Alloy melt hydrogen removal device and online hydrogen removal method thereof

A melt and alloy technology, applied in the field of metallurgy, can solve the problems of poor hydrogen removal effect and high cost of hydrogen removal, and achieve the effects of easy installation and replacement of equipment, low cost of hydrogen removal, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

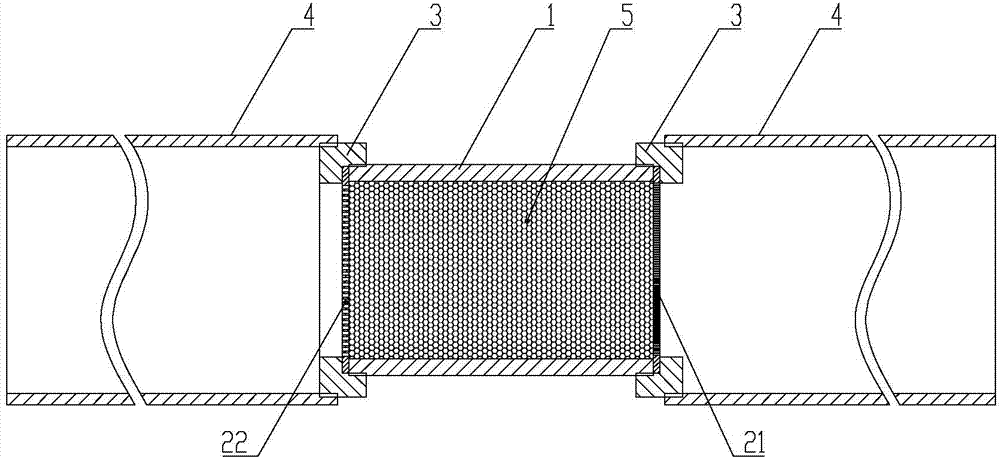

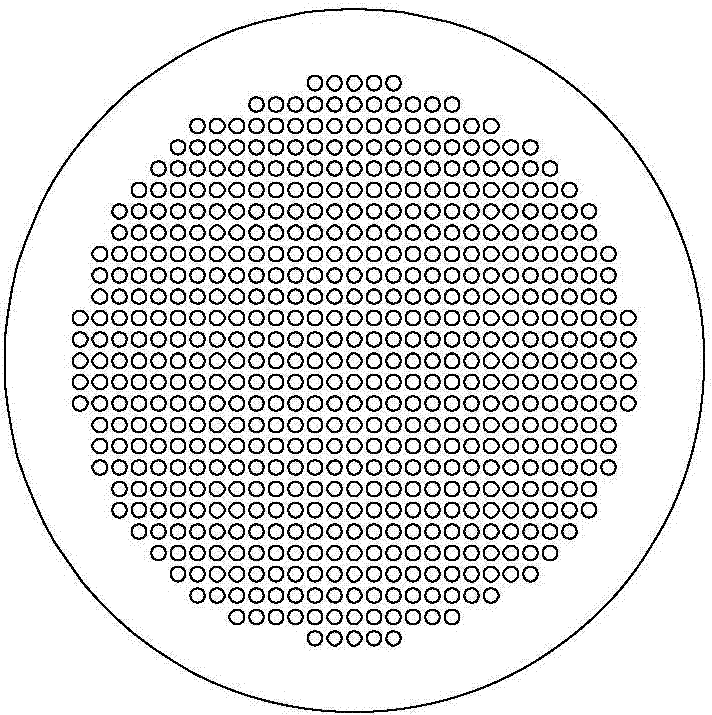

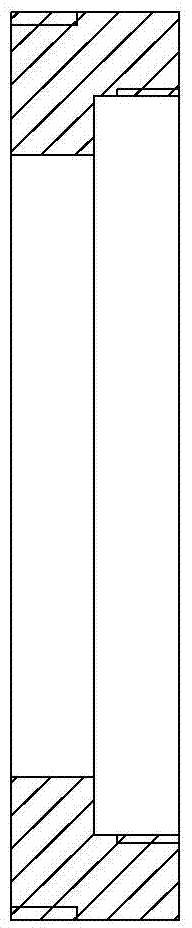

[0027] Embodiment 1 A kind of alloy melt dehydrogenation device

[0028] Such as Figures 1 to 2 As shown, the alloy melt hydrogen removal device of this embodiment includes a purification pipe 1, and the purification pipe 1 includes an alloy melt inflow end and an alloy melt outflow end, and the purification pipe 1 is uniformly filled with Mo content of 0.1 -2.0% Ti-Mo alloy particles 5, the outflow end of the alloy melt is provided with a first sealing plate 21 for filtering the Ti-Mo alloy particles 5, and the purification pipe 1 and the first sealing plate 21 are made of steel production. When in use, the alloy melt inflow end of the alloy melt dehydrogenation device can be vertically set upwards, and the alloy melt flows through the purification pipe 1 from top to bottom, and the Ti-Mo alloy particles 5 are carried out in the purification pipe 1. hydrogen absorption reaction. The alloy melt dehydrogenation device of the present invention has a simple structure, and com...

Embodiment 2

[0034] Embodiment 2 An online hydrogen removal method based on the alloy melt hydrogen removal device

[0035] An online hydrogen removal method based on the alloy melt hydrogen removal device in this embodiment includes the following steps: S1) passing one of the first sealing plate 21 and the second sealing plate 22 through the cylindrical connector 3 Connected to one end of the purification pipe 1; S2) Evenly filling the Ti-Mo alloy particles 5 into the purification pipe 1, the molybdenum element content in the Ti-Mo alloy particles 5 accounts for 0.1-2.0%, preferably 1.05%; S3 ) Connect the other one of the first sealing plate 21 and the second sealing plate 22 to the other end of the purification pipe 1 through the cylindrical connector 3; S4) Clean the installed first sealing plate 21 and the second sealing plate 22 The pipe 1 is screwed and fixedly connected to the melt flow pipe 3 through the cylindrical connector 3; S5) The alloy melt is passed into the melt flow pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com