Real-time monitoring method of coal mine shaft frozen wall temperature based on fiber Bragg grating sensing

A fiber grating and frozen wall technology, which is applied to thermometers, thermometers, and thermometer parts that undergo physical/chemical changes, can solve the problems of inability to reflect the development of frozen walls, difficulty in online real-time monitoring, and high technical difficulty in maintenance. Achieve the effect of avoiding and reducing wrong construction decisions, avoiding local temperature disturbances, and monitoring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

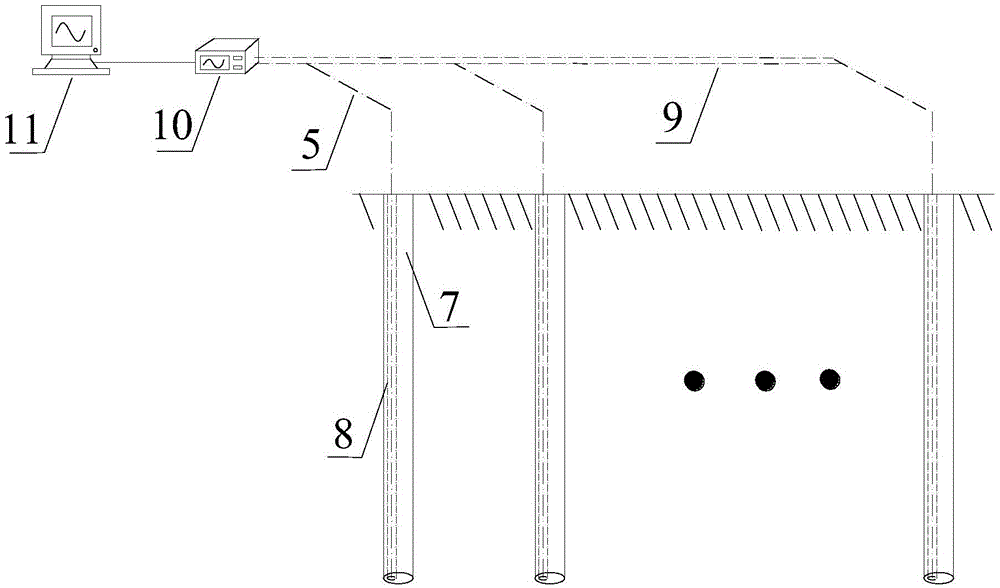

[0028] Embodiment 1: The present invention is based on the coal mine shaft frozen wall temperature real-time monitoring method of fiber grating transmission, comprising the following steps:

[0029] Step 1. Reasonably design the fiber grating sensing device according to the construction conditions of the coal mine shaft:

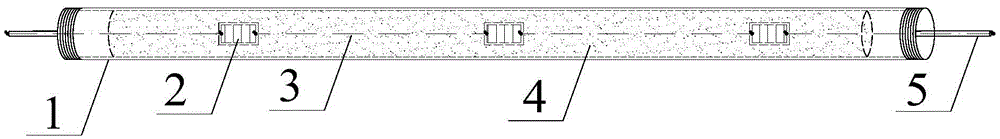

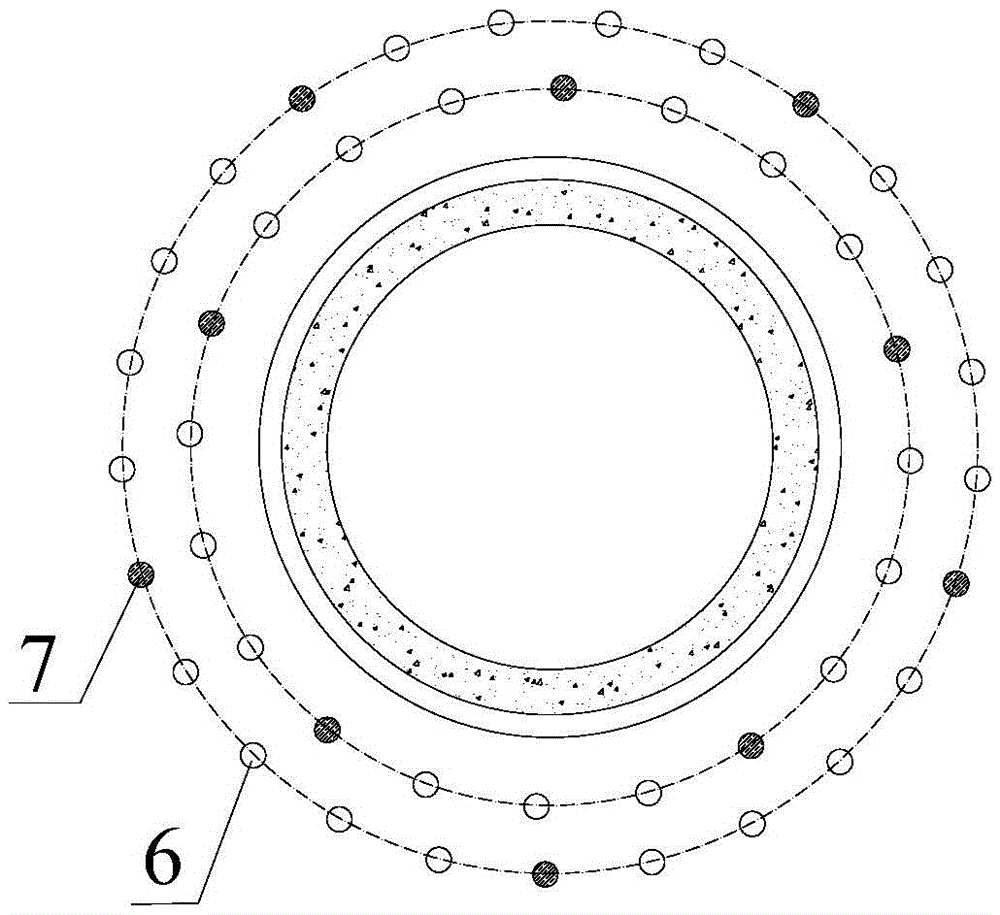

[0030] A. The seamless steel pipe 1 with both ends of the thread is used as the fiber grating sensing carrier and protection tube. In order not to affect the freezing effect and improve the detection accuracy, because the freezing hole diameter is generally 160-200mm, the seamless steel pipe specification is generally selected outside the nominal size. For a low-carbon steel seamless steel pipe with a diameter of 32mm, a wall thickness of 8mm, and a length of 10m, the specification parameters of the steel pipe can be appropriately adjusted according to the actual diameter of the freezing hole, and the corresponding high-leakage-proof optical fiber joint 5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com