Acid pickling process and acid pickling system for active carbon

A technology of activated carbon and pickling, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of low automation, low efficiency and complex structure of pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

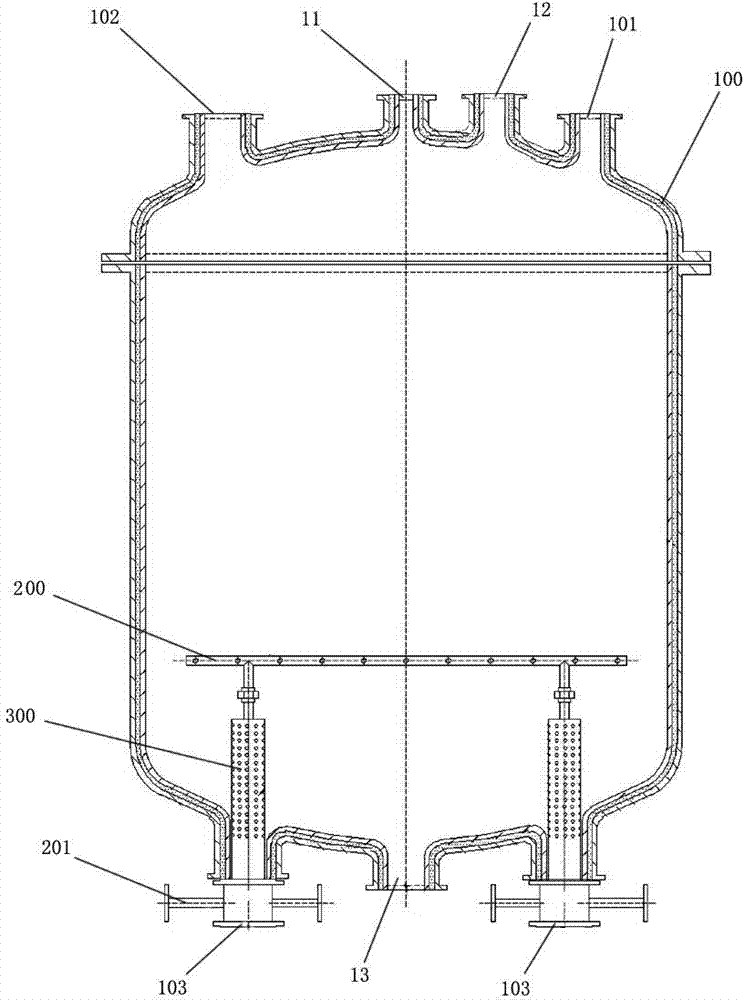

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

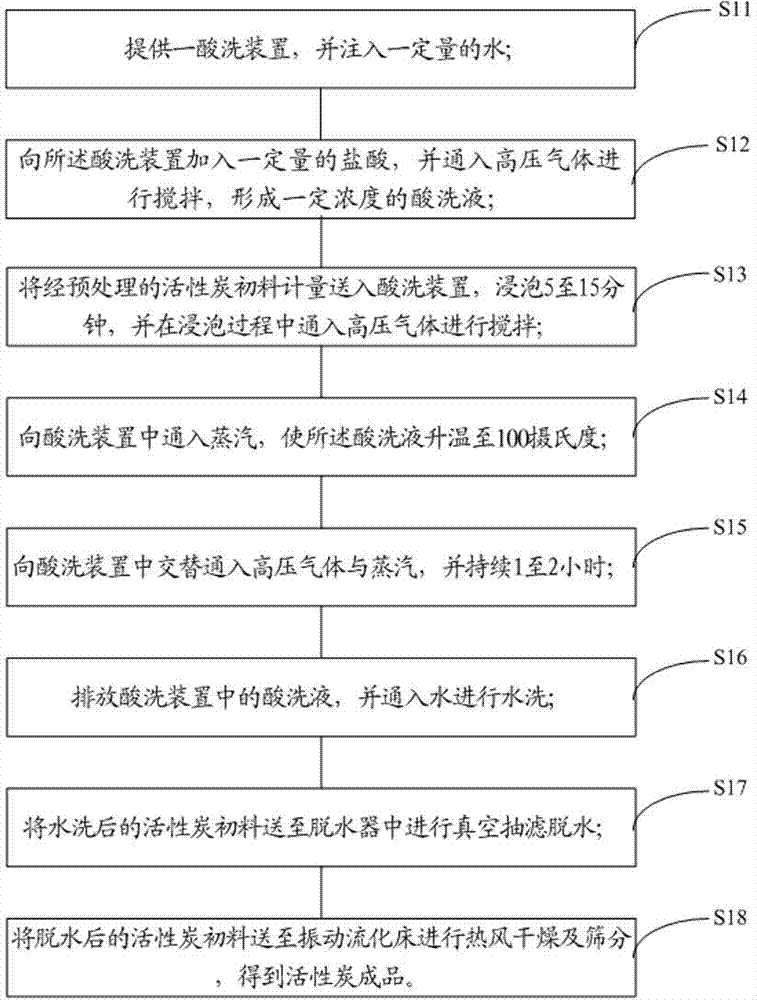

[0022] figure 1 It is a schematic flow chart of a specific embodiment of the present invention. Such as figure 1 Shown, a kind of activated carbon pickling process comprises the steps:

[0023] Step S11, providing a pickling device and injecting a certain amount of water. The hydrochloric acid concentration is 3% to 8% by mass fraction, preferably 5%. Of course, the hydrochloric acid can also be replaced by other industrial acids such as hydrochloric acid, nitric acid, hydrofluoric acid and mixed acids, preferably hydrochloric acid is used as the acid for pickling. The water is domestic water that meets the water use standard, and the water described herein is the water of this standard, and of course it can also be water with higher purity such as deionized water.

[0024] Step S12, adding a certain amount of hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com