Preparation method of 4,4'-diamido-2,2'-dicarboxylbiphenyl

A technology of dicarboxybiphenyl and diamino, which is applied in the field of preparation of 4,4'-diamino-2,2'-dicarboxybiphenyl, can solve problems such as being unsuitable for industrial production, and achieves good product color and environmental protection. The effect of low pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

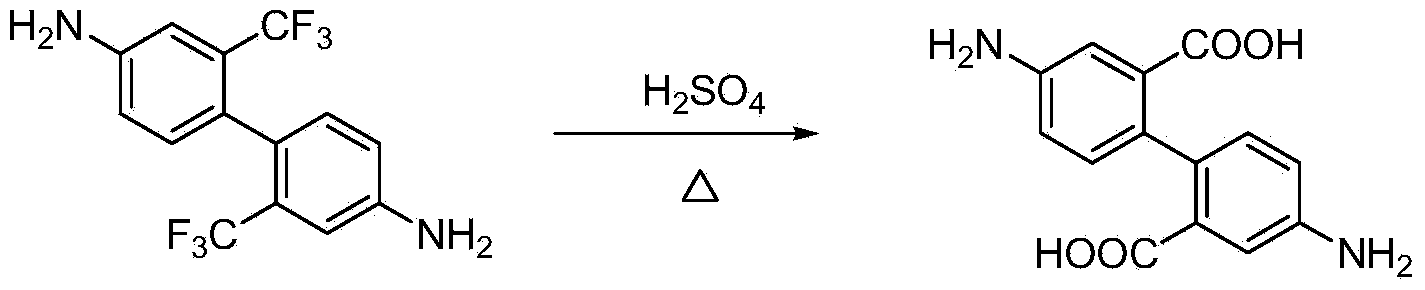

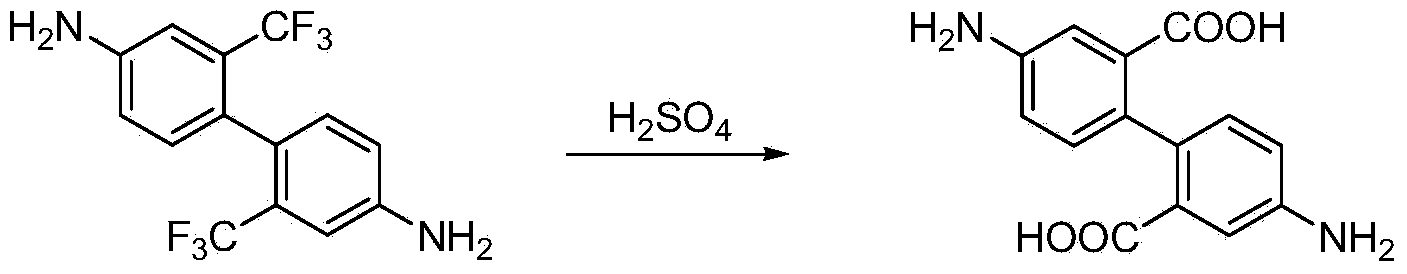

[0016] Preparation method of the present invention specifically comprises the following contents:

[0017] In step (1): 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl reacts with concentrated sulfuric acid under heating conditions to obtain 4,4'-diamino-2,2'-bis Crude carboxybiphenyl. After the reaction was complete, the reaction solution was poured into ice water, and after cooling down, sodium hydroxide was added to adjust the pH to 3-4, stirred, and then filtered to obtain the crude product. The molar ratio is 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl:concentrated sulfuric acid=1:(5.2~9.2), the preferred ratio is: 4,4'-diamino-2,2 '-bistrifluoromethylbiphenyl:concentrated sulfuric acid=1:7.2. The reaction temperature ranges from 110°C to 130°C, preferably 120°C.

[0018] In the step (2): 4,4'-diamino-2,2'-dicarboxybiphenyl is obtained by recrystallization in a polar solvent under reflux conditions. The polar solvent is methanol or ethanol; the molar ratio is: 4,4'-diam...

Embodiment 1

[0021] Add 1.35 kg of concentrated sulfuric acid to the reaction flask, and add 0.6 kg of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl in batches (the molar ratio is: 4,4'-diamino-2, 2'-bistrifluoromethylbiphenyl:concentrated sulfuric acid=1:7.2), after the addition, the temperature was raised to 110°C for 7 hours, and after the reaction was completed, it was cooled to room temperature. Pour the reaction solution into 3 kg of ice water, lower the temperature to below 10°C, add sodium hydroxide to adjust the pH to 3-4, stir for 1 hour and filter to obtain 4,4'-diamino-2,2'-dicarboxy The crude product of biphenyl is 0.36 kg, gray solid, and the crude product yield is 70.5%. The reaction structure is as follows:

[0022]

Embodiment 2

[0024] Add 1.13 kg of concentrated sulfuric acid to the reaction flask, and add 0.6 kg of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl in batches (the molar ratio is: 4,4'-diamino-2, 2'-bistrifluoromethylbiphenyl:concentrated sulfuric acid=1:6.2), after the addition, the temperature was raised to 120°C for 7 hours, and after the reaction was completed, it was cooled to room temperature. Pour the reaction solution into 2.5 kg of ice water, lower the temperature to below 10°C, add sodium hydroxide to adjust the pH to 3-4, stir for 1 hour and filter to obtain 4,4'-diamino-2,2'-dicarboxy The crude product of biphenyl was 0.38 kg, gray solid, and the crude product yield was 74.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com