Electrified railway-used bar-shaped column type porcelain polymer composite insulator and preparation method thereof

A technology for electrified railways and composite insulators, applied to circuits, insulators, electrical components, etc., can solve problems affecting the safe operation of composite insulators, damage to sheaths, end seals, and reduced utilization of creepage distances, and achieve pollution flashover characteristics Best, prevents brittle fracture accidents, excellent water repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

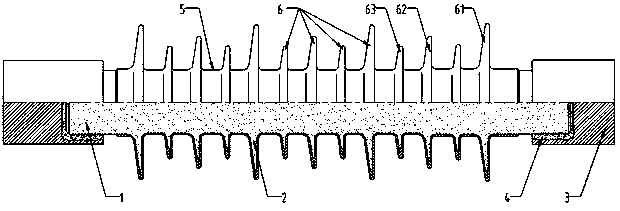

[0057] A method for preparing a rod-shaped column type porcelain-polymer composite insulator for electrified railways, the method comprising the following steps:

[0058] (1) Select the corresponding structural mold and install it on the processing equipment to be processed and produced.

[0059] (2) Insert the porcelain mandrel into the central hole of the metal fitting, and then glue it together with an adhesive to obtain a porcelain mandrel-metal fitting composite; the adhesive can be cement or resin.

[0060] (3) In step (2), the surface of the ceramic mandrel of the ceramic mandrel-metalware composite is pretreated with a coupling agent; the coupling agent can be a coupling agent such as Camrock series 607 or 608;

[0061] (4) Put the pretreated porcelain mandrel-metal fitting composite obtained in step (3) into the corresponding position in the mold;

[0062] (5) Inject the hydrophobic cycloaliphatic epoxy resin into the mold and perform the first curing. The gel time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com