Motor/air-hydraulic load simulator system

A load simulator and load simulation technology, applied in the field of simulators, can solve the problems of no motor/pneumatic-hydraulic flexible loading system, small output torque of electric load simulator, poor operation accuracy of pneumatic load simulator, etc., to shorten the development cycle , good dynamic characteristics, and the effect of saving research and development funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

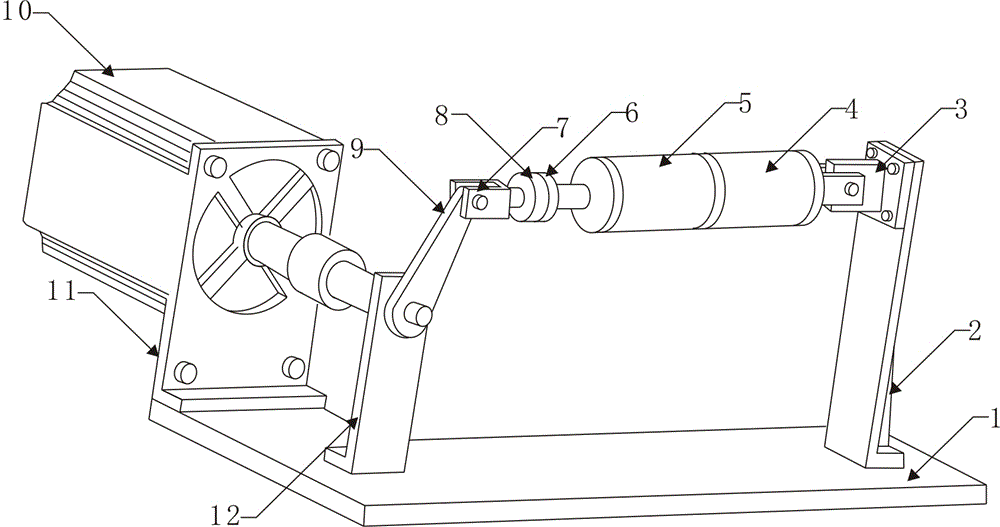

[0021] Embodiment 1: The motor 10 drives the crank rocker 9 to swing at a certain frequency and angle, and the air-liquid cylinder (4, 5) loads the rudder with a certain regular force, and the pressure sensor 8 collects the magnitude of the loading force, and the displacement sensor 6 Collect the displacement signal. In this example, the motor 10 is the load simulation part, and the gas-hydraulic cylinder is the active loading part. The gas-hydraulic cylinder is combined in series by the hydraulic cylinder 4 and the pneumatic cylinder 5; therefore, this loading method is called gas-liquid Cylinder-motor load simulation system operation mode.

[0022] The working process of this embodiment: according to the frequency and angle swing that the crank rocker 9 needs to achieve, the motor 10 is controlled so that the motor 10 gives the specified motion of the crank rocker 9 . According to the magnitude and frequency of the force load between the crank rocker and the air-hydraulic cy...

Embodiment 2

[0023] Embodiment two: the gas-hydraulic cylinder drives the crank rocker 9 to swing at a certain frequency and angle, the motor 10 carries out a certain regular force loading on the rudder plate, the pressure sensor 8 collects the magnitude of the loading force, and the displacement sensor 6 collects the displacement signal, In this example, the motor 10 is the load simulation part, and the air-hydraulic cylinder is the active loading part. The air-hydraulic cylinder is connected in series by the hydraulic cylinder 4 and the pneumatic cylinder 5, so this loading method is called motor-air-hydraulic cylinder load simulation. How the system works.

[0024] The working process of this embodiment: according to the required frequency and angle swing of the crank rocker, the displacement of the air-hydraulic cylinder is controlled, so that the air-hydraulic cylinder gives the specified motion of the crank rocker. According to the magnitude and frequency of the force load between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com