Incline hoist transportation system for subway construction and setup method thereof

A transportation system and inclined shaft technology, which is applied in the inclined shaft lifting transportation system and setting field of subway construction, can solve the problems of large material transportation, safety risks, and low handling efficiency, and achieve huge economic and social benefits and safe operation Reliable, low-investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

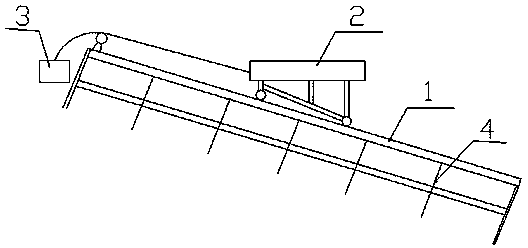

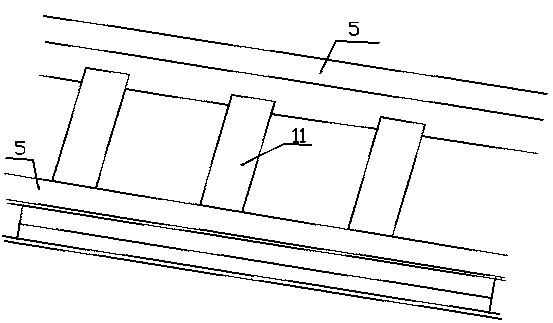

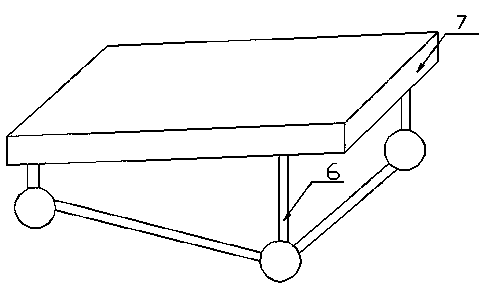

[0041] Examples see attached Figure 1-7 .

[0042] A method for setting up an inclined shaft hoisting transportation system for subway construction is characterized in that simple tracks are set on the basis of escalators for passengers going up and down the inclined shaft, and overhead tracks made of steel frames and channel steel welding are used; Install a platform freight rail car with multiple safety protection devices, using a rail car composed of a wedge-shaped frame and a horizontal cargo box; using a traction winch with a flexible soft-start mechanism to drag the rail car with a soft start, and at least one set of rail cars Automatic anti-fall mechanism; elastic buffer and traction cable are set under the wedge-shaped frame to form a soft traction mechanism, and ground brakes are set; permanent magnetic coupler is used as the coupling between the motor and reducer of the traction winch.

[0043] An inclined shaft hoisting transportation system for subway constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com