A kind of titanium tetrachloride preheater

A technology of titanium tetrachloride and preheater, which is applied in the direction of titanium dioxide, heat exchanger type, indirect heat exchanger, etc., can solve problems such as uneven heating of coils, corrosion of coil materials, and low thermal efficiency of preheaters. Achieve the effect of avoiding low utilization rate and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Adopt the titanium tetrachloride preheater of the present invention to meet the capacity of 60,000 tons / year chlorination titanium dioxide device

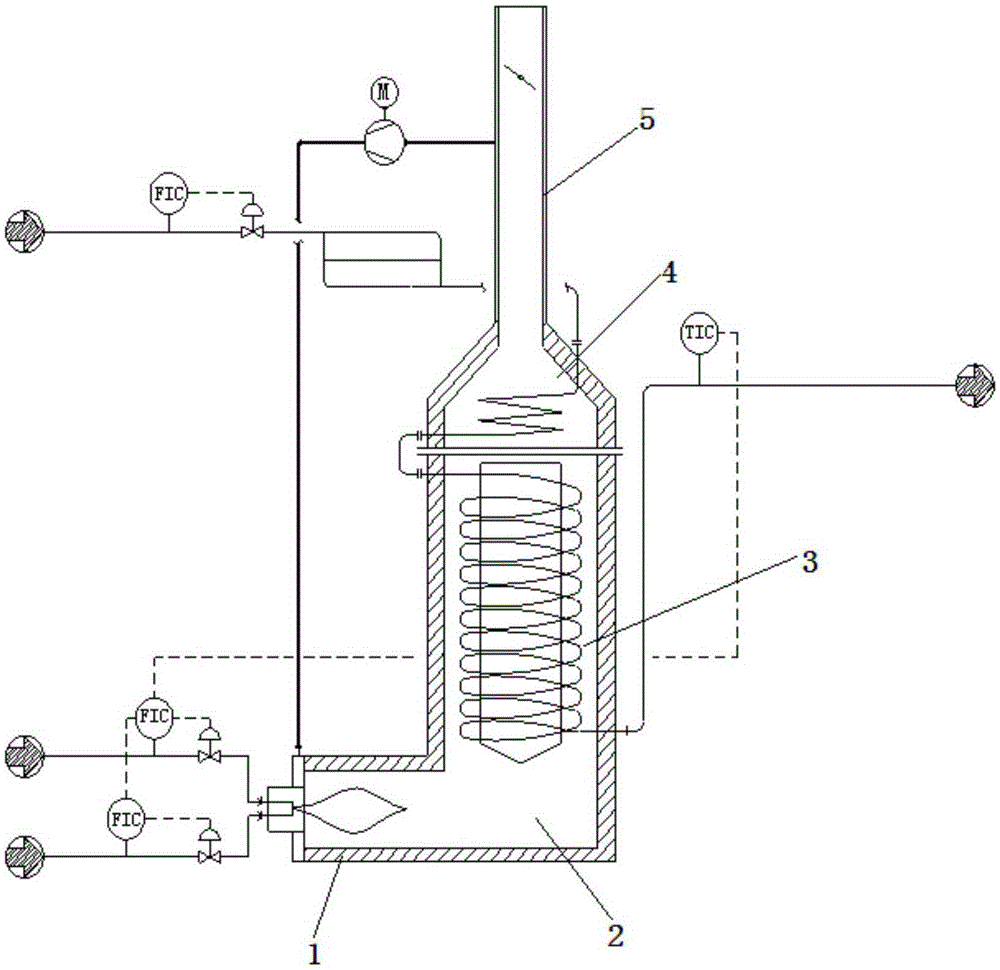

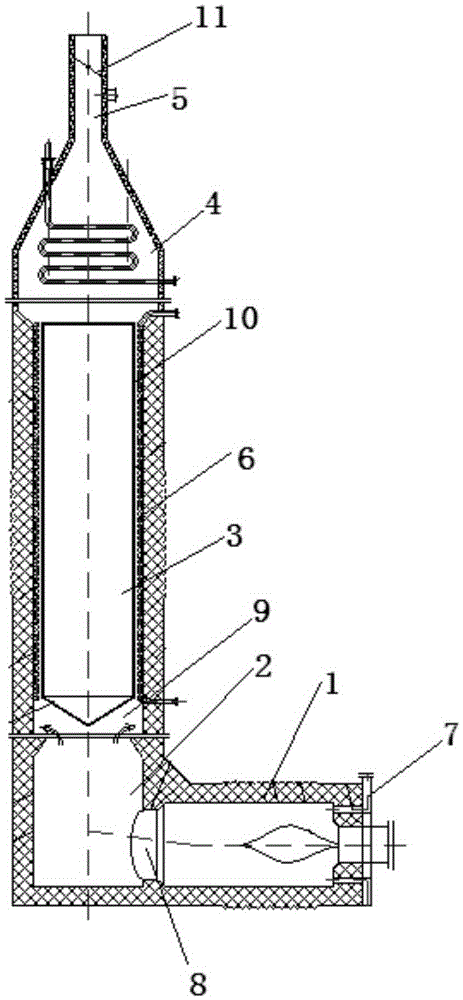

[0017] (1) Technological process: the high-temperature gas (1400°C) produced by the combustion of fuel gas and air enters the combustion section, and the low-temperature chimney tail gas (about 200°C) is introduced into the combustion chamber through the circulating fan, and enters the tetrachloride together with the high-temperature gas The mixing section of the titanium preheater, after mixing evenly, enters the convection section to heat the coil, the flue gas after heat exchange enters the preheating section for further heat exchange and preheating, titanium tetrachloride liquid is sent from the outside, and finally the tail gas is discharged from the top chimney; Titanium tetrachloride medium enters the coil to exchange heat with high-temperature flue gas through countercurrent, first enters the preheating ...

Embodiment 2

[0019] Embodiment 2: Adopt the titanium tetrachloride preheater of the present invention to meet the capacity of 100,000 tons / year chloride titanium dioxide plant

[0020] (1) Technological process: the high-temperature gas (1400°C) produced by burning fuel gas and air through the burner enters

[0021] In the combustion section, the low-temperature chimney exhaust gas (about 200°C) is introduced into the combustion chamber through the circulating fan, and enters the mixing section of the titanium tetrachloride preheater together with the high-temperature gas, and enters the convection section to heat the coil after mixing evenly. The flue gas enters the preheating section for further heat exchange and preheating. Titanium tetrachloride liquid is sent from the outside, and finally the tail gas is discharged from the chimney at the top; After the hot section is preheated, it enters the convection section for gasification and superheating, and is finally heated to the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com