Mining drilling and cutting integrated drill bit

A drill bit, drilling and cutting technology, used in drill bits, drilling equipment, mining equipment, etc., can solve the problems of inability to realize the integration of drilling and cutting, easy leakage at the joint of the drill pipe, easy to block the waterway, etc., so as to overcome the deep limitation of cutting holes. , The effect of overcoming equipment wear and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

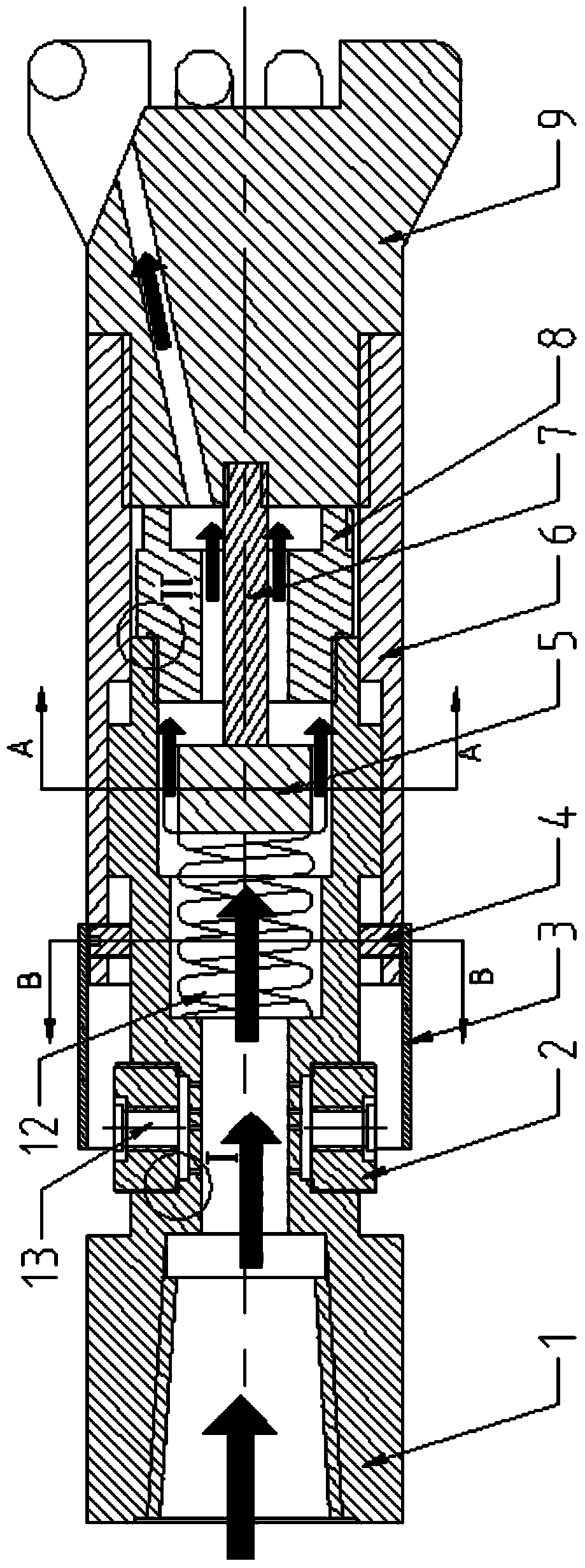

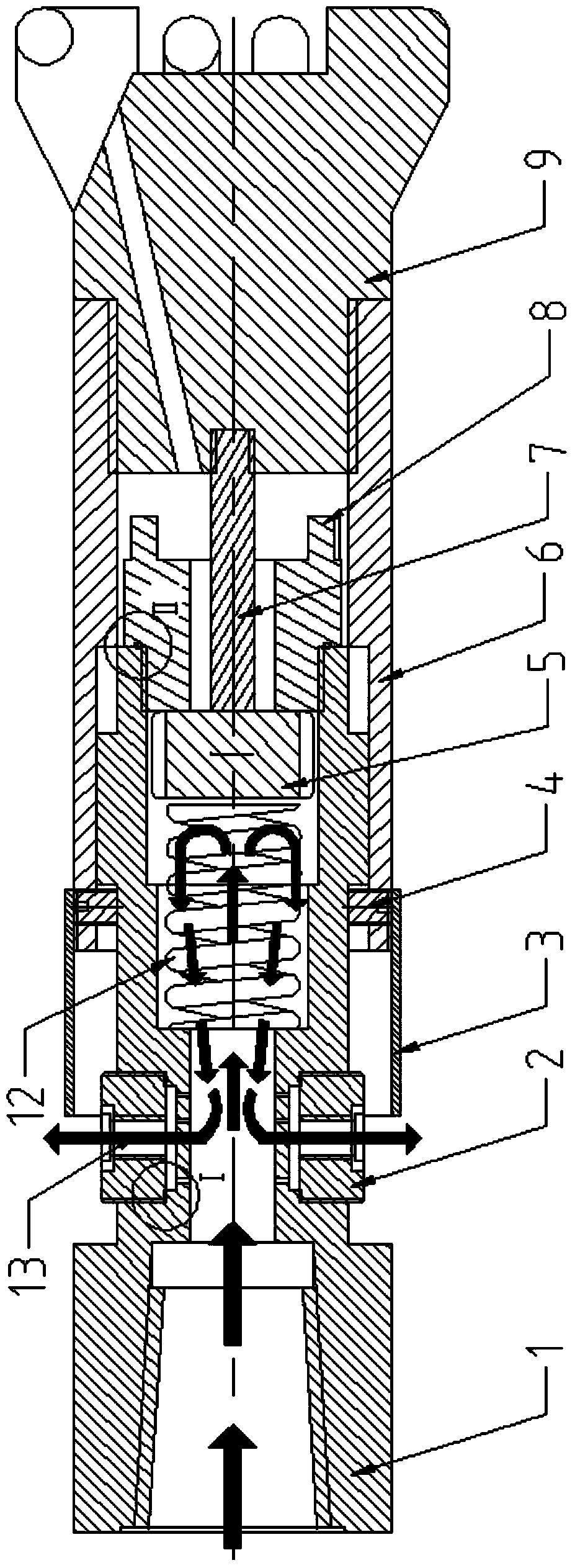

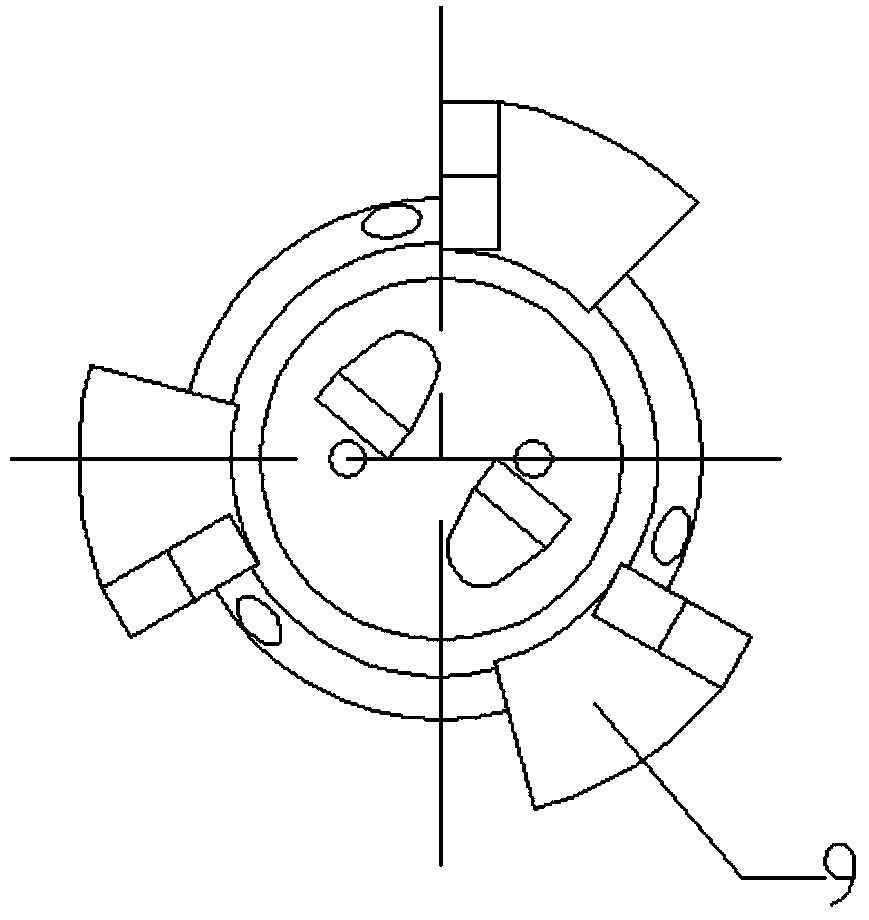

[0029] Such as figure 1 and figure 2 As shown, the mine drilling and cutting integrated drill bit of the present invention includes a main shaft 1 with an open inner cavity. A gland 8 is coaxially installed on the front end of the main shaft 1. The rear section of the gland 8 extends into the main shaft 1 and is threadedly connected with the main shaft 1. . The gland 8 is an annular structure, and its central cavity is a water flow channel. Such as Figure 7 As shown, in order to ensure sealing and pressure retention, a gland sealing ring 11 is installed at the connection between the gland 8 and the main shaft 1 . The rear end of the main shaft 1 is used to connect with the high-pressure drill pipe, specifically: the rear section of the inner cavity of the main shaft 1 is provided with an internal thread, which is threadedly connected with the high-pressure drill pipe.

[0030] A nozzle 13 for cutting coal seams is installed radially on the main shaft 1 . In order to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com