Method for preparing microcrystalline cellulose and reaction equipment of microcrystalline cellulose

A technology of microcrystalline cellulose and production method, which is applied in the direction of pulping with acid salt/acid anhydride, can solve the problems of large amount of water and acid, achieve the effect of less usage, reduce the usage of hydrochloric acid, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

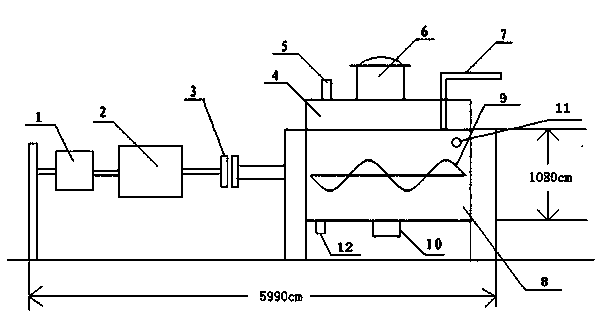

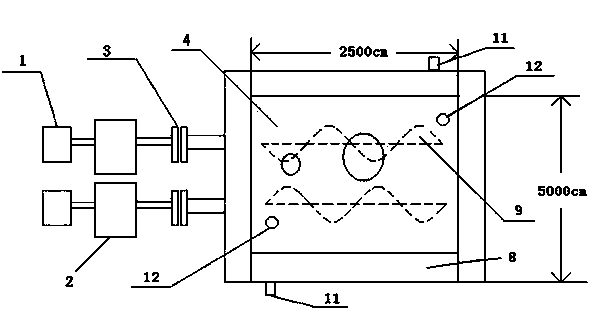

Image

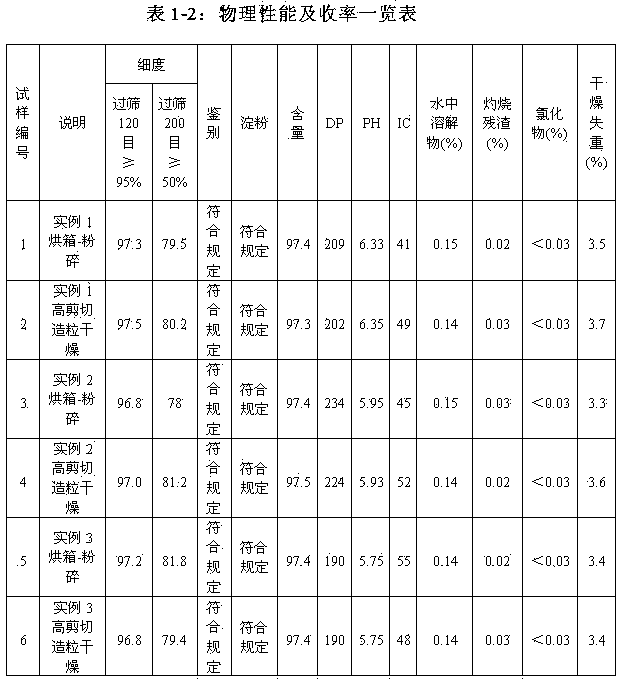

Examples

Embodiment 1

[0033] Add 1500kg deionized water into the 2000L enamel reaction kettle, start the stirring paddle, slowly add 12.0kg hydrochloric acid, and make a 0.25% dilute hydrochloric acid solution. Slowly put 500kg of wood pulp into the 4000L new biaxial differential speed high shear force reaction device, turn on the steam heating switch of the spacer, and inject the prepared dilute hydrochloric acid solution at the same time. Wood pulp was swelled and mixed in a new biaxial high-shear reaction device, sheared and depolymerized to prepare a wood pulp mixture with a solid content of 24.8%. Heat up to 90-100°C, keep warm and depolymerize for 3 hours.

[0034] The crude product obtained after heat preservation and continuous depolymerization, the appearance of the cellulose with a solid content of 1% was observed under a microscope, similar to that of cellulose produced by traditional acid hydrolysis.

[0035] Stop heating after the depolymerization is completed, stir to obtain a slurry...

Embodiment 2

[0040] Add 1500kg deionized water into the 2000L enamel reaction kettle, start the stirring paddle, slowly add 13.5kg hydrochloric acid, and make a 0.28% dilute hydrochloric acid solution. Slowly put 500kg of refined cotton into a 4000L new biaxial differential high-shear device, turn on the steam heating switch of the spacer, and inject the prepared dilute hydrochloric acid solution at the same time. Refined cotton was swollen, mixed, sheared and depolymerized in a new biaxial high-shear reaction device to prepare a refined cotton mixture with a solid content of 24.8%. Heat up to 90-100°C and keep warm for 2.5 hours to depolymerize.

[0041] The crude product obtained after heat preservation and continuous depolymerization, the appearance of the cellulose with a solid content of 1% was observed under a microscope, similar to that of cellulose produced by traditional acid hydrolysis.

[0042] Stop heating after the depolymerization is completed, stir to obtain a slurry materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com