Combined type refrigeration system and method based on coupling between direct cycle and reverse cycle

A refrigeration system and composite technology, applied in the direction of refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of irreversible loss, large temperature difference of energy transmission, and can not be greatly improved, so as to reduce irreversible loss, Effects of COP improvement and thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

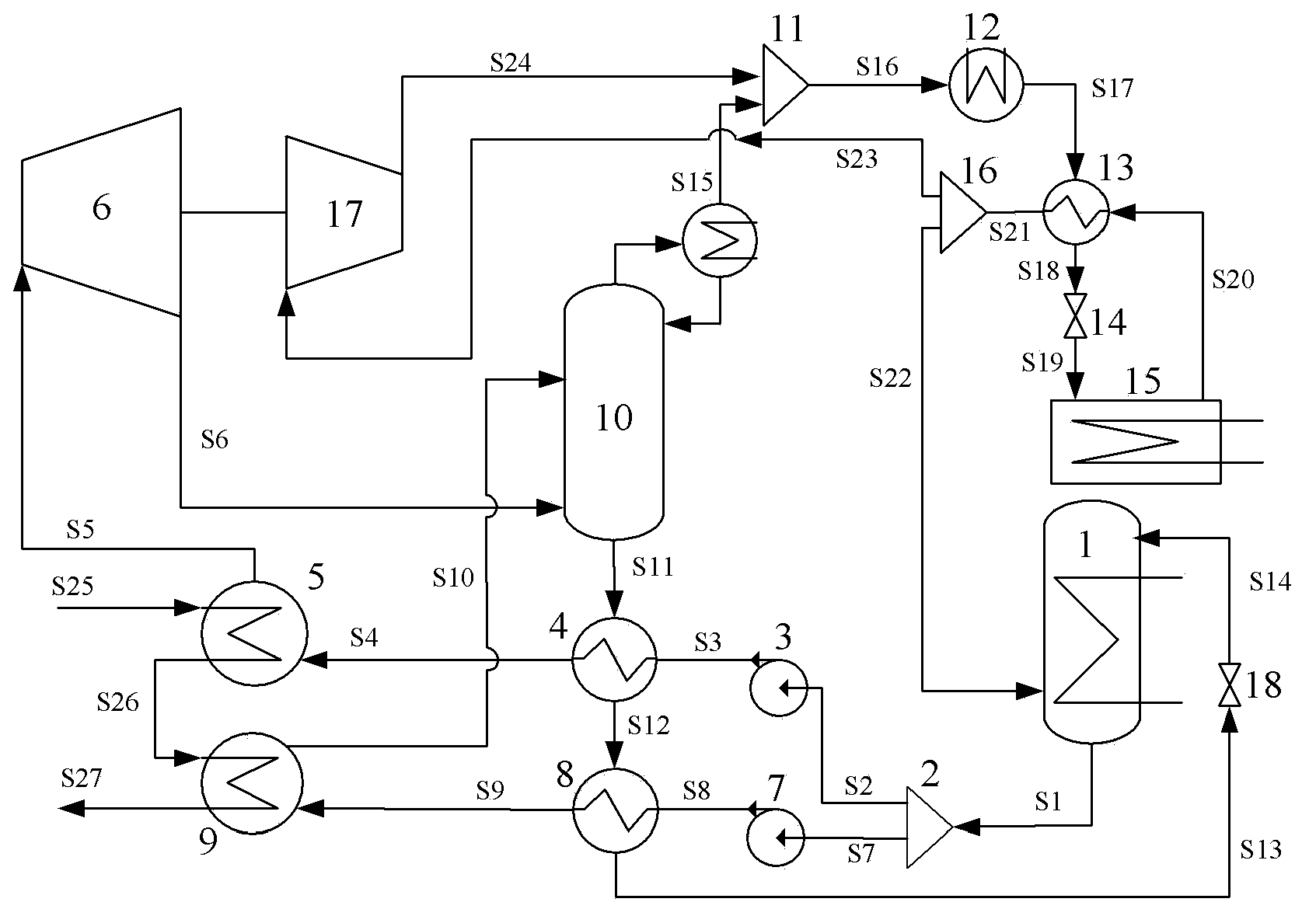

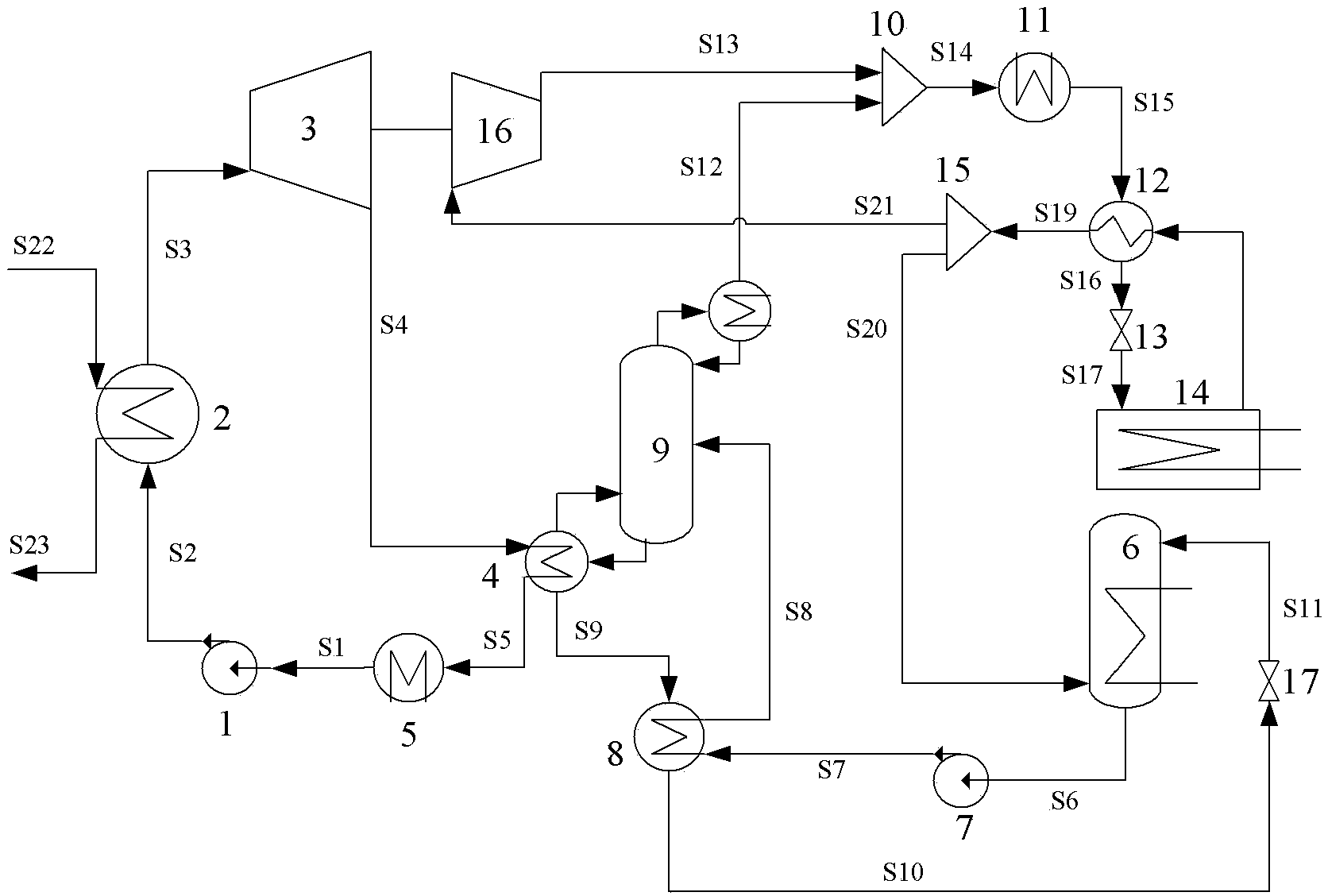

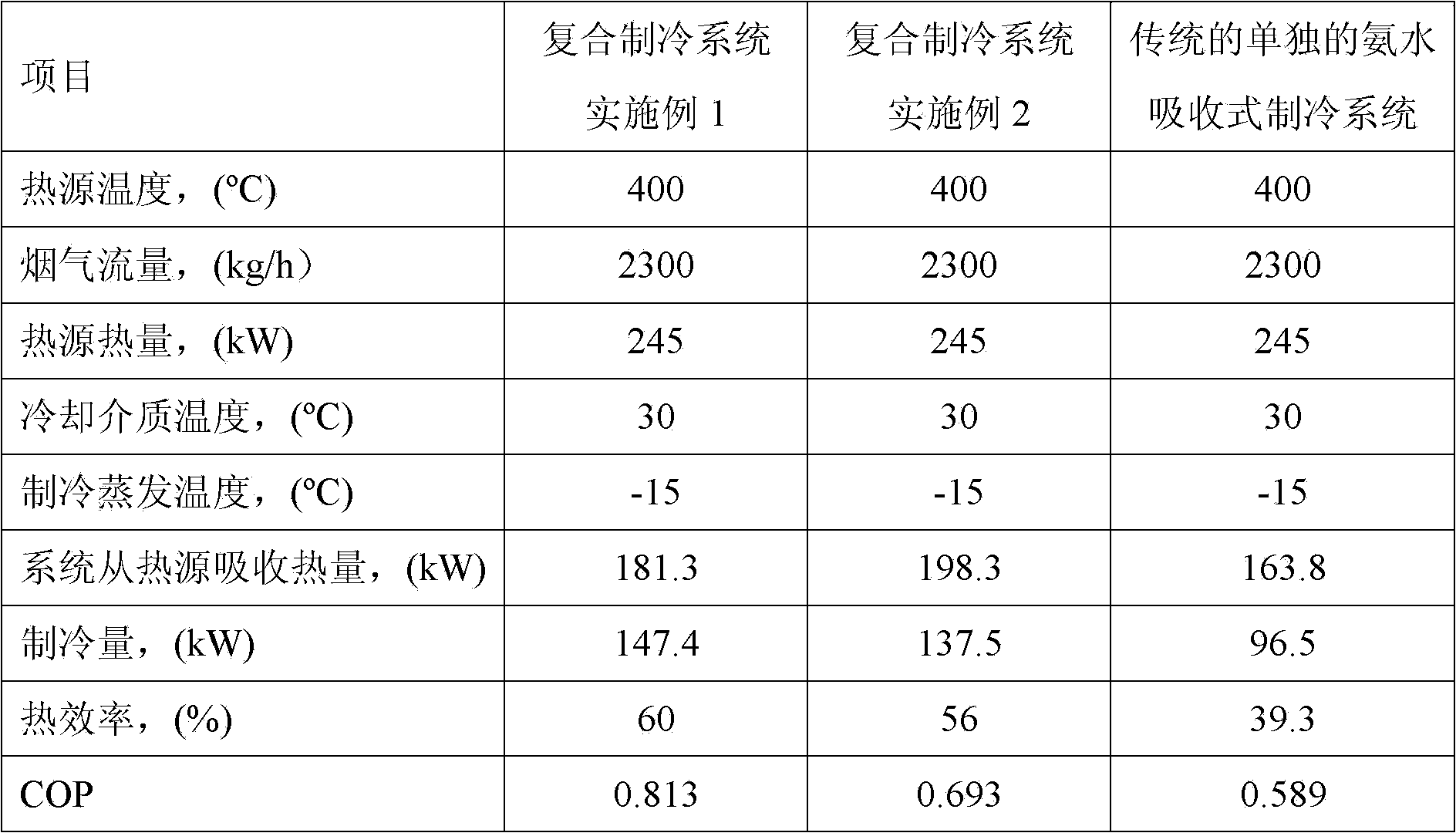

[0036]The invention provides a compound refrigeration system and method based on forward and reverse cycle coupling, using medium and low temperature waste heat or solar energy as a driving heat source. The system includes three sub-cycles, which are work sub-cycle, absorption refrigeration sub-cycle and compression refrigeration sub-cycle. The higher temperature part of the medium and low temperature heat source is used to drive the work sub-cycle to do work, and the lower temperature waste heat is used to drive the absorption refrigeration cycle. Refrigeration, while the heat exhausted by the work sub-cycle is also recycled by the absorption refrigeration sub-cycle, and the work done by the work sub-cycle drives the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com