Adhesive for silicone mica tape and preparation method of adhesive

A silicone rubber, silicone technology, applied in the direction of adhesives, coatings, etc., can solve the problems of inability to undergo cross-linking and curing, unfavorable electrical insulation performance of motors, and reduce the final performance of silicone-less tapes, and achieve good chemical compatibility. properties, high viscosity, and the effect of improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An adhesive for silicone-less adhesive tape of the present invention is prepared by dehydration polycondensation of phenyl vinyl silicone rubber and vinyl MQ silicone resin with a mass ratio of 10:11 under the action of dibutyltin dilaurate.

[0025] In phenyl vinyl silicone rubber, the molar ratio of methyl, phenyl, vinyl is 100:20:3, and the dynamic viscosity of phenyl vinyl silicone rubber is 8×10 4 cP.

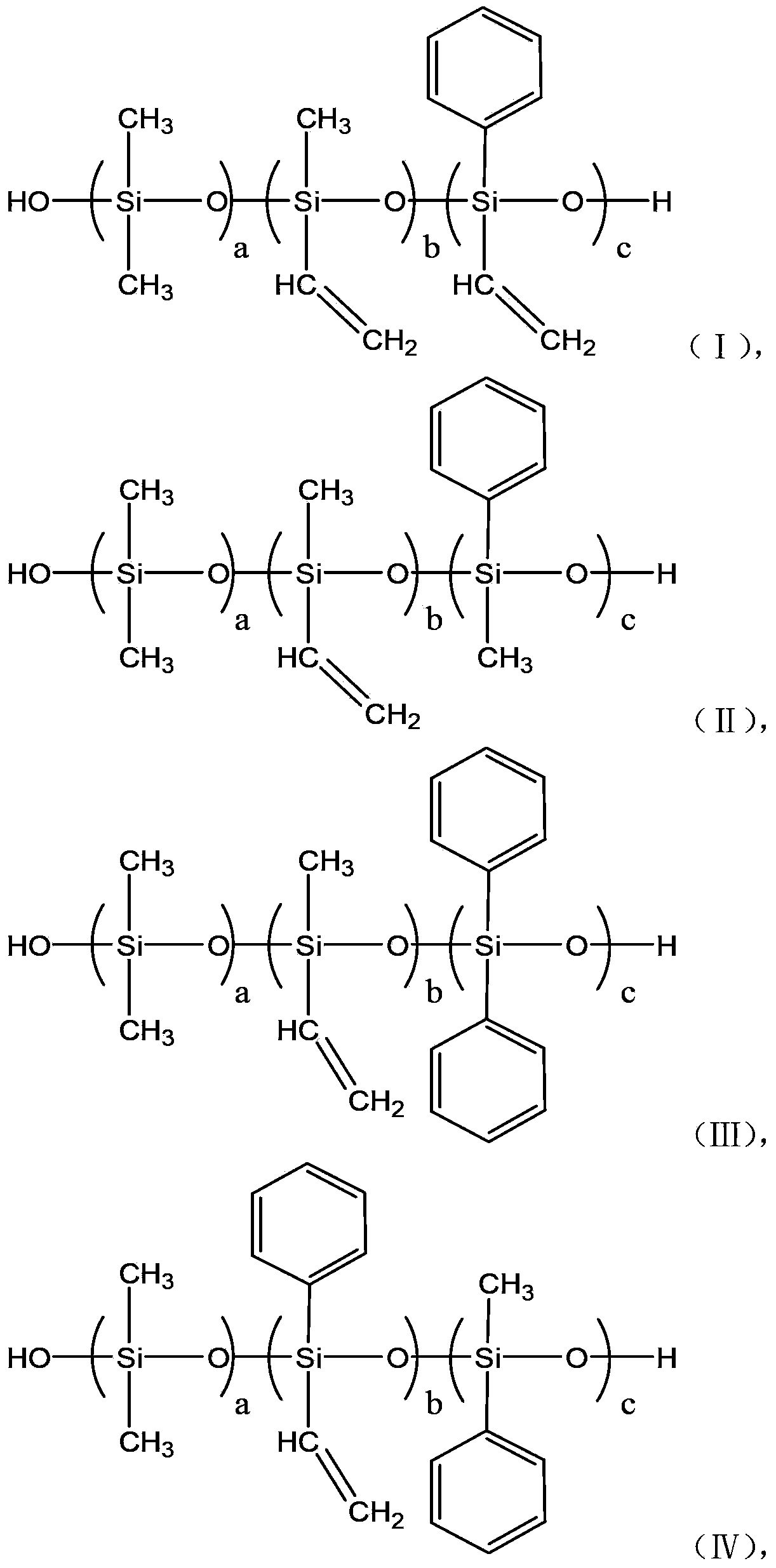

[0026] The general molecular structure formula of phenyl vinyl silicone rubber in this embodiment is:

[0027]

