Fire-fighting robot for transformer substation

A technology of fire-fighting robots and substations, applied in the field of robots, can solve the problems of small fires and major fire accidents, insufficient monitoring and early warning of fire hidden dangers, low probability of fire occurrence, etc., and achieve the effect of strengthening prevention and fighting and improving fire safety conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

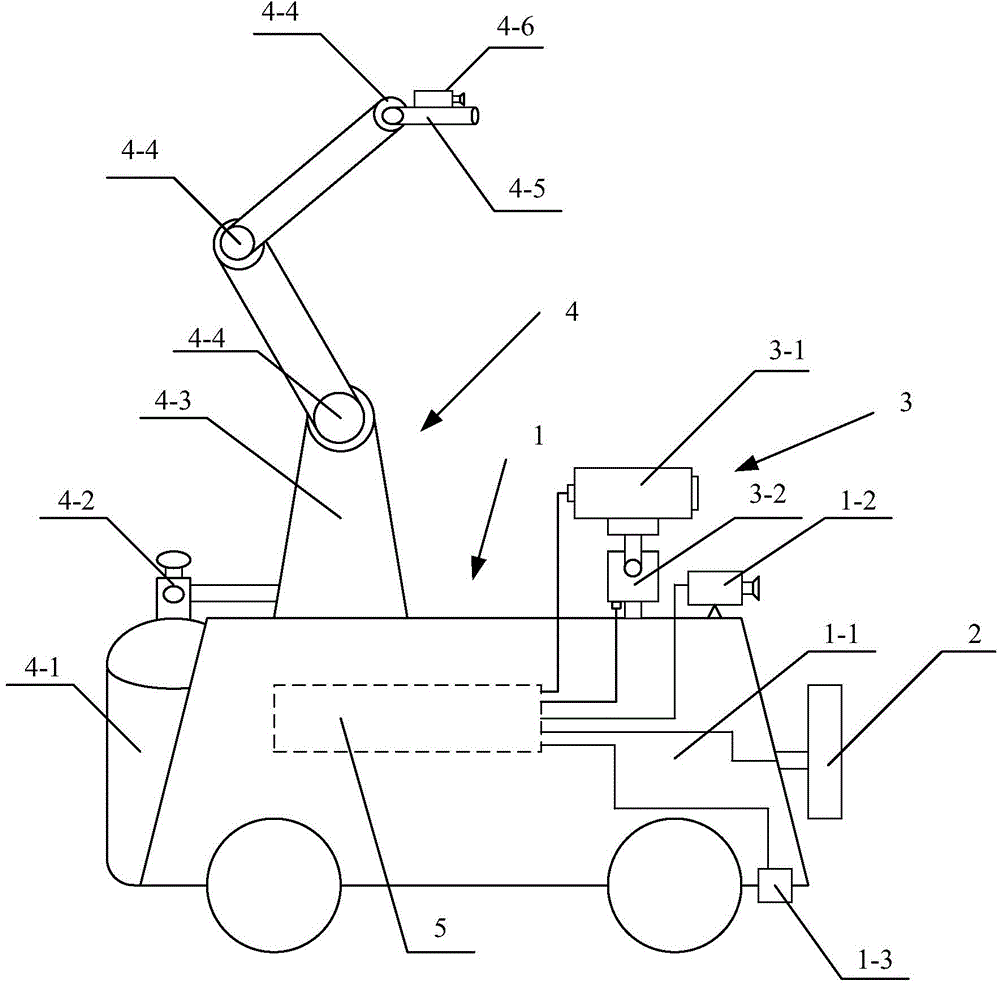

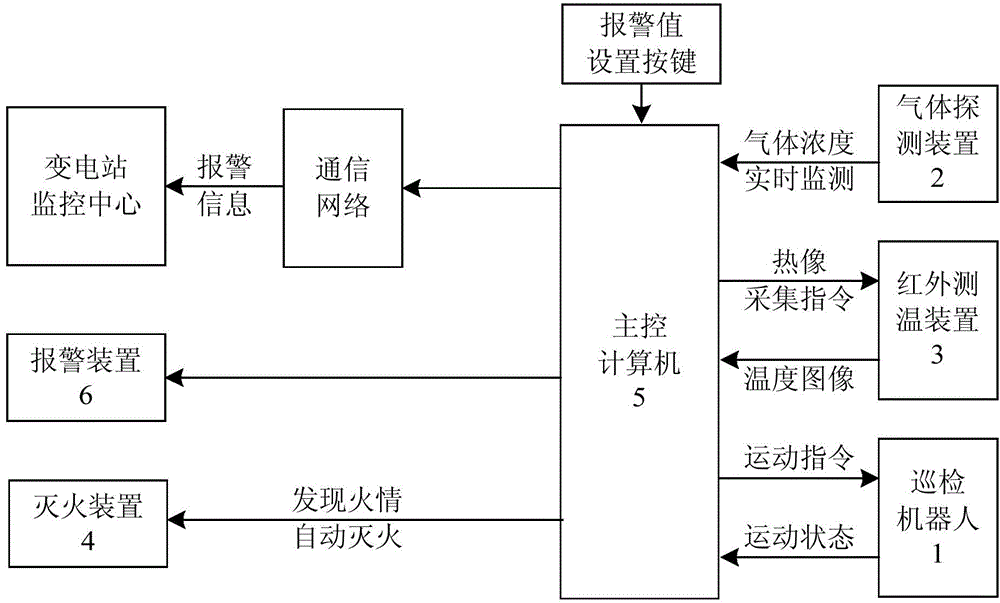

[0023] see figure 1 , The substation fire fighting robot of the present invention includes an inspection robot 1, a gas detection device 2, an infrared temperature measuring device 3, a fire extinguishing device 4 and a main control computer 5.

