Ceramic composite-coating type corrosion-resistant valve and paint coating process of ceramic composite coating in corrosion-resistant valve

A ceramic composite and corrosion-resistant technology, which is applied to the parts in contact between the valve element and the valve seat, the coating, the device for coating liquid on the surface, etc., to achieve the effects of long service life, high technical content and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

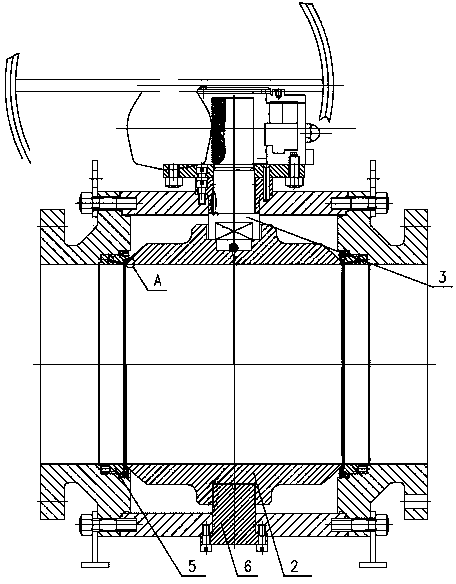

[0023] The invention provides a ceramic composite coating type corrosion-resistant valve and the coating process of the ceramic composite coating in the corrosion-resistant valve. The invention will be further described below in conjunction with the accompanying drawings:

[0024] A ceramic composite coating type corrosion-resistant valve, including an operating handle, a valve body (4), a ball (2) inside the valve body (4), a valve seat (5), a valve stem (3), and a bearing (6), the operating handle is fixedly connected to the upper end of the sphere (2) through the valve stem (3), and the lower end of the sphere (2) is fixedly connected to the bearing (6). It is characterized in that the corrosion-resistant valve is also A coating is included, and the coating is made of ceramic paint and covers the surfaces of the ball (2), the valve stem (3), the valve body (4), the valve seat (5) and the bearing (6).

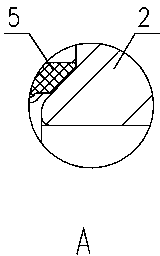

[0025] Such as figure 2 As shown, the sealing pair of the ball valve i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com