added, and then refluxed at 110°C for 2h. )-Pt(0.5) / SiO 2 Bimetallic alloy catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com