Biomass particle burner

A technology of biomass pellets and burners, which is applied in the direction of combustion methods, combustion equipment, fuel supply, etc., can solve the problems of high labor intensity for operators, poor control of firepower, and inability to automatically feed materials, so as to facilitate popularization and implementation, and is easy Procurement, the effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

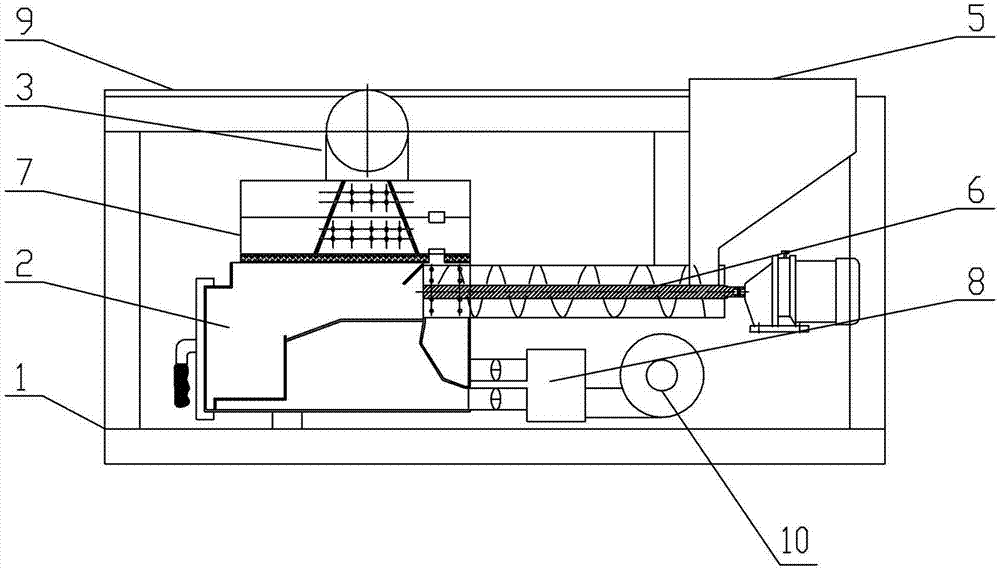

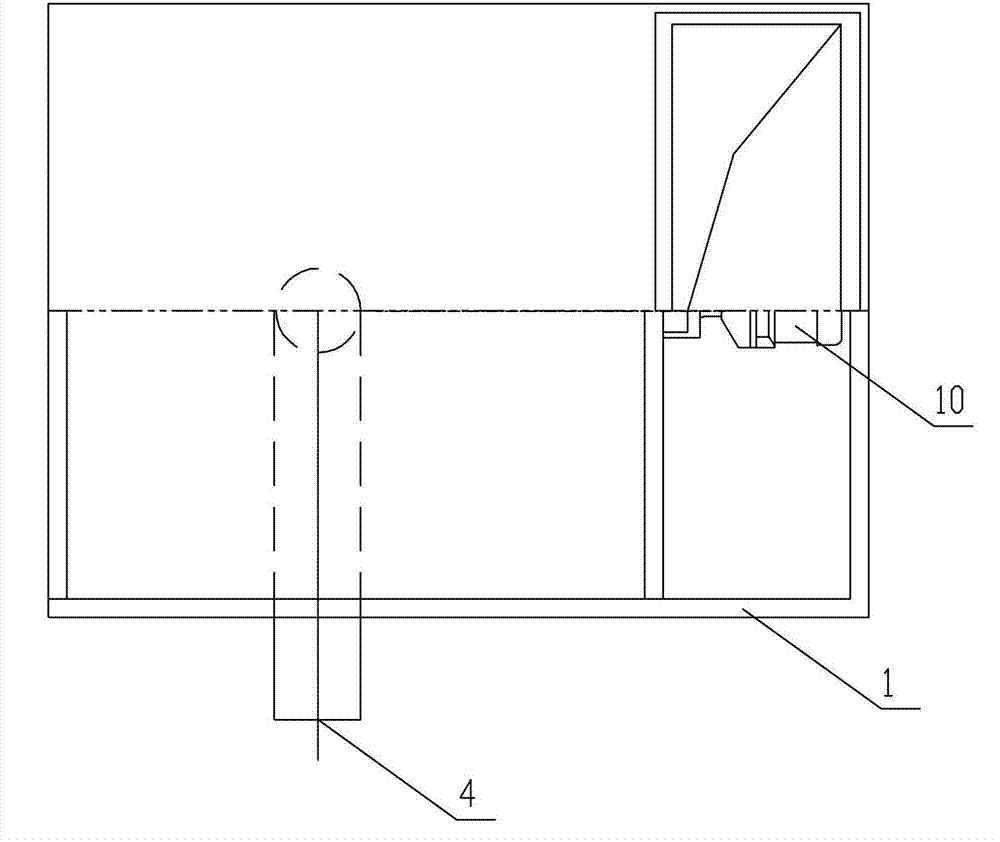

[0020] see figure 1 , figure 2 , in the figure, the biomass particle burner of the present invention includes an outer frame 1, a combustion device 2 is installed in the lower part of the outer frame, a furnace 3 is arranged on the upper part of the outer frame and above the combustion device, and the outer surface of the furnace is connected horizontally with a flame outlet pipe 4. A material box 5 is provided on one side of the outer frame, and a spiral automatic feeding device 6 is provided at the discharge port of the material box. The discharge port of the spiral automatic feeding device is connected with the combustion device, and the combustion device and the furnace Two or three air intake devices 7 are arranged between them, and an oxygen-adding regulating device 8 is connected to the bottom side of the combustion device.

[0021] The screw automatic feeding mechanism includes a horizontal feeding pipe located at the outlet of the material box, a screw rod and blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com