Aluminum oxide production method capable of optimizing process sequence

A production method and alumina technology, which are applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem that the concentration of AO in semen is difficult to effectively increase, and achieve convenient production organization, improved productivity, The effect of broad applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

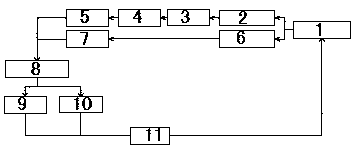

Image

Examples

Embodiment 1

[0021] (1) After batching the materials, prepare a slurry, add a sodium hydroxide solution with a mass concentration of 45%, react to dissolve the sodium aluminate slurry, and the temperature of the slurry after the sodium aluminate slurry is dissolved is 85°C;

[0022] (2) The sodium aluminate slurry at 85°C is directly introduced into the multi-effect circulating evaporator to evaporate the mother liquor, and the temperature of the slurry in the evaporator spontaneously drops to 65°C during the evaporation process of the slurry, and the AO concentration is 220g / l Sodium aluminate mother liquor;

[0023] (3) Decomposition: The sodium aluminate mother liquor with an AO concentration of 220 g / l at 65°C is directly subjected to step-by-step cooling of graded carbon, every 5°C is one level, and the temperature is gradually reduced to 45°C, and the decomposed The slurry is finely filtered to obtain aluminum hydroxide and circulating mother liquor; the circulating mother liquor is ...

Embodiment 2

[0028] (1) After batching the materials, prepare a pulp, add a 45% mass concentration sodium hydroxide solution, react to dissolve the sodium aluminate slurry, and the temperature of the slurry after the sodium aluminate slurry is dissolved is 75°C;

[0029] (2) The sodium aluminate slurry at 75°C is directly introduced into the multi-effect circulating evaporator to evaporate the mother liquor, and the temperature of the slurry in the evaporator spontaneously drops to 60°C during the evaporation process of the slurry, and the AO concentration is 210g / l Sodium aluminate mother liquor;

[0030] (3) Decomposition: The sodium aluminate mother liquor with an AO concentration of 210 g / l at 60°C is directly subjected to step-by-step cooling of the graded carbon, with every 5°C as one level, step-by-step cooling and decomposition to 40°C, and the decomposed The slurry is finely filtered to obtain aluminum hydroxide and circulating mother liquor; the circulating mother liquor is evapo...

Embodiment 3

[0035] (1) After batching the materials, prepare a slurry, add a sodium hydroxide solution with a mass concentration of 45%, react and dissolve the sodium aluminate slurry, and the temperature of the slurry after the sodium aluminate slurry is dissolved is 80°C;

[0036] (2) The sodium aluminate slurry at 80°C is directly introduced into the multi-effect circulating evaporator to evaporate the mother liquor, and the temperature of the slurry in the evaporator spontaneously drops to 70°C during the evaporation process of the slurry, and the AO concentration is 205g / l Sodium aluminate mother liquor;

[0037] (3) Decomposition: The sodium aluminate mother liquor with an AO concentration of 205 g / l at 70°C is directly subjected to step-by-step cooling of graded carbon, every 5°C is one level, and the temperature is gradually reduced to 45°C, and the decomposed The slurry is finely filtered to obtain aluminum hydroxide and circulating mother liquor; the circulating mother liquor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com