Method for recycling nitrogen and phosphorus from biogas slurry in pig farms

A recovery method and technology for pig farms are applied in the field of nitrogen and phosphorus recovery from biogas slurry in pig farms, which can solve problems such as processing difficulties and achieve the effect of reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

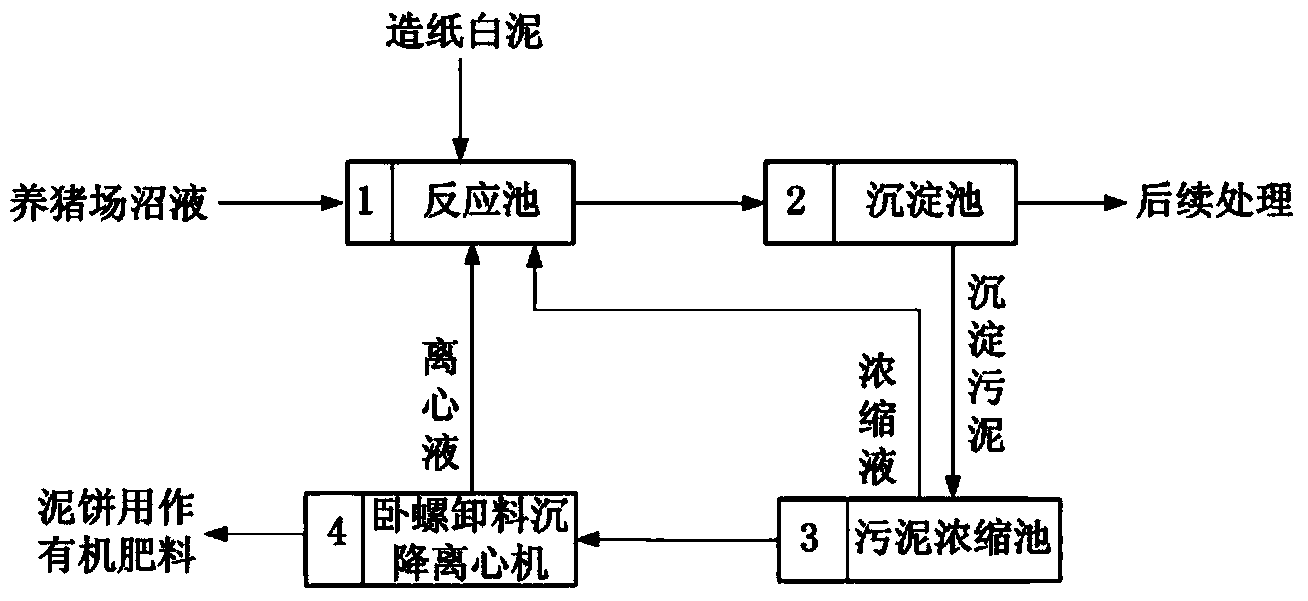

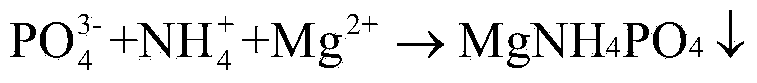

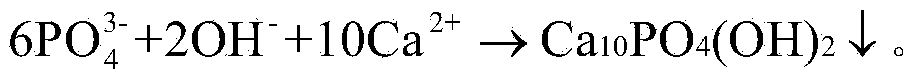

[0019] What this embodiment deals with is 120m 3 Pig farm biogas slurry 1: its The concentration is 42.95mg / L, The concentration is 418.56mg / L. The specific implementation steps are as follows: First, the biogas slurry enters the reaction tank 1, and 1200 kg of papermaking lime mud powder that has been dried, ground and modified is added to make the pH value of the biogas slurry 9.5, and stirred for 15 minutes at a stirring speed of 200 r / min. Add KH to the mud 2 PO 4 3.88kg, MgCl 2 ·6H 2 6.07kg. The mixed solution reacted in the reaction tank 1 flows into the sedimentation tank 2 by gravity, stays in the sedimentation tank 2 for 20-30 minutes, and the supernatant in the sedimentation tank 2 The concentration is 3.74mg / L, The concentration was 35.57mg / L, and the removal rates were 91.29% and 91.50%, respectively. After the settled sludge is concentrated in the sludge thickening tank 3, the concentrated solution is returned to the reaction tank 1, and the concentra...

Embodiment 2

[0021] What this embodiment deals with is 190m 3 Pig farm biogas slurry 2: its The concentration is 85.64mg / L, The concentration is 796.82mg / L. The specific implementation steps are as follows: First, the biogas slurry enters the reaction tank 1, and 1900 kg of dried and ground paper-making lime mud powder is added to make the pH value of the biogas slurry 9.5, and stirred for 15 minutes at a stirring speed of 200 r / min. K H 2 PO 4 7.36kg, MgCl 2 ·6H 2 O11.55kg. The mixed solution reacted in the reaction tank 1 flows into the sedimentation tank 2 by gravity, stays in the sedimentation tank 2 for 20-30 minutes, and the supernatant in the sedimentation tank 2 The concentration is 5.67mg / L, The concentration was 62.35mg / L, and the removal rates were 93.38% and 92.18%, respectively. After the settled sludge is concentrated in the sludge thickening tank 3, the concentrated solution is returned to the reaction tank 1, and the concentrated sludge is dehydrated by the deca...

Embodiment 3

[0023] What this embodiment deals with is 80m 3 Pig farm biogas slurry 3: its The concentration is 53.18mg / L, The concentration is 674.26mg / L. The specific implementation steps are as follows: First, the biogas slurry enters the reaction tank 1, and 800 kg of papermaking lime mud powder that has been dried, ground and modified is added to make the pH of the biogas slurry 9.5, and stirred for 15 minutes at a stirring speed of 200 r / min. Add KH to the mud 2 PO 4 6.32kg, MgCl 2 ·6H 2 O9.78kg. The mixed solution reacted in the reaction tank 1 flows into the sedimentation tank 2 by gravity, stays in the sedimentation tank 2 for 20-30 minutes, and the supernatant in the sedimentation tank 2 The concentration is 3.85mg / L, The concentration was 43.37mg / L, and the removal rates were 92.76% and 93.57%, respectively. After the settled sludge is concentrated in the sludge thickening tank 3, the concentrated solution is returned to the reaction tank 1, and the concentrated slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com