Implantable side-pumping coupling method

A side-pumped and implanted technology, which is applied to laser components, electrical components, lasers, etc., can solve the problems of difficult process, increased product volume, and large impact, so as to solve the problem of thinning optical fibers, improving coupling efficiency, The effect of solving fiber warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

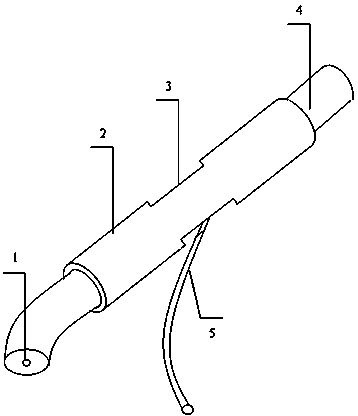

[0029] like figure 1 As shown, an implantable side pump coupling method includes a double-clad active fiber for generating laser light or amplifying laser light; and a multimode fiber 5 for connecting the pump source; the multimode fiber 5 The pump light is coupled into the double-clad active optical fiber by implanted side pumping method.

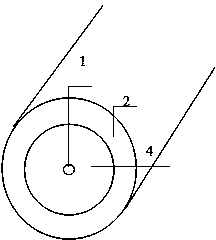

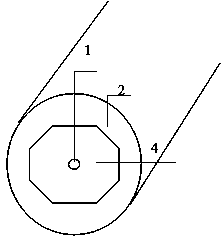

[0030] like figure 2 , image 3 , Figure 4 As shown, the double-clad active optical fiber includes a silica core 1 doped with rare earth ions, a pure silica inner cladding 4 and a low-refractive-index coating 2 . The refractive index of the coating of the double-clad active optical fiber is one of 1.31 and 1.37, and the curing method is ultraviolet curing or thermal curing.

[0031] The pure silica inner cladding shape of the double-clad active fiber is circular (such as figure 2 ), square (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com