Water treatment method for oxidation algae removal with high-activity singlet oxygen

A singlet oxygen and high activity technology, applied in the field of algae removal, can solve the problems of high investment and operation costs, potential safety hazards, inconvenient storage, etc., and achieve the effects of convenient storage, easy transportation and easy access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

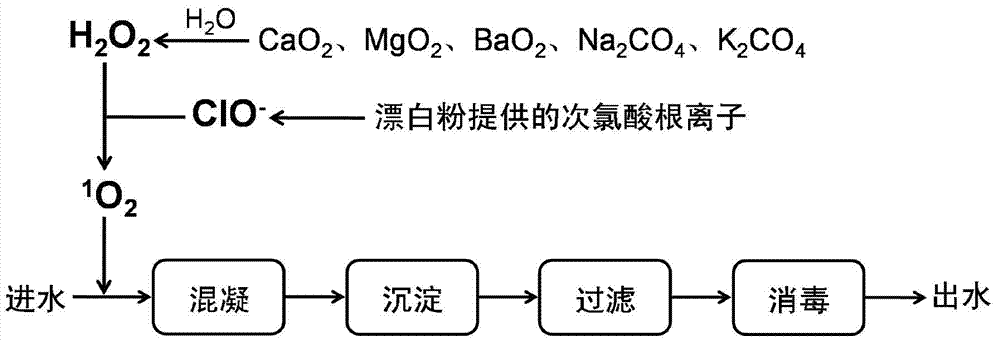

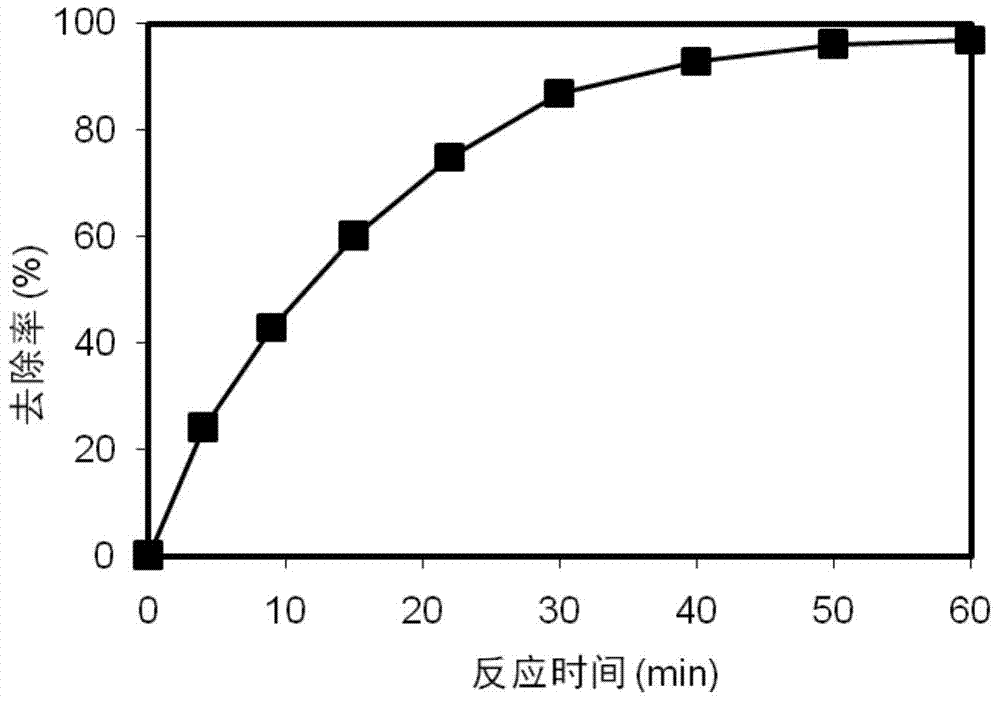

[0021] Specific embodiment one: this embodiment is a water treatment method utilizing highly active singlet oxygen to oxidize and remove algae, and it is realized by the following steps: a, solid bleaching powder and inorganic solid peroxide are according to mass ratio (1~10 ): 1 is added to the algae-containing water, stirred, and under the condition that the peroxide concentration is 10-1000 mg / L and the reaction time is 5-60 min, algae removal is carried out; b, conventional water treatment is carried out: processing in step a After that, coagulation, sedimentation, filtration, and disinfection are carried out in sequence, and the water treatment using highly active singlet oxygen to oxidize and remove algae is completed.

[0022] The bleaching powder and the inorganic solid peroxide in this embodiment are stored separately before use.

[0023] The solid bleaching powder and the inorganic solid peroxide described in this embodiment are mixed and added according to the mass ...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of solid bleaching powder to inorganic solid peroxide is (2-9):1. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass ratio of solid bleaching powder to inorganic solid peroxide is (3-8):1. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com