Array substrate and display device

A technology for array substrates and display devices, applied in semiconductor devices, electric solid state devices, electrical components, etc., can solve problems such as affecting the deposition effect of metal thin films, poor adhesion, and affecting semiconductor characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

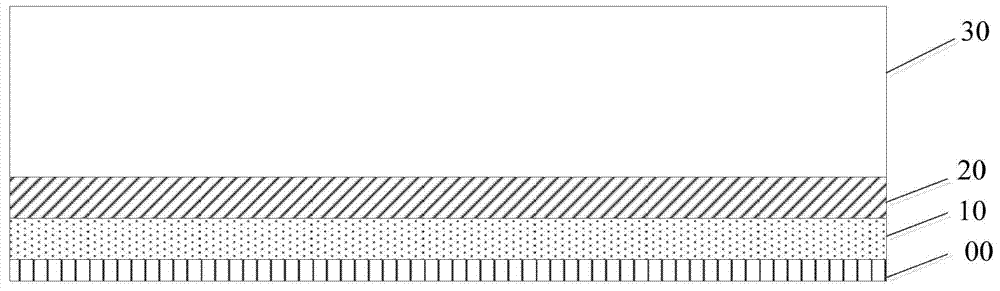

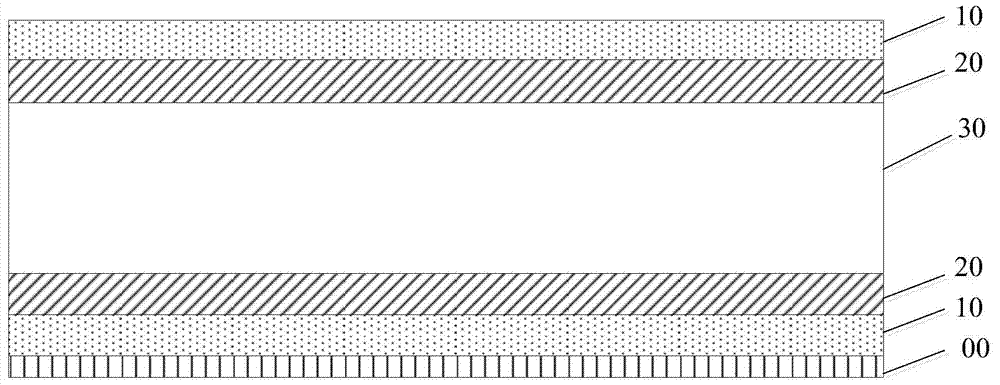

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

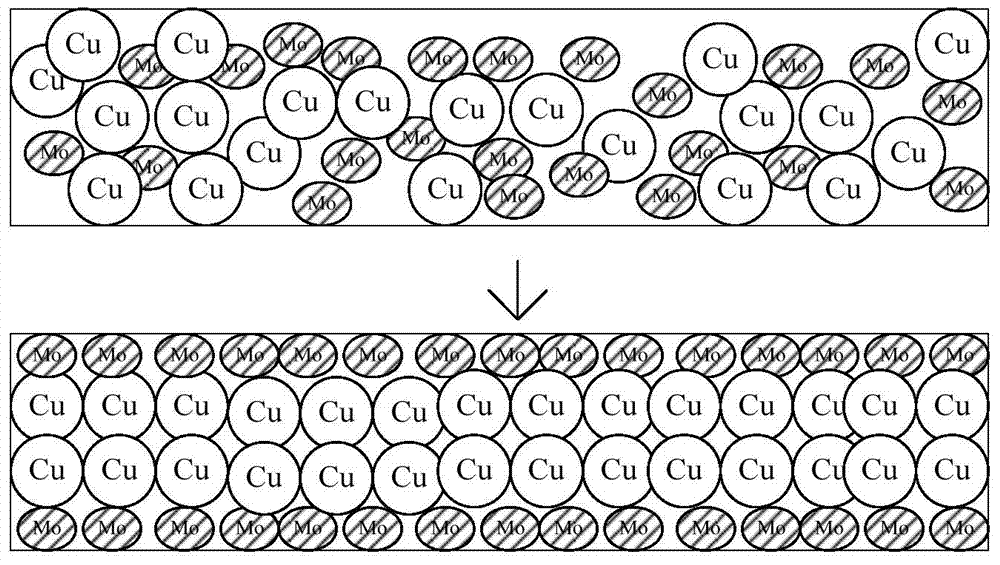

[0026] At present, when metal Cu is used as the gate line in the display manufacturing industry, titanium (Ti), molybdenum (Mo), molybdenum-titanium alloy (MoTi) and other molybdenum alloys are usually used as the buffer layer of the array substrate. However, the buffer layer in the prior art has only one layer. In addition, because the materials of the metal film and the buffer layer are different, the etching speed is different, and the total time used for etching is mostly spent on corroding the buffer layer. The etch rate is slow, while the etch rate of the metal film is fast, which makes it difficult to control the slope angle after etching.

[0027] An embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com