Automatic dust removing device for cooler for forced oil circulation power transformer and dust removing method thereof

A technology for power transformers and strong oil circulation, which is applied in the direction of transformer/inductor cooling, chemical instruments and methods, cleaning methods and appliances, etc., and can solve the problem of temperature rise of power transformers with strong oil circulation, affecting heat dissipation efficiency, and reducing heat dissipation efficiency, etc. problem, to achieve the effect of cooling and heat dissipation, and to ensure the effect of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

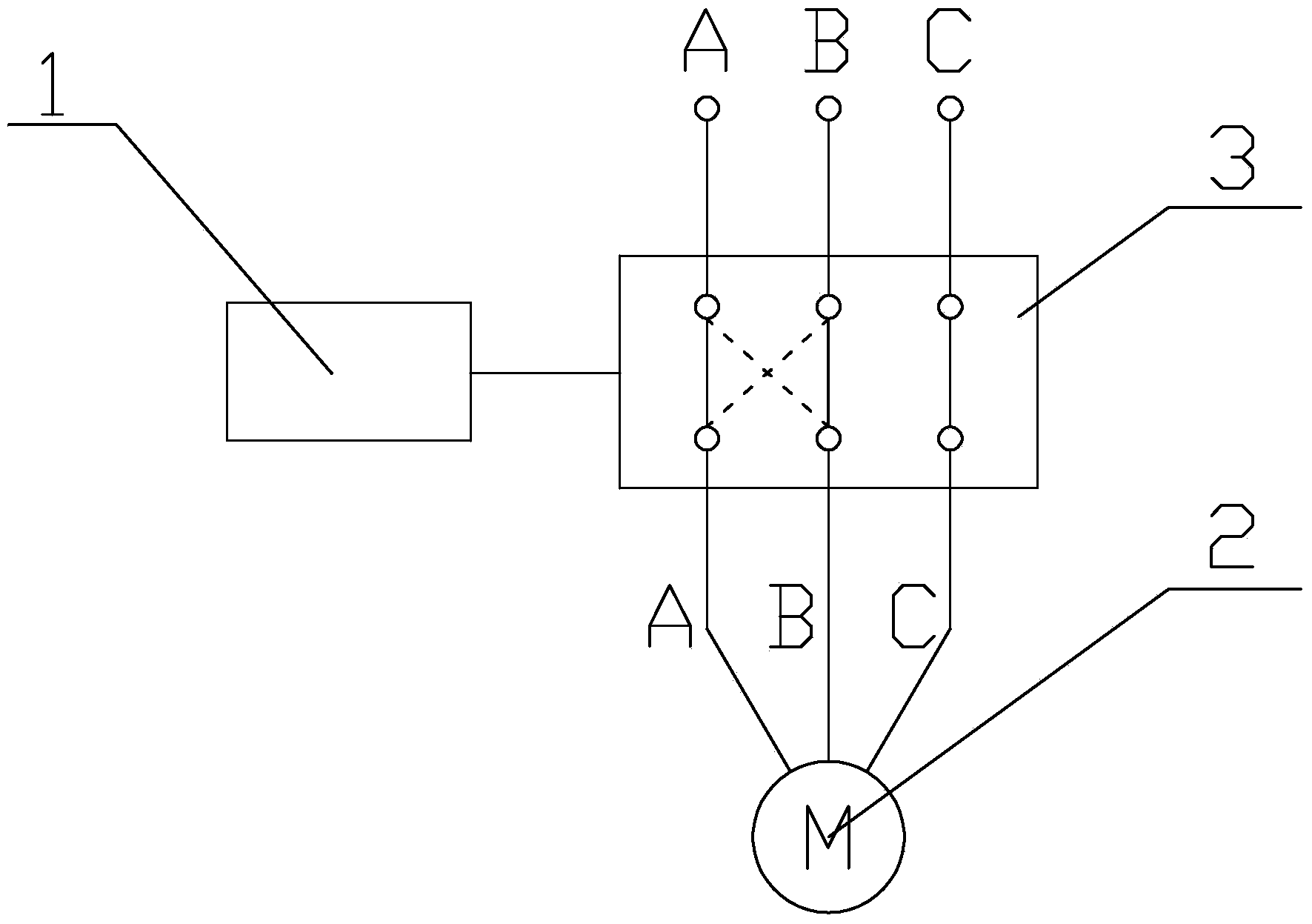

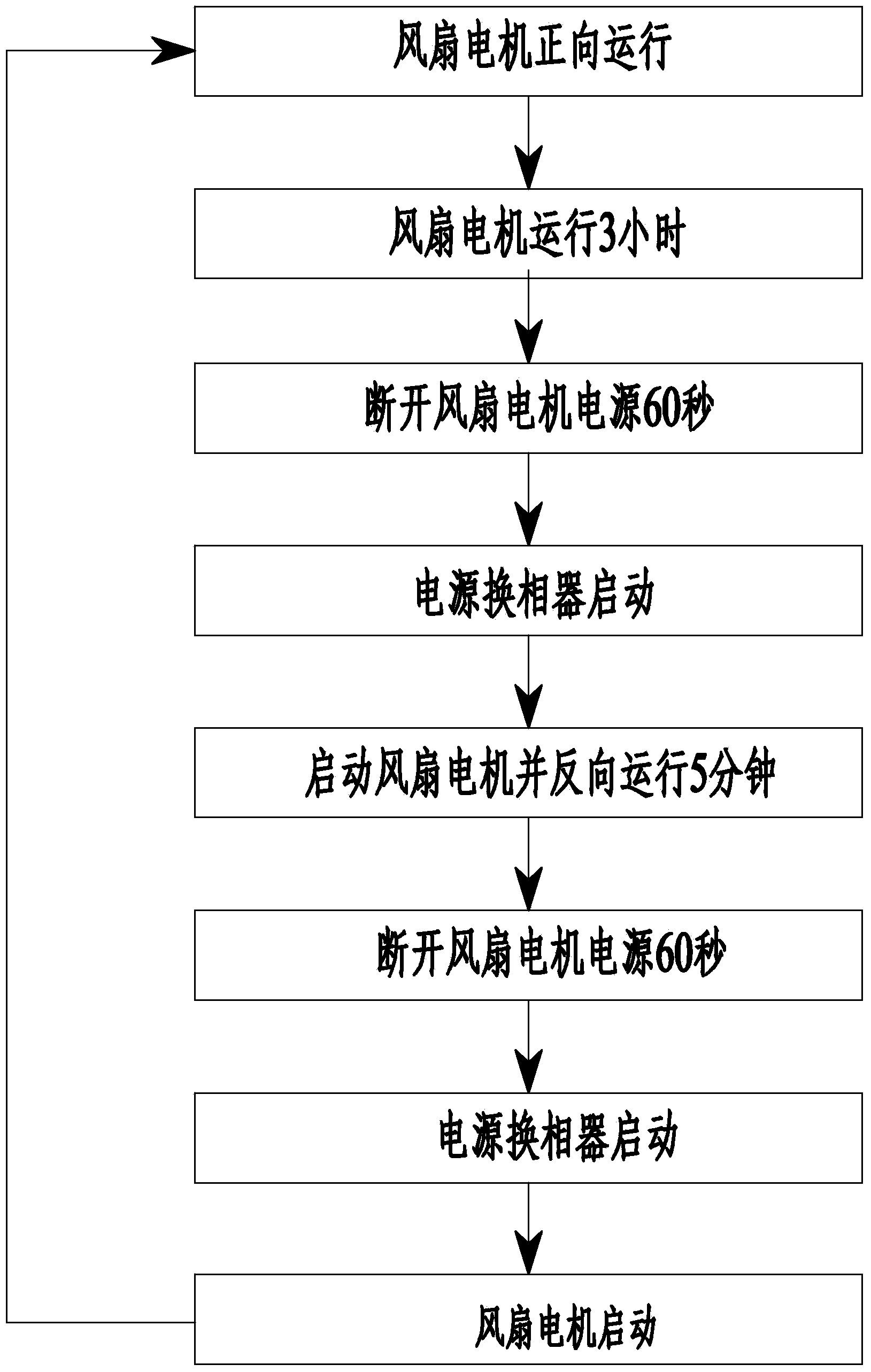

[0025] Embodiment 1: as figure 1 and figure 2As shown, the automatic dedusting device for the cooler of the strong oil circulation power transformer of the present invention comprises a strong oil circulation power transformer and a cooler for the strong oil circulation power transformer, and is provided with a controller 1, a commutation device, a voltage transformer, Current transformer, the signal output terminal of controller 1 is connected to the signal input terminal of the phase change device, and the three-phase input terminal of phase change device 3 is respectively connected to the low-voltage outlet terminal of the strong oil circulation power transformer through the voltage transformer and current transformer, and the strong oil circulation The cooler for the power transformer is provided with a fan driven by the motor 2 , and the three-phase output end of the commutation device 3 is connected to the power input end of the motor 2 . When the motor 2 driving the f...

Embodiment 2