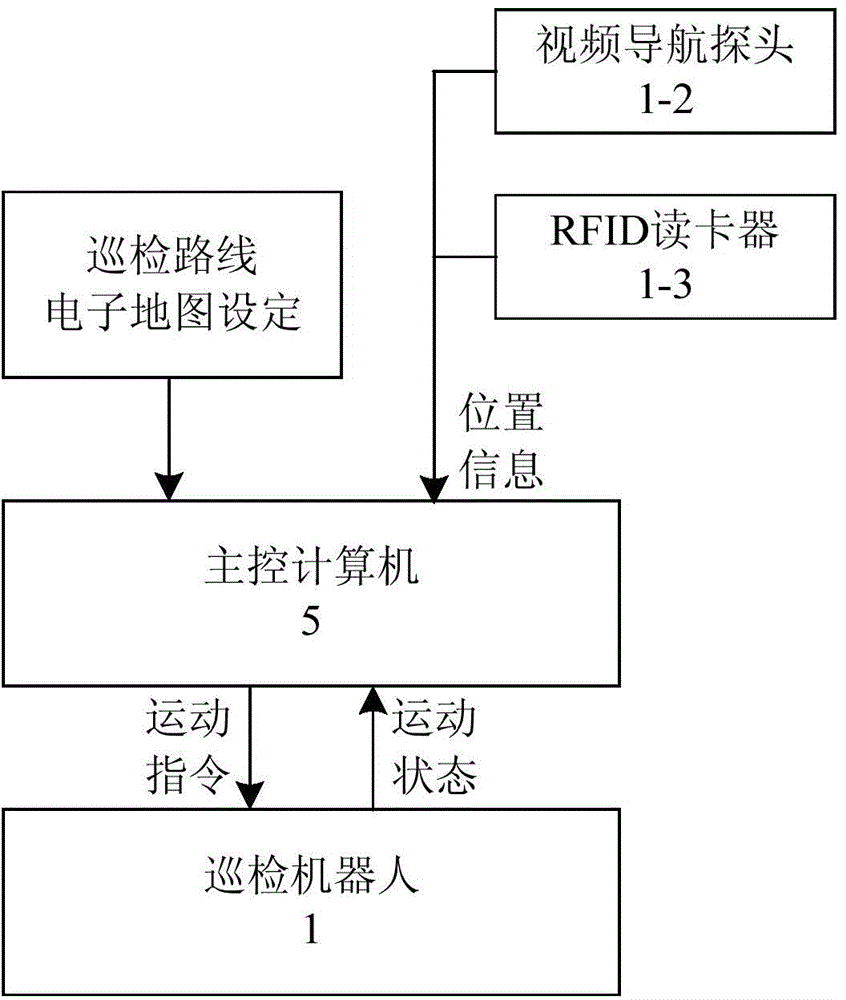

[0024] Among them, the inspection robot 1 is placed in the substation, the inspection route is drawn on the ground of the workplace of the inspection robot 1, and several radio frequency cards for positioning are installed at key points on the ground.

[0025] combined reference figure 2 , the inspection robot 1 includes a wheeled robot body 1-1, a video navigation probe 1-2 and an RFID card reader 1-3, the video navigation probe 1-2 is installed on the upper part of the robot body 1-1, and the RFID card reader 1 -3 is installed under the front part of the robot body 1-1 and corresponds to the radio frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com