Method for removing GaN-based epitaxial layer on substrate

A technology of epitaxial layer and substrate, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unsuitable patterned substrates, high polishing precision requirements, substrate lattice damage, etc., and achieve good uniformity of photoelectric parameters , crystal quality is good, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

[0026] The invention provides a method for removing a GaN-based epitaxial layer on a substrate, wherein the substrate and the GaN-based epitaxial layer on the substrate form an epitaxial wafer. The present invention uses chlorine (CL 2 ) to etch away the GaN-based epitaxial layer on the substrate, thereby obtaining a substrate from which the GaN-based epitaxial layer has been removed.

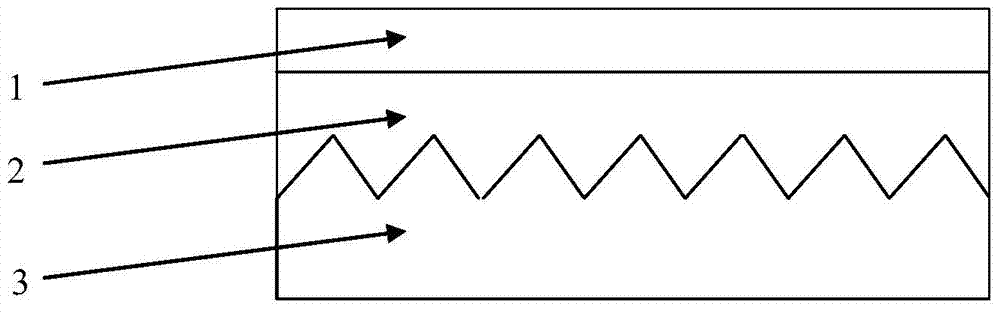

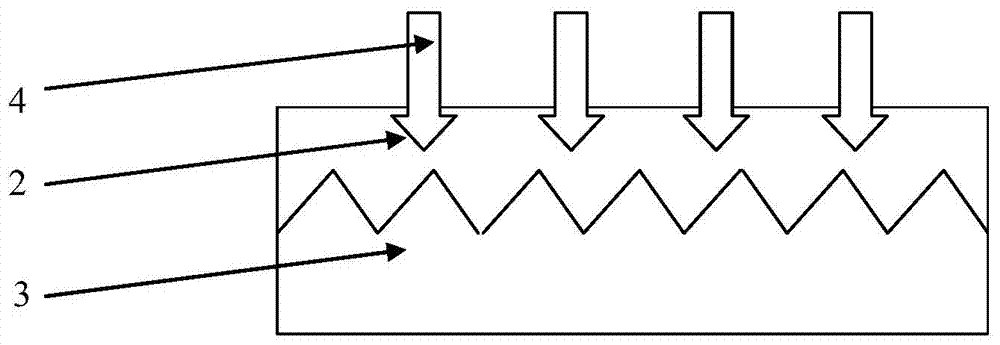

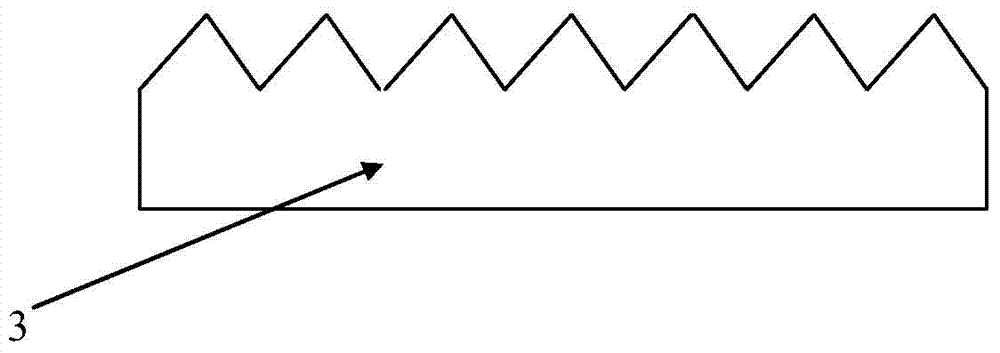

[0027] figure 1 A schematic cross-sectional view of an epitaxial wafer that may be used in one embodiment of the invention is shown. As those skilled in the art can understand, an epitaxial wafer refers to a structure in which an epitaxial layer 2 is grown on a substrate 3 , including a structure in which epitaxial materials are attached to other substrates or pedestals. In some embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com