[0026] Embodiment 2: On the basis of the structure described in Embodiment 1, the controller 1 is provided with a human-computer interaction panel, the human-computer interaction interface includes a display and a regulator, and the human-computer interaction interface is connected to the controller 1 through a communication line. According to the air pollution situation of the use site and the fan deceleration time of the cooler for the strong oil circulation power transformer, the forward rotation time, reverse time and deceleration time of the fan of the cooler for the strong oil circulation power transformer can be adjusted to improve the power of the strong oil circulation power transformer Heat dissipation efficiency of coolers for transformers.

Embodiment 3

[0027] Embodiment 3: On the basis of the structure described in Embodiment 2, a steel wire mesh cover is arranged outside the cooler for a power transformer with strong oil circulation. The large plastic paper can be blocked outside the steel wire mesh cover to prevent the plastic paper from contacting the finned tubes of the cooler for the strong oil circulation power transformer, because the temperature of the finned tubes of the cooler for the strong oil circulation power transformer is often high, which will make the The plastic sheet melted and stuck and couldn't be blown off.

[0028] Below in conjunction with the present invention, the embodiment of the automatic dedusting device for the cooler of the strong oil circulation power transformer is further described:

[0029] like figure 1 and figure 2 As shown, the automatic dedusting method for a cooler of a strong oil circulation power transformer according to the present invention, the method is as follows: the signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com