Slag and metal separation device of external electric field between slag and metal

A technology of slag gold separation and applied electric field, which is applied in electrostatic effect separation, solid separation, chemical instruments and methods, etc. It can solve the problems of the impact of the development of the recycled non-ferrous metal industry, the lack of effective means of slag gold separation and recovery of metals, etc., and achieve a concise structure. , The effect of strong slag corrosion resistance and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

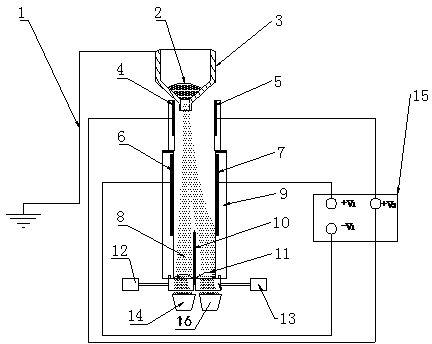

[0030] In this example, see figure 1 , a slag-gold separation device with an external electric field applied between the slag-gold, consists of a feeding device, a slag-gold physical separation system and a recovery system, the feeding device includes a slag hopper 3 and its feeding control system, and the slag-gold physical separation system consists The gold separation bin 9 and the electric field generation system are composed of the slag hopper 3 arranged above the slag-gold separation bin 9, the slag hopper 3 is loaded with the slag-gold mixture 2, and the interior of the slag-gold separation bin 9 is a vertical material gravity channel, and the electric field is generated The system includes a group of two polar plates of the same polarity and a group of polar plates of different polarities. In the slag-gold separation chamber 9, a positive potential area space and an electric field action area space are sequentially generated from top to bottom. The polar plate provides...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

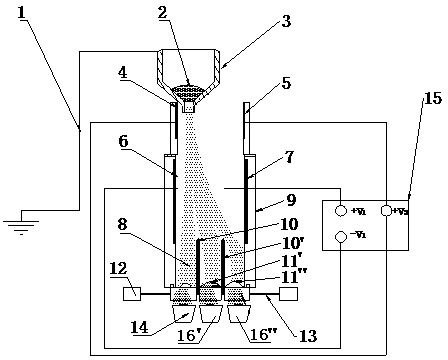

[0036] In this example, see figure 2, at the bottom of the slag-gold separation chamber 9, a particle size grading baffle is set in the metal recovery area, which is the regenerated metal particle size grading baffle 10', and the regenerated metal particle size grading baffle 10' is arranged in parallel with the slag-gold separation baffle 10 The recycled metal particle size grading baffle plate 10' divides the metal recovery area into two particle size grading metal recovery areas, the residual metal particles 11 in the slag-gold mixture 2 are offset and fall toward the direction of the positive electrode plate 7, and the slag-gold mixture 2 passes through as a whole After the electric field action area, under the action of the electric field, the slag 8 is separated from the residual metal particles 11, and the separated residual metal particles 11 cross the top of the slag-gold separation b...

Embodiment 3

[0038] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0039] The cathode electrode 6 and the anode electrode 7 have the same structure, and the cathode electrode 6 and the anode electrode 7 can move up and down along the inner wall of the slag-gold separation chamber 9, so that the height position of the electric field action area in the slag-gold separation chamber 9 can be adjusted as required , to meet different slag-gold separation requirements, combined with voltage control, it can further meet the needs of separation of different metal particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com