Device for adding polyethylene oxide in papermaking process

A polyethylene oxide and paper machine technology, which is applied in the pulp raw material addition process, papermaking, textiles and papermaking, etc., can solve the problems of polyethylene oxide waste, high unit consumption per ton of paper, shutdown loss, etc., and achieve reduction The effect of manufacturing cost, reducing consumption per ton of paper, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

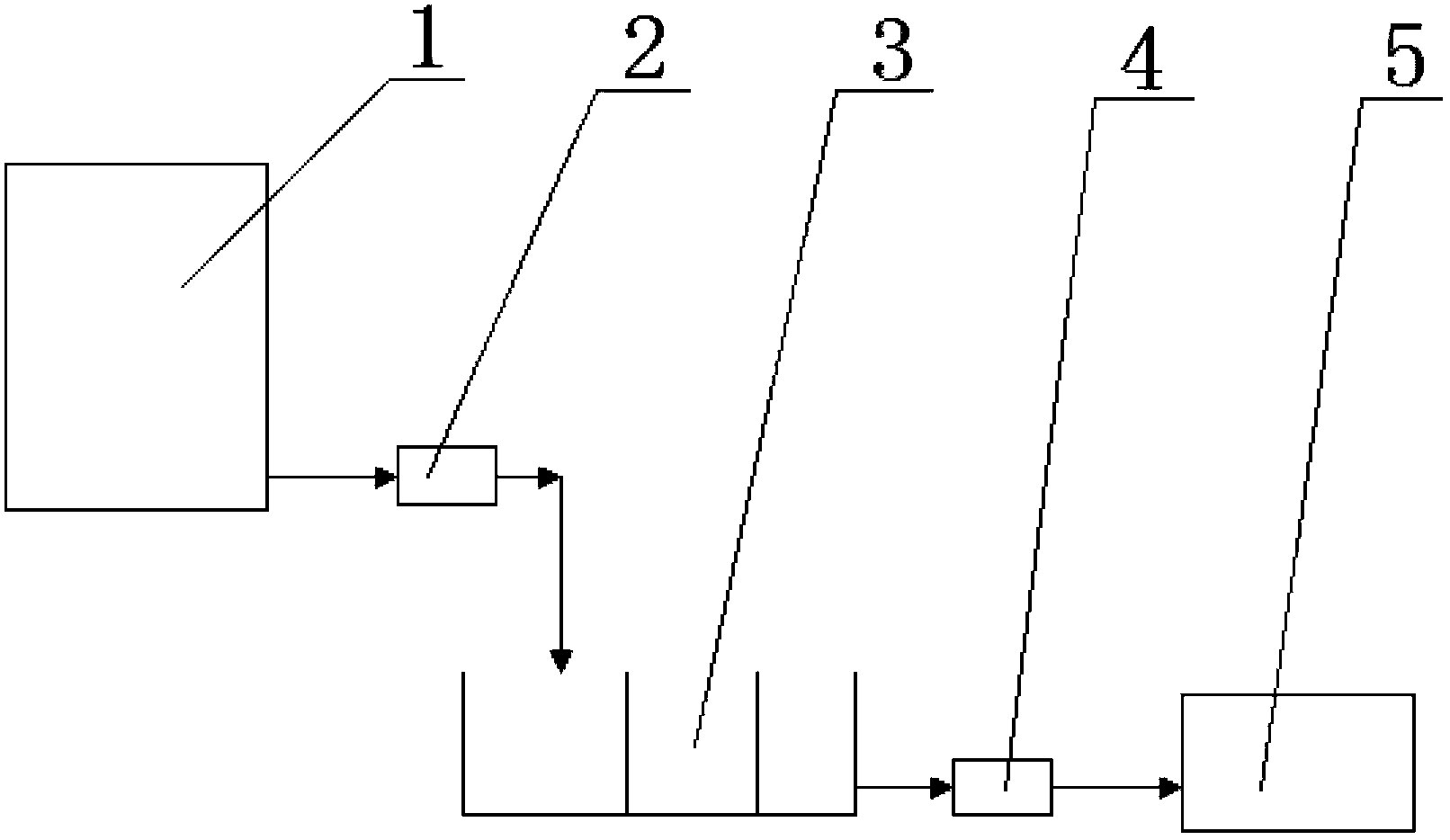

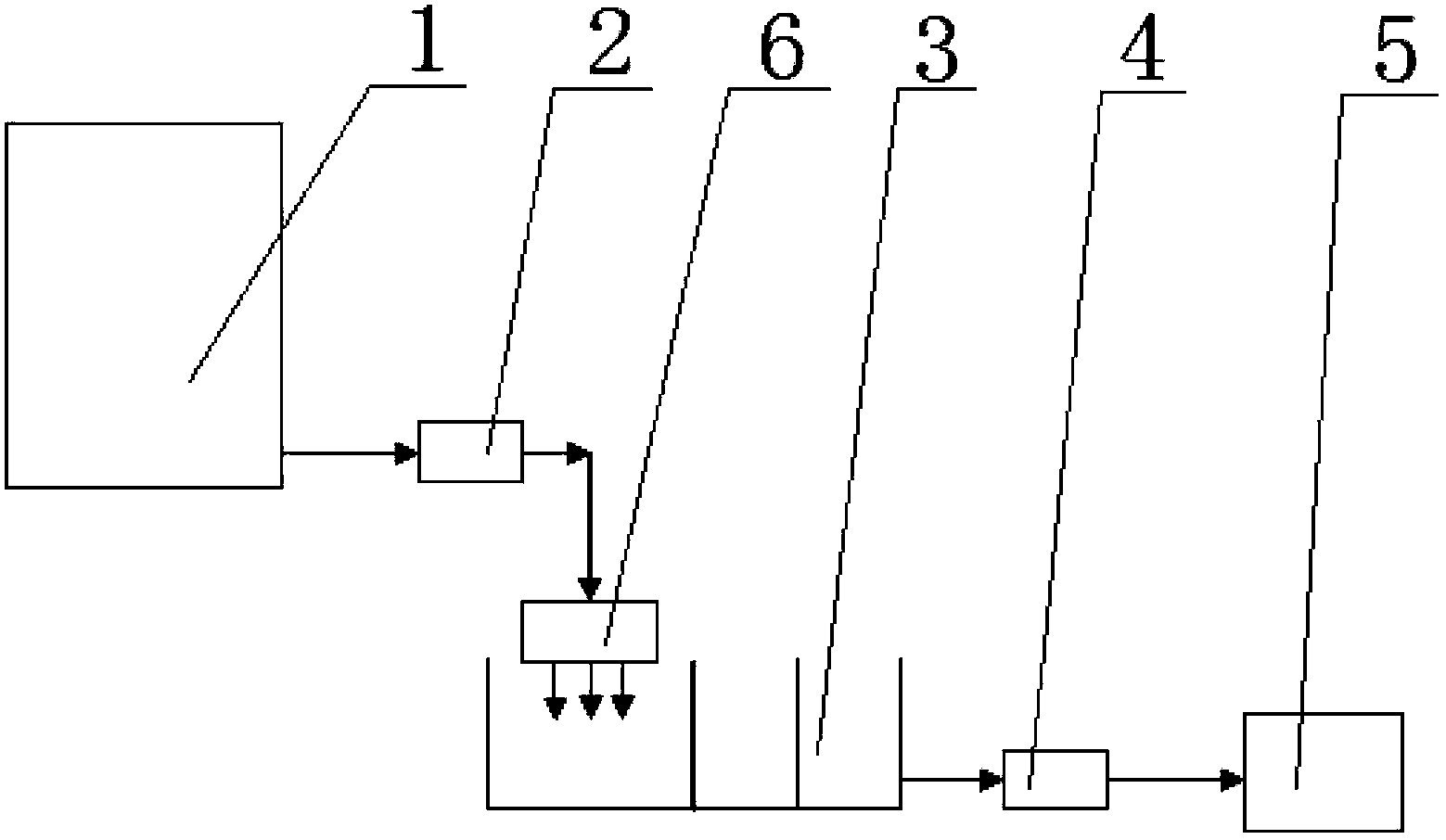

[0022] A device for adding polyethylene oxide in papermaking, with a structure such as figure 2 As shown, the device comprises a polyethylene oxide dissolving tank 1, a first screw pump 2, a polyethylene oxide dilution tank 3, a second screw pump 4 and a paper machine headbox 5 connected in sequence, and the first screw pump 2 and the polyethylene oxide dilution tank 3 are provided with a filter screen 6; the filter screen 6 is a stainless steel filter screen with an aperture of 60 mesh. Filter screen 6 is provided with cofferdam around, and cofferdam is a long 80cm, wide 80cm, high 10cm cuboid structure of making with common angle iron and steel plate, and this device exposes edge of angle iron along both sides, and then in polyepoxy Make the steel frame that spacing is 80cm on the ethane dilution tank 3, be used for placing this filter screen 6.

[0023] The device of the present invention makes the polyethylene oxide pass through the filter screen 6 after coming out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com