[0028] Among them, a, b, and c are all positive integers.

[0029] In vinyl MQ silicone resin, the molar ratio of M / Q is 0.7:1, and the molar ratio of methyl to vinyl is 100:7.

[0030] A kind of preparation method of the silicone few adhesive tape adhesive of above-mentioned present embodiment, comprises the following steps:

[0031] 100g of phenylvinyl silicone rubber is completely dissolved in 40g of toluene, the molar ratio of methyl, phenyl, vi...

Embodiment 2

[0043] An adhesive for silicone-less adhesive tape of the present invention is prepared by dehydration polycondensation of phenylvinyl silicone rubber and vinyl MQ silicone resin with a mass ratio of 10:10 under the action of a catalyst dibutyltin dilaurate.

[0044] In phenyl vinyl silicone rubber, the molar ratio of methyl, phenyl and vinyl is 100:33:7, and the dynamic viscosity of phenyl vinyl silicone rubber is 8.5×10 4 cP.

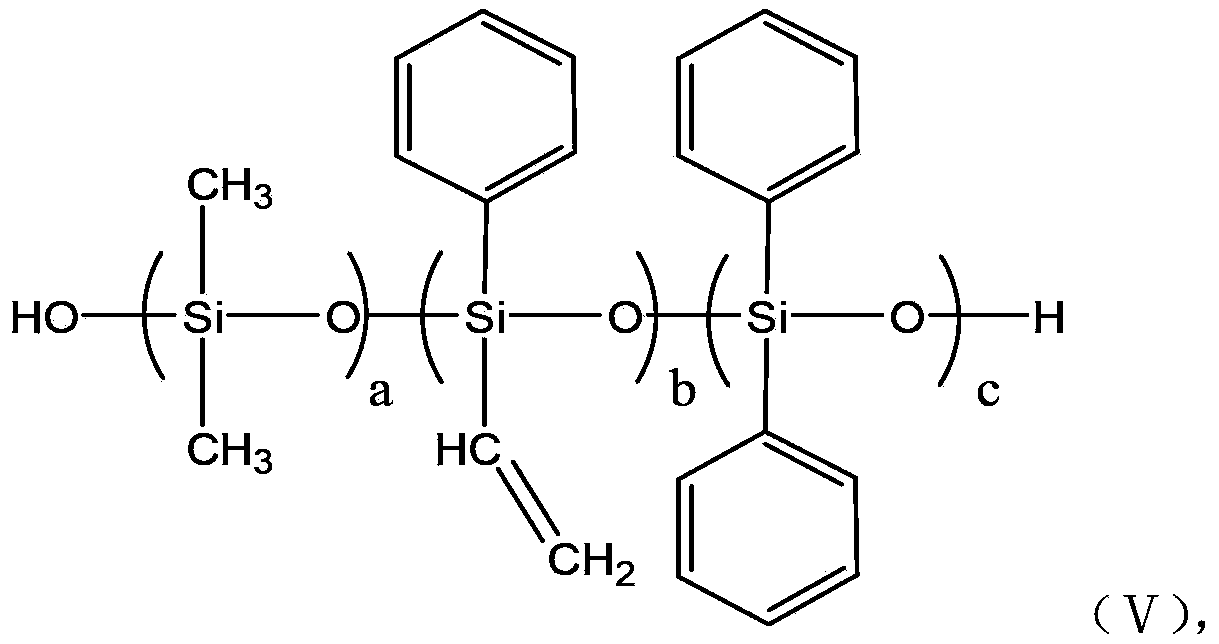

[0045] The general molecular structure formula of phenyl vinyl silicone rubber in this embodiment is:

[0046]

[0047] Among them, a, b, and c are all positive integers.

[0048]In vinyl MQ silicone resin, the molar ratio of M / Q is 0.8:1, and the molar ratio of methyl to vinyl is 100:6.

[0049] A kind of preparation method of the silicone few adhesive tape adhesive of above-mentioned present embodiment, comprises the following steps:

[0050] 100g of phenylvinyl silicone rubber is completely dissolved in 80g of toluene, the molar ratio of meth...

Embodiment 3

[0052] An adhesive for silicone-less adhesive tape of the present invention is prepared by dehydration polycondensation of phenylvinyl silicone rubber and vinyl MQ silicone resin with a mass ratio of 10:9 under the action of a catalyst dibutyltin dilaurate.

[0053] In phenylvinyl silicone rubber, the molar ratio of methyl, phenyl, and vinyl is 100:10:6, and the dynamic viscosity of phenylvinyl silicone rubber is 6.8×10 4 cP.

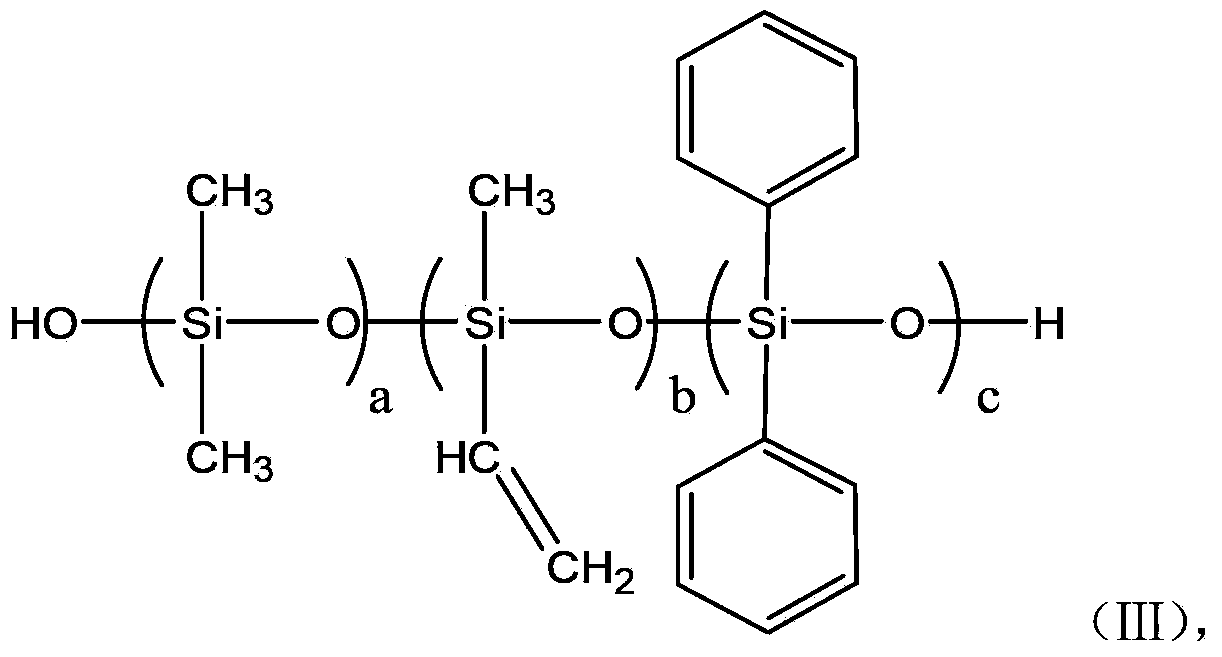

[0054] The general molecular structure formula of phenyl vinyl silicone rubber in this embodiment is:

[0055]

[0056] Among them, a, b, and c are all positive integers.

[0057] In vinyl MQ silicone resin, the molar ratio of M / Q is 0.85:1, and the molar ratio of methyl to vinyl is 100:7.

[0058] A kind of preparation method of the silicone few adhesive tape adhesive of above-mentioned present embodiment, comprises the following steps:

[0059] 100g of phenyl vinyl silicone rubber is completely dissolved in 80g of toluene, the molar ratio of met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com